Loading ...

Loading ...

Loading ...

26

INSTALLATION

Check the appliance is electrically safe and gas sound when you have nished.

*See note

*See note

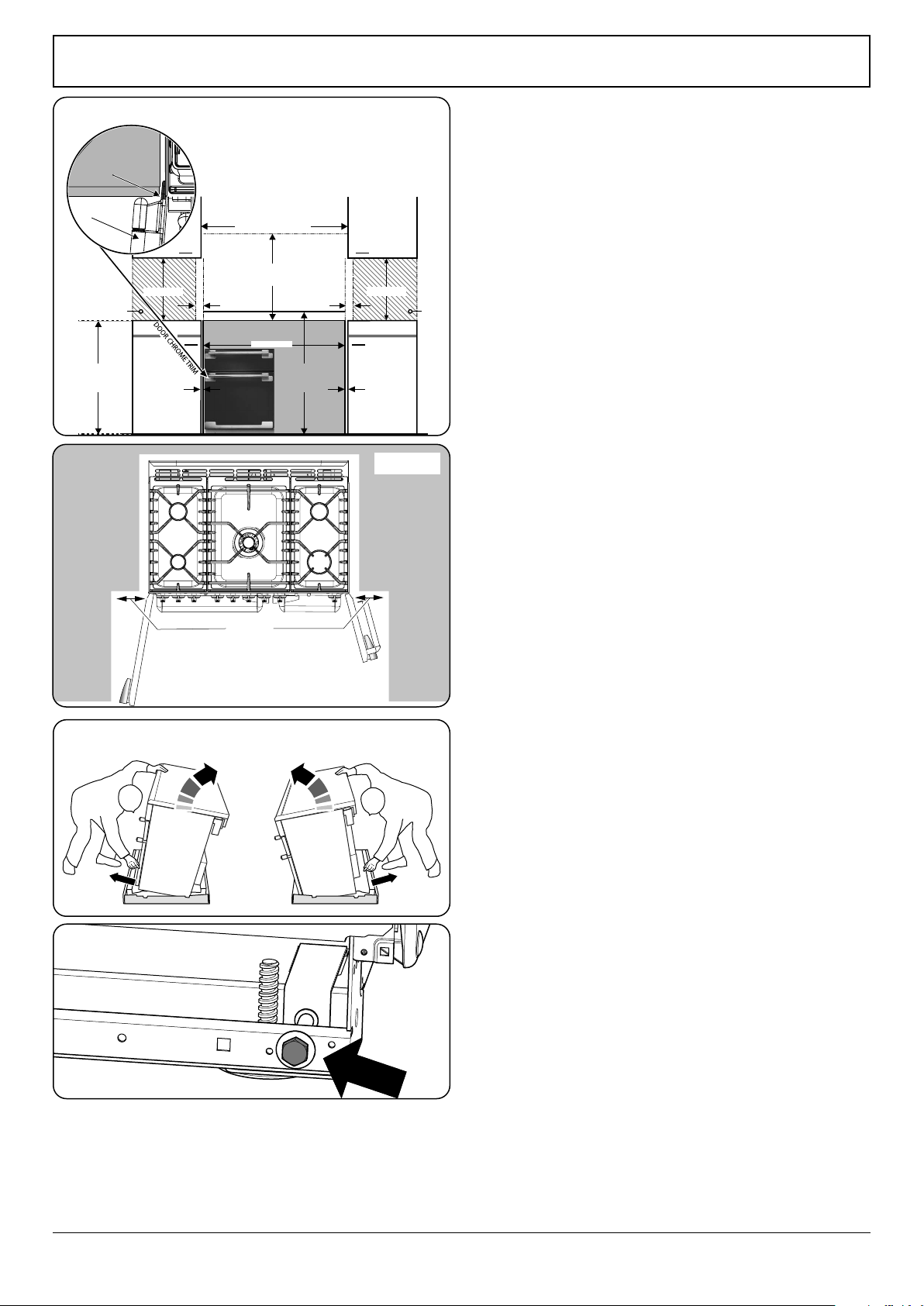

Height to Flue Trim

925 mm min

950 mm max

Height to Hotplate

910 mm min

935 mm max

650 mm min

410 mm min

410 mm min

Wall

Wall

910 mm min

check cookerhood instructions for actual dimensions

900 mm

75 mm min 75 mm min

WORKTOP

DOOR CHROME TRIM

DOOR HANDLE

130 mm

*Note

5mm gap if the appliance is 30mm in front of

the kitchen cabinets

9mm gap if the appliance is to be ush tted

between kitchen cabinets

Fig. 9.4

Fig. 9.5

When Fitting Between Kitchen

Cabinets

We recommend that you either:

A. Fit the range so that any cabinet doors are at least

30 mm behind the range door fronts. Note that this may

require an inll piece behind the range.

We recommend a gap of 910 mm between units to

allow for moving the range (Fig. 9.4). Do not box the

range in – it must be possible to move the range in and

out for cleaning and servicing.

B. Leave a gap of at least 9 mm on either side of the range

(a 918 mm gap between units) (Fig. 9.4 and Fig. 9.5).

The range should be positioned centrally.

We also recommend that you do not nal x any adjacent

cabinets until the range is installed. Decorative mouldings or

handles on cabinet doors and fronts may interfere with the

opening of the oven doors.

Moving the range

n

On no account try and move the range while it is

plugged into the electricity supply.

n

The range is very heavy, so take extra care.

We recommend that two people manoeuvre the range. Make

sure that the oor covering is rmly xed, or removed, to

prevent it being disturbed when moving the range around.

To help you, there are two levelling rollers at the back, and

two screw-down levelling feet at the front.

Remove the polystyrene base pack. From the front, tilt the

range backwards and remove the front half of the polystyrene

base (Fig. 9.2).

Repeat from the back and remove the rear half of the

polystyrene base.

Lowering the two rear rollers

To adjust the height of the rear of the range, rst t a 13 mm

spanner or socket wrench onto the hexagonal adjusting

nut (Fig. 9.3). Rotate the nut – clockwise to raise – counter-

clockwise to lower.

Make 10 complete (360°) turns clockwise.

Make sure you lower BOTH REAR ROLLERS.

Fig. 9.2

Fig. 9.3

Loading ...

Loading ...

Loading ...