Loading ...

Loading ...

Loading ...

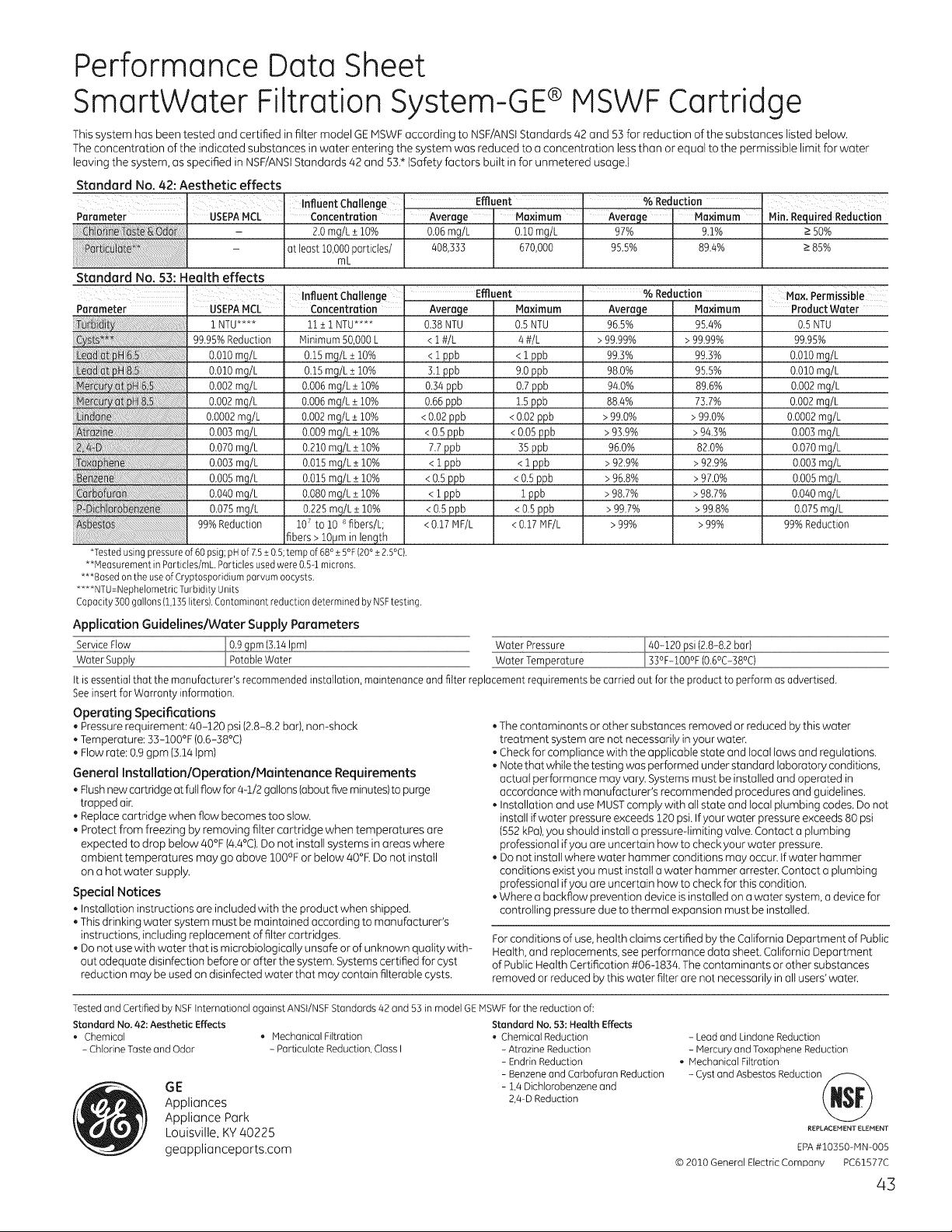

Performance Data Sheet

SmartWater Filtration System-GE ® MSWF Cartridge

This system has been tested and certified in filter model GEMSWFaccording to NSF/ANSIStandards 42 and 53 for reduction of the substances listed below.

The concentration of the indicated substances in water entering the system was reduced to a concentration less than or equal to the permissible limit for water

leaving the system, as specified in NSF/ANSIStandards 42 and 53.* (Safety factors built in for unmetered usage.}

