Loading ...

Loading ...

Loading ...

CUSTOMER RESPONSIBILITIES

CHECK FOR DAMAGED/WORN PARTS

The followingdamaged/worn parts should be referred to

your Sears Service Center.

NOTE: It is normal for a small amount of oil to appear

under the saw after engine stops.Do not confusethis with

a leakino oiltank.

• On/Stop Switch - ensure on/stopswitchfunctionsprop-

erly by moving the switch to the =Stop"position and

assure that engine stops, then restartyour engine and

continue.

• Fuel Tank - discontinue use of chain saw if fuel tank

show signsof damage or leaks.

• Oil Tank- discontinue use of chainsaw ifoiltankshows

signs ofdamage or leaks.

• Chain Catcher - replace chain catcher if bent, cut, or

damaged in any way.

CLEAN UNIT AND LABELS

• Clean the unitusinga damp clothwitha milddetergent.

• Wipe off the unitwith a clean dry cloth.

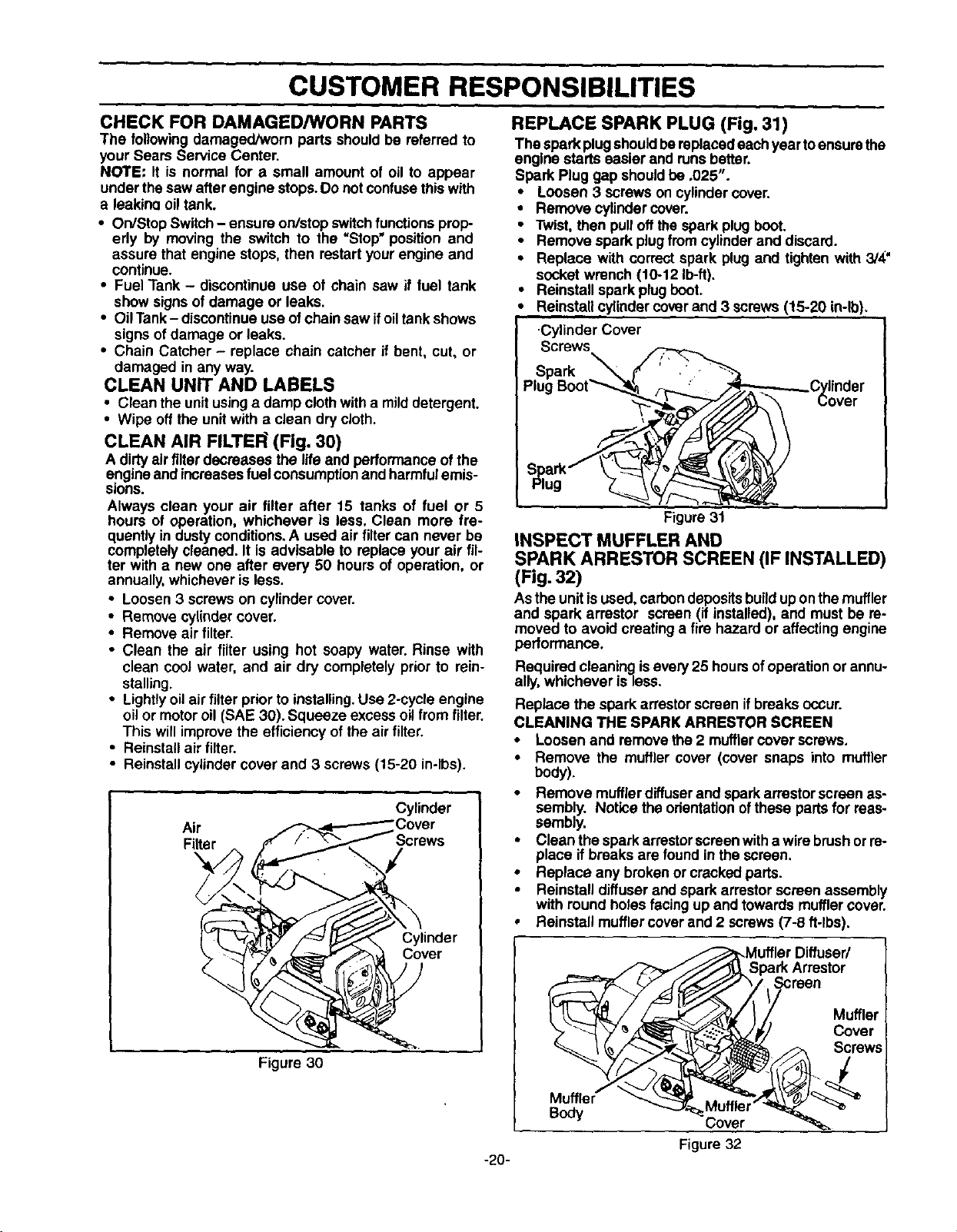

CLEAN AIR FILTE_ (Fig. 30)

A dirtyair filterdecreases the life and performance of the

engineand increasesfuelconsumptionand harmfulemis-

sions.

Always clean your air filter after 15 tanks of fuel or 5

hours of operation, whichever is less. Clean more fre-

quently in dustyconditions.A used air filtercan never be

completelycleaned. It is advisable to replace your air fil-

ter with a new one after every 50 hours of operation, or

annually,whichever is less.

• Loosen 3 screws on cylindercover.

• Remove cylinder cover.

• Remove air filter.

• Clean the air filter using hot soapy water. Rinse with

clean cool water, and air dry completely prior to rein-

stalling.

• Lightly oil air filter prior to installing. Use 2-cycle engine

oil or motor oil (SAE 30). Squeeze excess oil from filter.

This willimprove the efficiency of the air filter.

