Loading ...

Loading ...

Loading ...

28

INSTALLATION

Check the appliance is electrically safe and gas sound when you have nished.

Repositioning the range following

connection

If you need to move the range once it has been connected

then you need to unplug it and, having gripped under the

fascia panel and lifted the front of the range slightly

(Fig. 9.6), you need to check behind the range to make sure

that the gas hose is not caught.

As you progress, make sure that both the electricity cable and

gas hose always have sucient slack to allow the range to

move.

With a stability chain tted, release it as you ease the range

out. DO NOT forget to ret it when you replace the range.

When you replace the range, again check behind to make

sure that the electricity cable and gas hose are not caught or

trapped.Conversion to Another Gas

If the appliance is to be converted to another gas do the

conversion at this point. See ‘Conversion to LP Gas’.

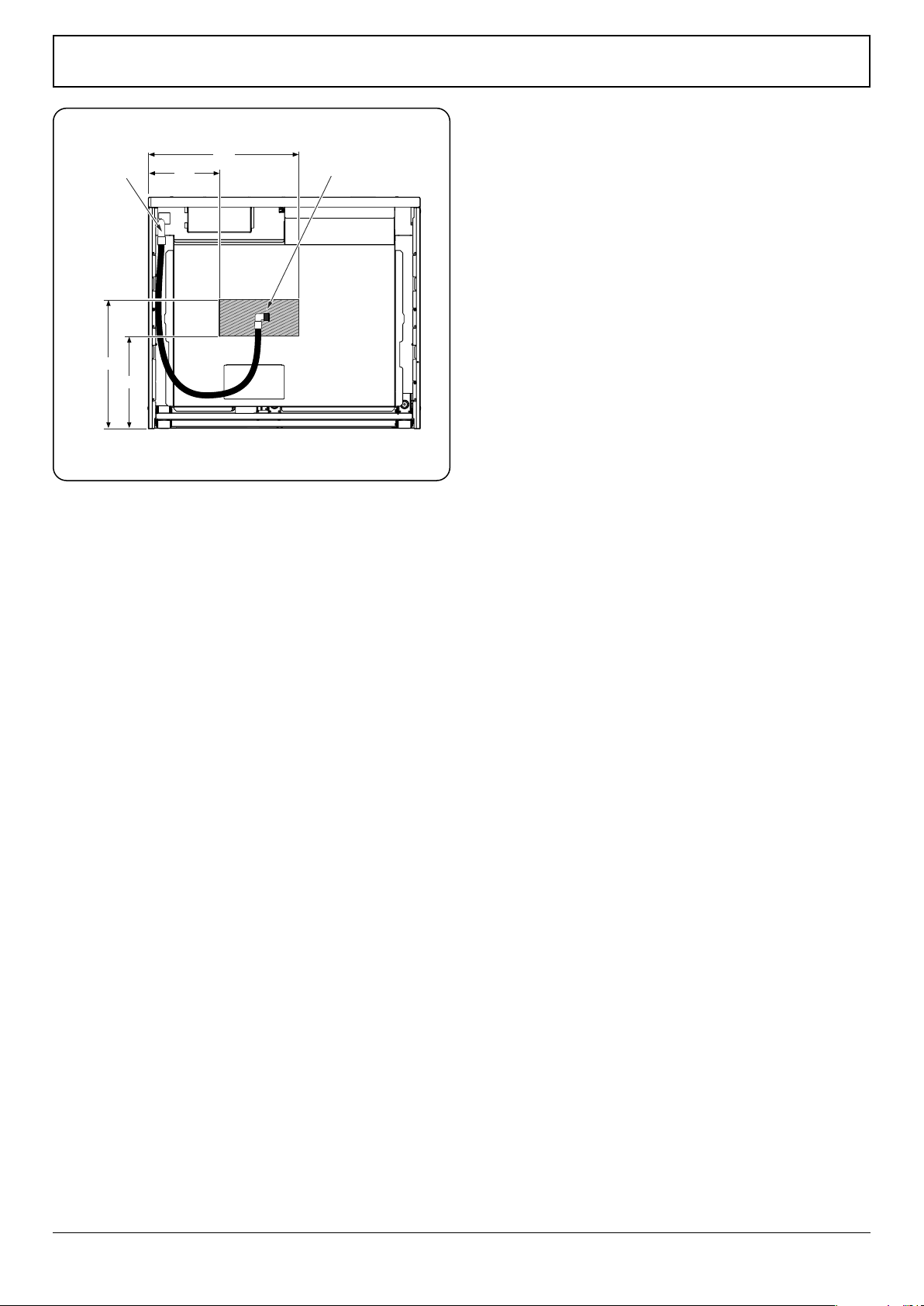

Gas Connection

This must be in accordance with the relevant standards.

The gas supply needs to terminate with a down-facing

threaded tting ½” connection. The inlet connector is located

just below the hotplate level at the rear of the range.

Because the height of the range can be adjusted and

each connection is dierent, it is dicult to give precise

dimensions. Ideally the hose supply connection should be

within the shaded area ‘A’ (Fig. 9.12).

Means of isolation must be provided at the supply point by

either an approved quick-connect device or a Type 1 manual

shut-o valve.

The hose should be tted so that both inlet and outlet

connections are vertical so that the hose hangs downwards in

a ‘U’ shape.

A exible connection is supplied with the range. If it is

necessary to use another hose it must be to AS 1869 class B

and be suitable for your gas type.

If in doubt contact your supplier. Screw connect the threaded

end of the hose into the gas inlet.

After completing the gas connection, check the range is gas

sound with a pressure test. When checking for gas leakes do

not use washing up liquid – this can corrode. Use a product

specically manufactured for leak detection.

Natural Gas

The gas pressure regulator is preset to give a nominal

pressure of 1 kPa on Natural Gas. Connect to the Rp ½ inlet on

the underside of the pressure regulator.

Propane

This range is supplied ready for use on natural gas. A

conversion kit for Propane as is supplied with the range – see

the ‘Conversion to Propane Gas’ section.

675

A

315

Gas inlet

470

350

All dimensions in millimetres

Fig. 9.12

Loading ...

Loading ...

Loading ...