Do not exceed the excessive shredded paper

standard,check whether the shredded paper is damp.

The rotating part of the machine has not been well lubricated for a long time,

so the user needs to regularly break the special oil bag to maintain the machine.

Problem solved.

Problem solved.

No

problem solved

Problem solved

It is possible to put too much paper in nominal

shredder and automatic shredder simultaneously.

After the paper is wrinkled, there is a virtual position in the touching position of the AUTO bar. The paper cannot touch the AUTO bar,and

the micro switch cannot be closed. Put the paper back in, make sure the paper does not wrinkle when shredding, and the paper can fully touch the AUTO

lever.

Restart the machine to see

whether the machine returns to

normal.

Machine circuit or motor failure, replace the whole machine.

Maybe the arm or body accidentally touched the power button and stopped the machine.

No

The paper wheel is shifted

and deviated during use.

Machine gear slip or mechanical

failure.Please replace the machine.

Problem solved

No

If the amount of shredded paper exceeds the standard specification too much, it is recommended to

control the amount of shredded paper within 6 pieces of rated shredded paper each time, which can

ensure the effect of shredded paper and prolong the life of the machine.

No

The shredding type of this machine is granular, may be paper dust, please use it normally.

No

t

Whether the machine can

accept paper properly.

to the nose or fuselage.

New machine Whether any damage is found

Yes

If the machine can work after

the temperature is controled.

Problem solved

No

Yes

No

Replace the machine

Yes

Yes

The screw is not locked properly, the AUTO lever is crushed./The front is stuck, the

AUTO lever does not rebound, loosen the screw or clean the interference front can be

restored. Problem solved.

No

PCB fault,replace the machine.

No

Yes

no

Yes

Yes

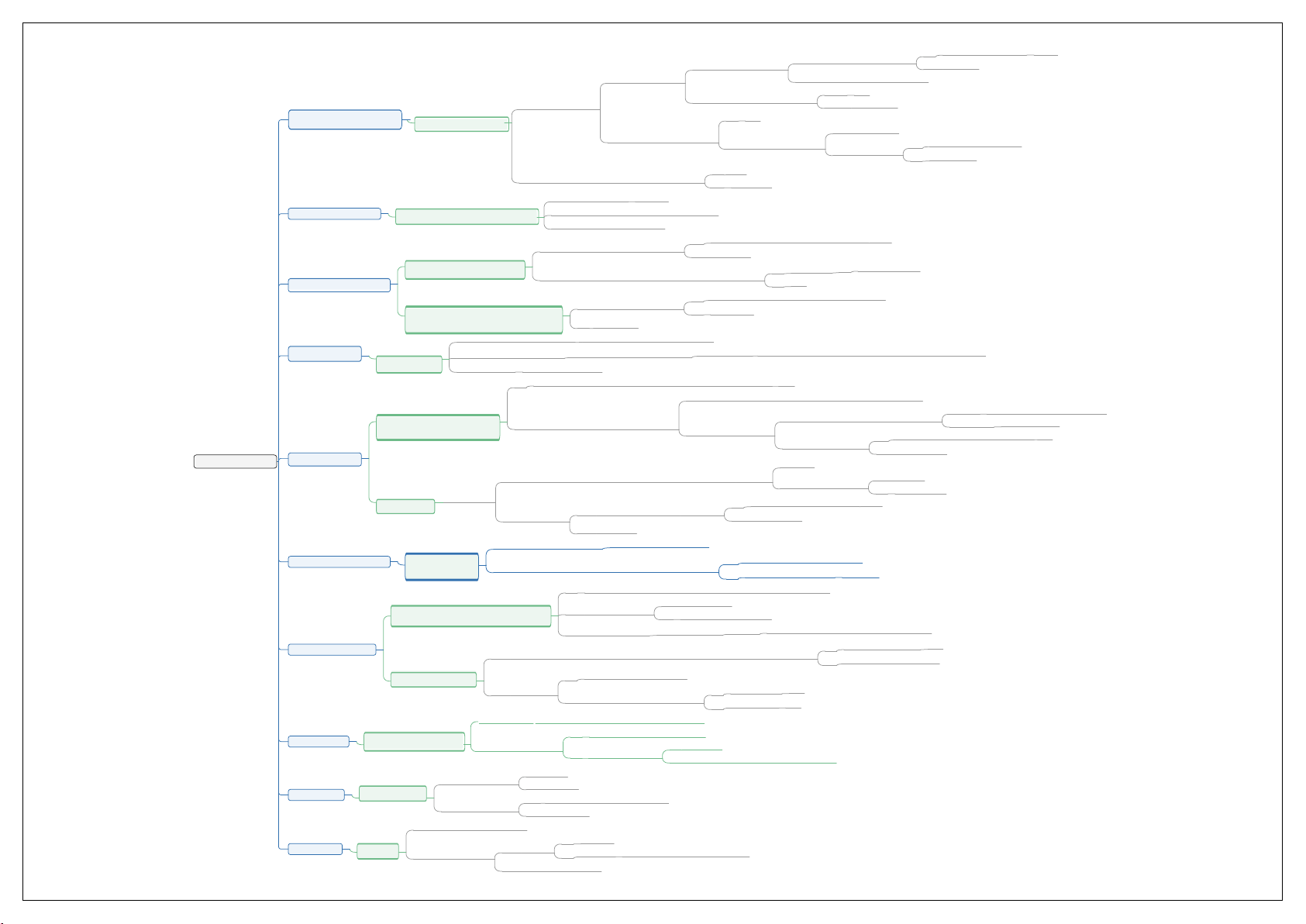

C236-B/S3109troubleshooting

list

Check whether the power socket has

power and the power cord plug is

inserted properly.