• Reinstall air filter.

• Reinstall cylinder cover and 3 screws (15-20 in-lbs).

Cylinder

Air 3over

Filter :rews

Cylinder

Cover

Figure '30

REPLACE SPARK PLUG (Fig, 31)

The spark plugshouldbereplacedeachyear toensurethe

engine starts easier and runsbetter.

Spark Plug gap shouldbe .025".

• Loosen 3 screws on cylindercover.

• Remove cylindercover.

• Twist,then pulloffthe spark plug boot.

• Remove spark plugfromcylinderand discard.

• Replace with correct spark plug and tighten with 3/4"

socket wrench (10-12 Ib-ft).

• Reinstall spark plugboot.

Reinstallcylindercover and 3 screws(15-20 in-lb).

Cylinder Cover

Screws

-20-

Figure31

INSPECT MUFFLER AND

SPARK ARRESTOR SCREEN (IF INSTALLED)

(Fig. 32)

Asthe unitisused, carbondepositsbuildupon themuffler

and spark arrestor screen (if installed),and must be re-

moved to avoid creating a fire hazard or affecting engine

performance.

Required cleaning isevery 25 hoursofoperationor annu-

ally,whichever is less.

Replace the spark arrestor screen ifbreaks occur.

CLEANING THE SPARK ARRESTOR SCREEN

• Loosen and remove the 2 mufflercover screws.

• Remove the muffler cover (cover snaps into muffler

body).

• Remove muffler diffuserand sparkarrestor screen as-

sembly. Notice the orientationofthese parts for reas-

sembly.

• Clean the sparkarrestorscreenwitha wire brushorre-

place ifbreaks are foundin the screen.

• Replace any brokenor cracked parts.

• Reinstall diffuser and spark arrestor screen assembly

with round holesfacingup and towards mufflercover.

• Reinstall mufflercover and 2 screws(7-8 ft-lbs).

Muffler

Body

_Muffler Diffuser/

_'_S Pa_ rA'_eeSt°r

G/ Z ,.u.,o,

_,.,_/j ,_/ Cover

Muffler _

Cover

Figure 32

Loading ...

Loading ...

Loading ...