Loading ...

Loading ...

Loading ...

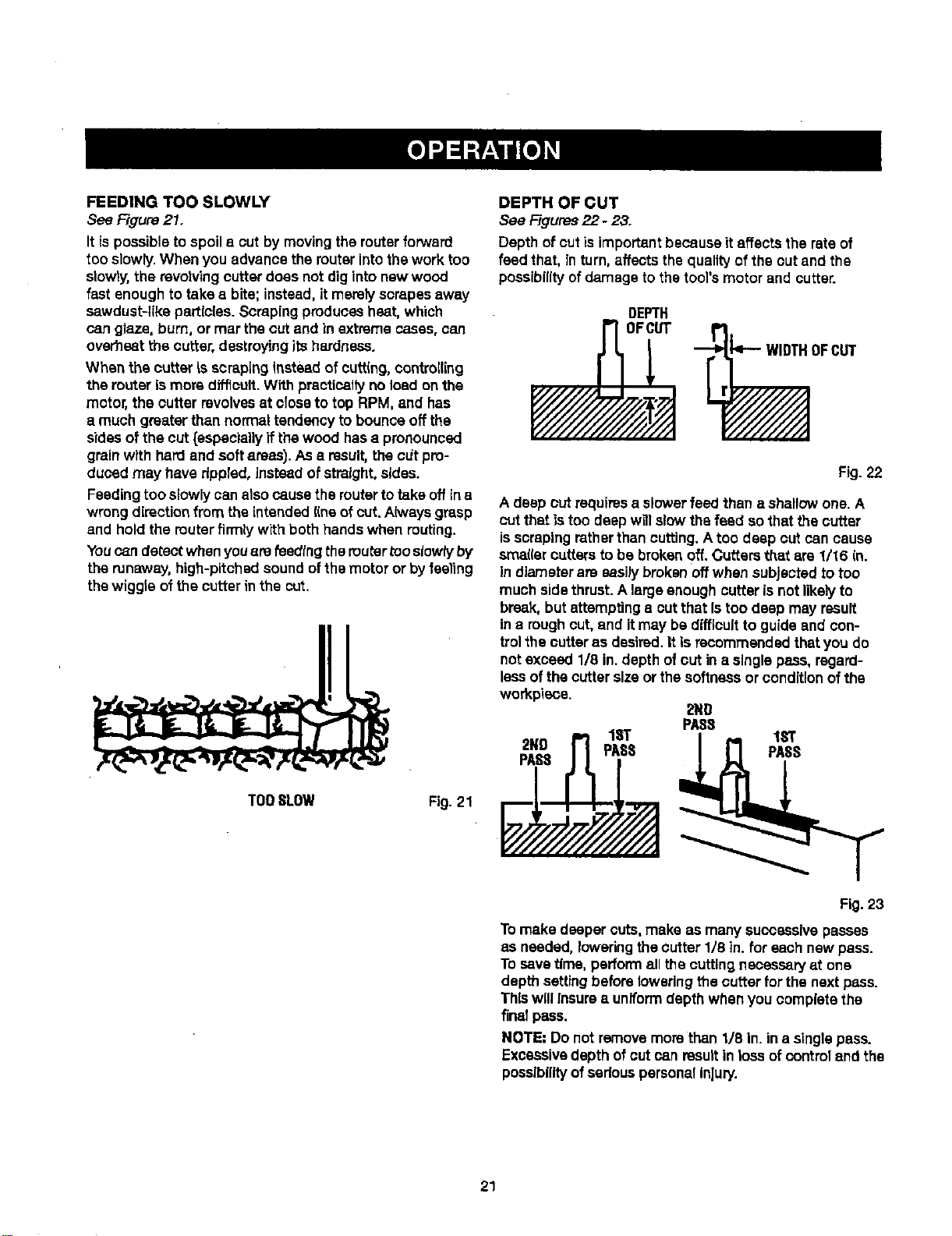

FEEDINGTOOSLOWLY

See Figure 21.

It is possibleto spoil a cut by movingthe routerforward

too slowly.When you advance the routerIntothework too

slowly,the revolvingcutter does not diginto newwood

fast enough to take a bite; instead, itmerely scrapes sway

sawdust-like particles. Scrapingproducasheat, which

can glaze, burn, or mar the cut and In extremecases, can

overheat the cutter, dastroy'mg itshardness.

When the cutter is scrapinginstead of cutting,controlling

the router is more difficult.With practically no load on the

motor,the cutter revolvesat closeto top RPM, and has

a much greaterthan normaltendency to bounce offthe

sides of the cut(especially ifthe wood hasa pronounced

grain with hardand softareas). As a result, thecut pro-

duced may have rippled,insteadof straight,sides.

Feedingtoo slowlycanalso causethe routertotake offina

wrong directionfrom the intended [(neofcut. A(waysgrasp

and hold the muter firmlywith both handswhen routing.

You candemot whenyou are feeding the router tooslowlyby

the runaway,high-pitched sound of the motor or by feeling

thewiggle of the cutter in the cut.

TOOSLOW Fig. 21

DEPTH OF CUT

,SeeFigure#22- 23.

Depth ofcut is importantbecause it affects the rate of

feed that, In turn, affects the quality of the outand the

possibilityof damage to thetool'smotor and cutter.

DEPTH

0FCUT

WIDTHOFCUT

Fig. 22

2ND

PASS

A deep out requiresa slowerfeed than a shallow one. A

cutthat is too deep willslow thefeed so that the cutter

isscraping ratherthan cutting.A too deep out can cause

sma((ercuttersto be brokenoff. Cuttersthat are 1/16 (n.

in diameterare easilybrokenoffwhen subjected totoo

much side thrust.A largeenough cutter isnot likelyto

break, but attempting a outthat Istoo deep may result

in s roughcut, and itmay be difficultto guide and con-

trolthe cutter as desired.Itis recommended thatyou do

not exceed 1/8 in.depth of cut in a singlepass, regard-

lessof the cutter size or the softness orconditionof the

workpiece.

2ND

PASS

18T

PASS

Fig. 23

To make deeper cuts, make as many successivepasses

as needed, loweringthe cutter 1/8 in. for each new pass.

Tosave time, performall the cutting necessary at one

depth settingbeforelowering t'necutter for the nextpass.

Thiswill Insurea uniformdepth when you complete the

finalpass.

NOTE; Do not removemore than 1/8 in.in a singlepass.

Excessivedepth ofcut can resultin loss of controland the

possibilityofsedous personalInjury.

21

Loading ...

Loading ...

Loading ...