Parameter ' USEPAMCL

Standard No. 42: Aesthetic effects

I I influentChallenge . Effluent %Reduction

Concentration Average ' Maximum ' Average Maximum Min. Required Reduction

2.0mg/L ± 10% 0.06 mg/L 0.10 mg/L 97% 9.1% > 50%

at least 10,000 particles/ 408,333 670,000 95.5% 89.4% > 85%

mL

Standard No. 53: Health effects

.... ' in"uentCha,enge.... Emuent

Parameter ' USEPAMCL Concentration Average Maximum Average Maximum

! NTU.... 11+ 1 NTU.... 0.38 NTU 0.S NTU 96.5% 95.4%

99.95% Reduction Minimum 50,000 L < 1 #/L 4 #/L > 99.99% > 99.99%

0.010 mg/L 0.15 mg/L ± 10% < I ppb < 1 ppb 99.3% 99.3%

0.010 mg/L 0.15 mg/L ± 10% 3,i ppb 9.0 ppb 98.0% 95.5%

0.002 mg/L 0.006 mg/L ± 10% 0.34 ppb 0.7 ppb 94.0% 89.6%

0.002 mg/L 0.006 mg/L ± 10% 0.66 ppb 1.5 ppb 88.4% 73.7%

0.0002 mg/L 0.002 mg/L ± 10% < 0.02 ppb < 0.02 ppb > 99.0% > 99.0%

0.003 mg/L 0.009 mg/L ± 10% <0.5 ppb < 0.05 ppb > 93.9% > 94.3%

0.070 mg/L 0210 my/L_+ 10% 7.7ppb 35 ppb 96.0% 82.0%

0.003 mg/L 0.015 mg/L _+10% < 1 ppb < 1 ppb >92.9% > 92.9%

0.005 mg/L 0.015 mg/L ± 10% < 0.S ppb < 0.5 ppb >96.8% > 97.0%

0.040 mg/L 0.080 mg/L ± 10% < 1 ppb 1 ppb > 98.7% > 98.7%

0.075 mg/L 0.225 mg/L _+10% < 0.5 ppb < 0.5 ppb > 99.7% > 99.8%

99% Reduction 107 to 10 8fibers/L; < 0.17 HF/L <0.17 MF/L > 99% >99%

fibers > 10pro in length

*Testedusing pressureof 60 psig;pH of 7.5± 0.5;temp of 680± 5%120° ±2.5°C}.

**Measurement in Particles/mL. Particles used were 0.5-1microns.

***Based onthe useof Cryptosporidium parvum oocysts.

.... NTU=NephelometricTurbidity Units

Capacity300 gallons 11,135liters). Contaminant reduction determined by NSFtesting.

% Reduction : Max, Permissible

Product Water

0.5 NTU

99.95%

0.010 mg/L

0.010 mg/L

0,002 mg/L

0,002 mg/L

0.0002 mg/L

0.003 mg/L

0.070 mg/L

0,003 mg/L

0,005 rng/L

0.040 mg/L

0.075 mg/L

99% Reduction

Application Guidelines/Water Supply Parameters

ServiceFlow Water Pressure

WaterSupply Water Temperature

It is essentialthat the manufacturer'srecommendedinstallation,maintenanceand filter replacementrequirementsbe curriedout for the product to perform asadvertised.

See insert for Warranty information.

Operating Specifications

®Pressure requirement: 40-120 psi (2.8-8.2 bur), non-shock

• Temperature: 33-100°F (0.6-38°C)

• Flow rate: 0.9 gpm (3.14 Ipm)

General Installation/Operation/Maintenance Requirements

• Flush new cartridge at full flow for 4-1/2 gallons (about five minutes} to purge

trapped air.

• Replace cartridge when flow becomes too slow.

• Protect from freezing by removing filter cartridge when temperatures ore

expected to drop below 40°F (4.4°C). Do not install systems in areas where

ambient temperatures may go above 100°F or below 40°E Do not install

on a hot water supply.

Special Notices

• Installation instructions ore included with the product when shipped.

, This drinking water system must be maintained according to manufacturer's

instructions, including replacement of filter cartridges.

• Do not use with water that is microbio)ogicaUy unsafe or of unknown quality with-

out adequate disinfection before or after the system. Systems certified for cyst

reduction may be used on disinfected water that may contain filterable cysts.

• The contaminants or other substances removed or reduced by this water

treatment system are not necessarily in your water.

, Check for compliance with the applicable state and local tows and regulations.

. Note that while the testing was performed under standard laboratory conditions,

actual performance may vary. Systems must be installed and operated in

accordance with manufacturer's recommended procedures and guidelines.

• Installation and use MUST comply with all state and local plumbing codes. Do not

install if water pressure exceeds 120 psi. If your water pressure exceeds 80 psi

(552 kPa), you should install a pressuredimiting valve. Contact a plumbing

professional if you ore uncertain how to check your water pressure.

Do not install where water hammer conditions may occur. If water hammer

conditions exist you must install a water hammer arresten Contact a plumbing

professional if you are uncertain how to check for this condition.

. Where a backflow prevention device is installed on a water system, o device for

controlling pressure due to thermal expansion must be installed.

For conditions of use, health claims certified by the California Department of Public

Health, and replacements, see performance data sheet. California Department

of Public Health Certification #06-1834. The contaminants or other substances

removed or reduced by this water filter are not necessarily in oil users' water.

Tested and Certified by NSF International against ANSI/NSF Standards 42 and 53 in model GE MSWF for the reduction of:

Standard Na. 42: Aesthetic Effects

• Chemical

- Chlorine Taste and Odor

• Mechanical Filtration

- Particulate Reduction, Class I

GE

Appliances

Appliance Park

Louisville, KY 40225

geapplianceparts.com

Standard No. 53: Health Effects

, Chemical Reduction

- Atrazine Reduction

- Endrin Reduction

- Benzene and Corbofuron Reduction

- 1,4 Dichlorobenzene and

2,4-D Reduction

- Lead and Lindane Reduction

- Mercury and Toxophene Reduction

• Mechanical Filtration

- Cyst and Asbestos Reduction_-_

REPLACEMENT ELEMENT

EPA#10350-MN-005

© 2010 General Electric ComDanv PC61577C

43

Loading ...

Loading ...

Loading ...