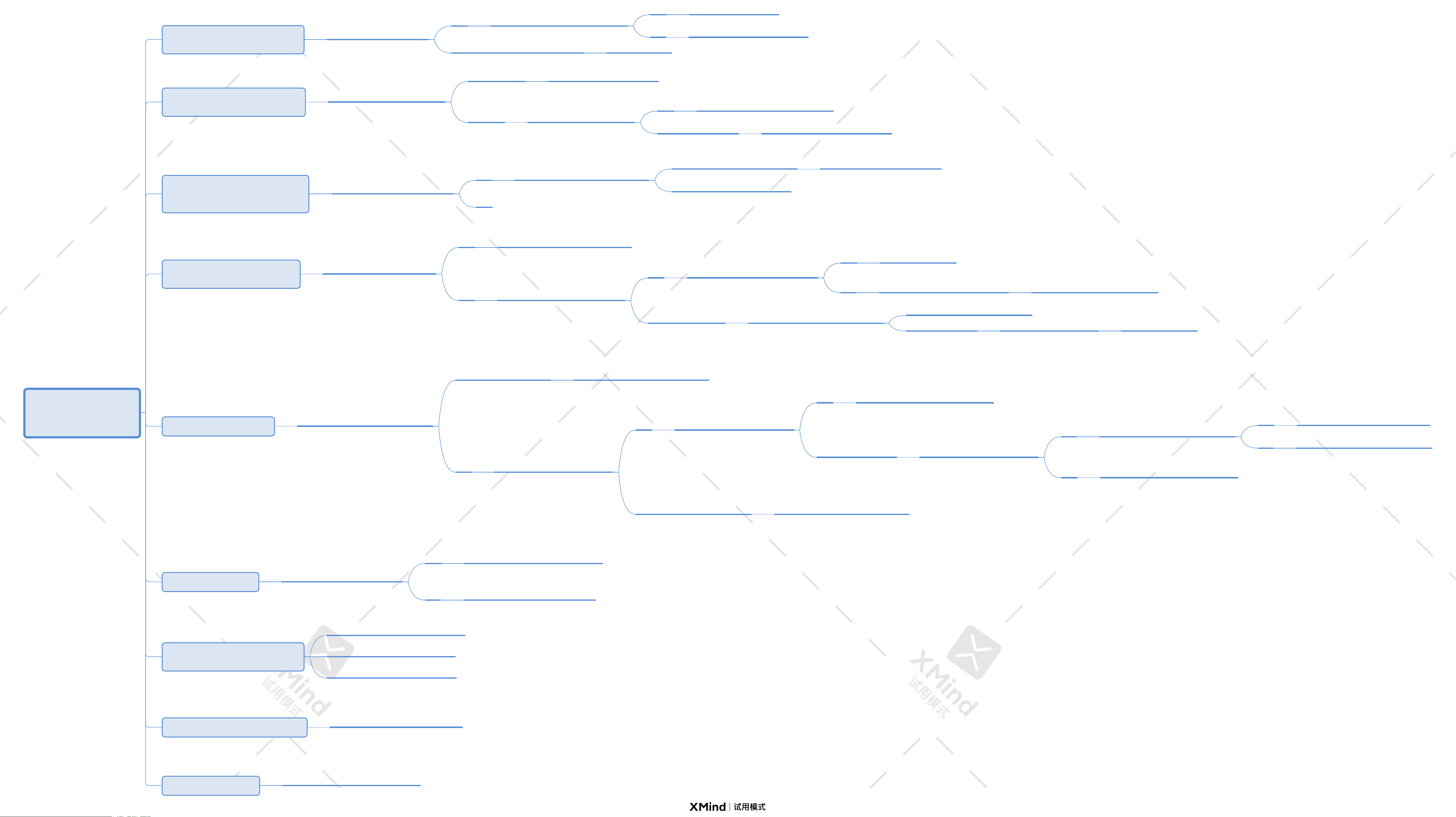

L3102 Trouble

shooting

The machine indicator light does not

light up, nor does it heat up

Check if the power cord is plugged in

Yes

With the power cord plugged in, repeatedly toggle

the switch to see if the machine recovers

Yes May be the switch is not in place

No

Machine fuse burned out, replace the whole

machine

No electricity in the socket, or not plugged in well Plug the power cord in

The machine is heated, but the green

light has not been lit

How long has the machine been heated by

electricity?

Less than 5 minutes The machine has not yet warmed up well

All the time Is it normal for the machine to laminate

Yes

The LED light is broken, we suggest the customer

to accept it and it can be used normally. Or replace

the machine

No, Smoke from the machine

Maybe the thermostat is bad, please turn off the

power immediately. Replace the machine

The machine lights up green (showing

that preheating is complete) but no

heating

Turn the machine off and on again, see if the

machine recovers

No

Use a force of no more than 60N to tap the upper

and lower covers of the machine to see if the

machine recovers

The machine is back up and starting to heat up

There are impurities between the thermostat

contacts, affecting the contact connection

The thermostat is broken, replace the whole

machine

Yes

Green light is on, heating is normal,

but not into the glue

Check if there is adhesive film stuck inside

Yes

Press and hold the ABS gear to take out the stuck

adhesive film

No

Check if the ABS gear button next to the power

cord pops up

Yes

Hold the machine up and shake whether there is

something off the noise

Yes Possibly the gears came off

No

Machine rollers swell, and the oil in contact with

the sleeve dried up, jammed and can not turn

Replace the entire machine, it is recommended

that customers do not use the power off, can

extend the service life of the machine

No, ABS button stuck inside Press the ABS key several times to see if it pops up

ABS key pops out and the rubber roller rotates

normally

ABS key does not pop up The spring on the ABS is out of gear Replace the whole machine

It got stuck when laminating

Is the over-glue material too thick (thickness more

than 1mm)

Yes, Over-glue material is too thick

Please choose the appropriate film and composite

material according to the product specifications,

too thick over-glue material will damage the

machine

No Is adhesive film a full sheet of adhesive film?

Yes

Whether to put in from the sewn end of the

adhesive film

Yes

Please press the ABS gear to remove the stuck film,

please use the appropriate size of film

Suitable size of adhesive film

Whether to put a lot of small ones on a film

together to seal the plastic

No

Whether the glue is placed diagonally or placed to

the side of the glue

Yes

Please try to put it from the middle when passing

the glue

No

The machine outlet has interference blocking glue,

replace the whole machine

Yes

This operation can easily lead to jamming, please

press the ABS gear to remove the jammed film, it is

recommended to separate the glue

No, two single-layer adhesive film together

This operation can easily lead to stuck adhesive,

please press and hold the ABS gear to remove the

stuck adhesive film. Follow up with a complete

adhesive film

Overgluing and melting

The machine just warmed up and be used to

laminate

Yes

For the first pass after preheating, it is

recommended to wait a long time after heating (3 -

5 minutes after the light turns green) to make the

roll temperature stable.

No

Please choose the appropriate gear according to

the thickness of the overgum material, overgum

material is too thin and choose high temperature

gear is easy to melt the glue

After the glue is not sticky / bubble /

edge is not attached

Remind users to choose the right gear according to

the thickness of the overgum

Remind the user not to pass anything too thick (

thickness more than 1mm)

Remind users not to use too small adhesive film

over glue

Black oil stains on the film after gluing

The glue roller is beaten with black lubricant, you

can bring out the residual lubricant by passing a

piece of paper with the size of the inlet once. The

oil can be wiped off with a paper towel

Noise from the machine

Long time standby, the machine repeatedly heated,

the machine's heating components, rollers, gears

will accelerate aging. It is recommended to power

off when not in use