50Amp 125V/250V Shore Power Inlet / Installation Instructions

FURRION 50 ampères 125V/250V / Installation de votre fi che

WARNING

ELECTRICAL SHOCK

AND FIRE HAZARD!

To prevent the risk of electrocu-

tion or fi re, ensure the inlet and

connecting cables are NOT con-

nected to a power source during

installation! Use only 6 AWG or

above cable with this product.

Using a smaller AWG cable will

result in overheating and possible

Fire Hazard.

Cable color scheme for 125/250V 4

core cables:

Black = Y - Live/Hot Cable

Red = X - Live/Hot Cable

White = W - Neutral Cable

Green = G - Ground Cable (8 AWG)

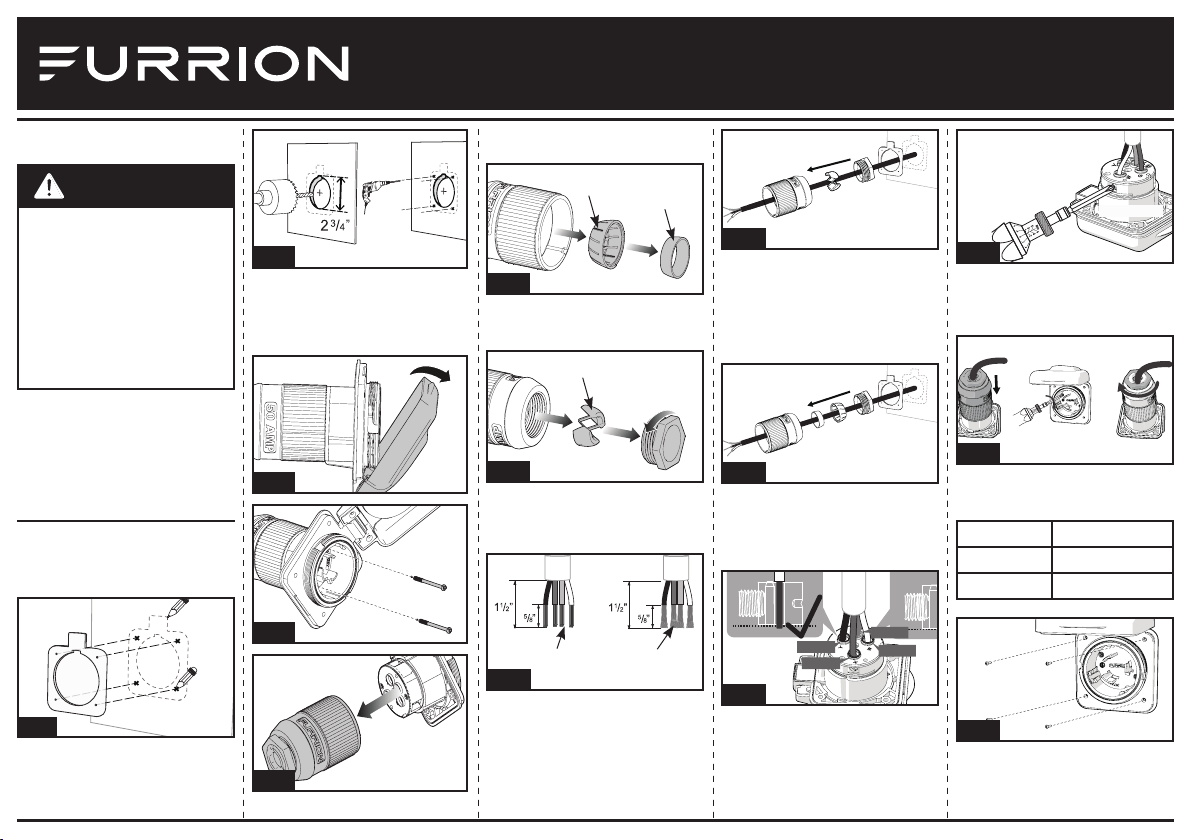

Installation

1. Select a suitable mounting position

for the power inlet. Mark a basic

outline for the inlet using the sup-

plied sealing gasket. (Fig. A)

Fig. A

2. Cut out the center circular hole

using a 2¾ ” hole saw and drill the

four mounting holes using a 1/8”

drill bit. (Fig. B)

Fig. B

3. Open the inlet cover and remove

the two screws holding the rear

housing. (Fig. C & Fig. D) Remove

the rear housing from the inlet.

(Fig. E)

Fig. C

Fig. D

Fig. E

4. Remove the strain relief insert

and the strain relief ring from the

inside of the rear housing. (Fig. F)

Fig. F

Strain Relief

Insert

Strain Relief

Ring

5. Rotate counterclockwise to remove

the strain relief nut and the cable

clip. (Fig. G)

Fig. G

Cable Clip

6. Strip off 1½” of the outer insula-

tion layer of the cable and 5/8” of

colored insulation from the ends of

the three conductor cables. (Fig. H)

Fig. H

Romex

Wire

Stranded

Core Wire

7. If you are using a Romex Wire,,

thread the cable through the sealing

gasket, strain relief nut, cable clip

and the rear housing. (Fig. I)

Fig. I

Required for Stranded Core Wire

only - If you are using a Stranded

Core Wire, thread the cable through

the sealing gasket, strain relief nut,

strain relief insert, strain relief ring

and the rear housing. (Fig. J)

Fig. J

8. Connect the colored wires to the

corresponding lettered holes on

the back of the inlet and tighten

the terminal screws to 22-25 in-lbs

torque. (Fig. K & Fig. L)

Black

Red

White

Red

White

Green

Black

Green

Fig. K

22-25 in-lbs

22-25 in-lbs

Fig. L

9. Replace the inlet rear housing and

secure with the two screws. Rotate

the rear cap clockwise to fi x the

cables. (Fig. M)

Fig. M

10. Fit the power inlet into the open-

ing and secure with four mounting

screws (not included). (Fig. N)

Housing Screw Size

Stainless KA3.5 x 30

Plastic PA3.5 x 30

Fig. N

Model: F52INS-SS/F52INS-PS/ F52INS-

GS/ F52INS-BS/ F52INR-PS/F52INS-BSN

Loading ...