Yes C

heck whether the power

swich is on.

Yes

Check whether machine heads

or trash can are properly assembled.

Yes

Check whether the safety switch

ejectorbar in the garbage can is damaged.

No

Yes

No

No

No

Turn on the boat shift switch

Make sure the machine has power.

No

No

Yes

No

NO

There was no sound, no movement of the knife. The optical control or circuit is abnormal, replace the whole machine

Yes

No

Yes

No

Yes

The machine will roll the paper again. The cutting tool or guide paper wrapping paper is broken, replace the machine.

No

Yes

Problem solved

The blue indicator flashing(the can is full)

Replace the machine.

No

Yes

No

Yes

Yes

C236-B故障排查表.mmap - 2021/9/28 - Mindjet

Reassemble the nose and trash can and make sure

they are in place, then check the function of the machine.

Try to push the safety switch with a hard piece of paper to

make sure the machine is back to normal.

The ejector bar of the dustbin safety switch is damaged, so the safety

switch of the nose cannot be touched. Replace the dust bin.

The trash can is deformed, and the safety pole of the trash can cannot

contact the safety switch. Replace the ?trash can.

the PCB board is faulty, replace the whole

machine.

Back to

normal

Not back to

normal

Problem solved

Problem solved

Problem solved

Problem

solved

The PCB board is faulty, replace the whole

machine

Yes

Yes

The PCB board is faulty, replace the whole

machine

Whether the magnet

on the small cover

plate is loose

Reassemble the small cover magnet

The PCB board is faulty, replace the whole

machine.

Whether the small cover of the upper cover can

trigger the safety switch.

Circuit fault, replace the whole machine.

Use a piece of paper to touch the hand or automatic

paper entry, press the forward and reverse keys with your

fingers, repeat 2-3 times.

The machine gave out harsh noises

and the sound of the motor idling.

The gear is damaged, replace the whole machine.

Each time the paper is touched, the machine has the sound of

the relay clicking closed, but the tool does not move.

PCB or motor is broken, replace the whole

machine.

The machine runs continuously for a

long time or appears to block load.

Is there smoke

all the time.

Beginning to use

There is a short circuit, stop using and replace immediately

Motor failure, replace the whole

machine.

Used for a while

It only last for a few minutes. Motor heating up rapidly or temperature is too high, resulting in heat smoke insulation paint

, this is a normal phenomenon, can continue to use

The machine was broken in transit.

Machine breakdown, replacement.

Make lubricating oil or broken oil package maintenance for the machine, clean the scraps of paper on the cutting tool regularly.

Motor or gear failure, replace the whole machine.

Check whether the safety switch shrapnel in the lower

cover is hot melt adhesive stuck or the safety switch

slot in the lower cover

is covered with a front stuck and the shrapnel does not

rebound.

Check whether the two mechanical AUTO rods

in the paper inlet do not rebound or interfere

with the upper cover.

Yes

The blue indicator is on, but the paper

doesn't go in.

The machine operate automatically after

starting up or keeping after finishing work.

There is no electricity in the power socket or the power plug is not properly inserted.

After inserting the power plug and confirming that the power socket is charged,

check whether the machine is back to normal.

Check whether there is paper stuck in the paper inlet. If there is paper stuck, shredding the rated

paper from the manual paper inlet to determine whether the stuck paper is removed.

Check whether the

machine is still running.

PCB mainboard or circuit fault, please replace the machine.

After cleaning the hot melt adhesive

or the lower cover groove.

PCB circuit fault, please

replace the whole machine.

The hot melt adhesive is stuck to the safety switch shrapnel or the safety switch

groove of the lower cover is stuck to the shrapnel. It can be restored by cleaning

the hot melt adhesive or the safety switch groove of the lower cover.

PCB circuit fault, please

replace the whole machine.

Rated nominal paper used continuously for more than 5 minutes or automatic continuous shredding sheet for more than 20 minutes. If the machine is used continuously for

a long time, automatic protection will be turned on after the motor temperature control overheats. It is recommended that the machine rest for about 90 minutes before

use.

Use rated nominal paper for 3 minutes or

shred single paper for 10 minutes

It is recommended to rest the machine for 90 minutes and confirm

whether the machine can work properly after the machine has cooled

completely.

The shredding power is high. It is recommended that each shredding should comply with the nominal amount of shredding paper on the cover or

lower than the nominal amount of shredding paper, clean the scraps stuck to the cutter regularly, and use a special oil bag.

The machine is not in use, the

overheating light is on.

Overheating of the machine leads to circuit failure or

bad NTC on the motor, replace the whole machine.

The machine has overload protection function, please take out the unbroken paper, press the positive and

negative keys for 3-5 seconds, clean the paper scraps on the cutter, the machine can return to normal

Problem solved

Whether the medium contains express bags, envelopes, advertising color pages

and other accumulated thickness of more than 6 75g/m2 or paper containing

adhesive.

The paper is too thick or the paper with adhesive paper on the surface makes the machine difficult to run, which leads to too much power

and achieves the condition of blocking load. It is recommended to break the material into small pieces and not break the material with glue.

Check whether there are many scraps of

paper stuck on the cutter from the paper

outlet.

Pull out and push into the trash can or press the positive and negative buttons

for 3-5 seconds to clean, and confirm again whether it is normal after cleaning.

Try to continuously break 2 pieces of special

oil bags to see if they return to normal.

Machine back to normal

The tool is stuffed with paper, it is recommended to use the positive and negative keys

to clean the paper on the tool or increase the delay time properly.

Machine circuit or motor failure, please replace the whole machine.

Pull out the trash can and push it in again for automatic paper cleaning or press FWD button for a few seconds and then

press REV button for a few seconds for manual paper cleaning until the scraps rolled on the tool are completely cleaned.

Then check whether the problem has been resolved.

Check whether the tool tips are facing

each other at the paper outlet.

Contact customer service to replace the machine.

Machine circuit or motor failure, replace the whole machine.

Check whether the machine has

broken multiple sheets of paper.

Remove the extra paper and put the pieces of paper back in

.Check whether the machine is back to normal.

Machine circuit fault, replace the whole machine.

Overload caused by machine grasping too much paper, clean

the excess paper, rearrange the paper and put it in.Problem

solved.

Machine circuit or motor failure, replace the whole machine.

There is a lot of paper in the bucket, the bucket is full and the power

blue indicator light is flashing and accompanied by a beep sound.

The machine can be restored

after the trash can is assembled.

There is no scraps in the bucket or there is little scraps but

the machineprompts full of paper. The blue indicator does not blink,

but there is a beep prompt sound.

Rearrange the paper on the automatic

shredder board and put it in again.

The automatic feeding function of the machine will give an

alarm if the paper is not caught for three consecutive times.

Mechanical full paper,AUTO rod stuck or mechanical

full paper, micro switch shrapnel deformation.

Contact customer service to replace the nose.

Disable one of the shredders

and confirm again.

Machine back to normal.

Although this machine has nominal shredding and automatic

continuous shredding two functions, but can not shredding too much

paper simoutaneously.

Confirm whether the friction piece is not pasted in place, causing a bulge, resulting in the fall of the assembly seat between the friction piece and the

friction piece to form a difference step, the top of the step to the edge of the paper can not be broken; Remove the friction seat, make sure that the end

face of the friction sheet into the paper is lower than the upper surface of the friction seat, and paste it again.

Friction sheets are not pasted well resulting in steps,

prevent paper from being shredded, the problem solved.

The light-controlled induction light is

faulty or the circuit is abnormal.

Contact customer service to replace the nose.

Verify that the paper wheel

is properly assembled.

The outer diameter of the paper grab wheel is small,

and the size of the supporting board is not good.

Push the paper wheel to both ends of the guide rod with your fingers to

ensure the middle position of the guide rod in the paper wheel.

Wet paper makes it difficult to cut. It is recommended to reduce the number of

pieces of paper each time to ensure the effect of shredding damp papees.

Check whether it is the long strip of

paper broken out of the edge of the knife.

The tool is bad, replace the whole machine

Due to the extrusion of scraps on both sides of the tool, there are some long strips,

but the maximum scrap area is in line with the new German industrial standard 66399

, which is a normal phenomenon.

Loosen the screws of the two-lock AUTO lever twice or clean the

interference front to confirm whether the machine is back to normal.

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Smoke appeared from

the machine

Loud or unusual noise

The paper is not completely

cut or poor performance.

Halfway through the shredding,

the paper stopped moving.

The red indicator flashing

(machine overload)

No

No

No

No

No

No

No

No

No

No

No

Whether the machine is in use

and how long it has been in

continuous use

Whether the nominal rated shredded paper exceeds

6 pieces(the nominal rated shredded paper quantity

of the machine is 6 pieces 75g/m²)

No

The red indicator steady on

(machine overheating)

Automatic sheet

shredder is overloaded

Check whether a large number

of paper scraps have been

accumulated in the paper bucke

t.

Nominal crushing rating: whether the paper is wrinkled at the center

touch (corresponding to AUTO) ,or the remaining crushing paper is

tilted to one side .

Automatically shredding a single piece:

whether the paper wheel can fully

grasp the paper.

Whether there are more than 6 pieces of

paper (the rated shredding capacity of the

machine is 6 pieces 75g/m2)

How long has the machine

beenin use before it makes a

noise.

Whether there is

a burning smell.

After the machine is powered on, all the

indicators are not on, and the machine not

working.