Loading ...

Loading ...

Loading ...

INSTALLATION

17. Develop the well - See "Well Development and Pump

Test".

18. Before piping up a Captive Air@ Tank, be certain air pres-

sure in tank is the same as the cut-in pressure of the pres-

sure switch. For additional information, see instructions

on tank or in the tank owners manual. Complete piping

to pressure tank.

Installation with Steel Pipe

1. Read the "Do It Yourself Installation with Plastic

Pipe" section first. Information on the following items

will be found there:

Depth to water Well Depth

Drawdown Proper Pump Setting

Centering Guides Electrical Cable Splicing

Testing the Pump Pressure Tanks

2. Screw a length of galvauized pipe into discharge of pump.

3. With the pump and pipe in vertical position, tape cable

to pipe just above and below the splice connections.

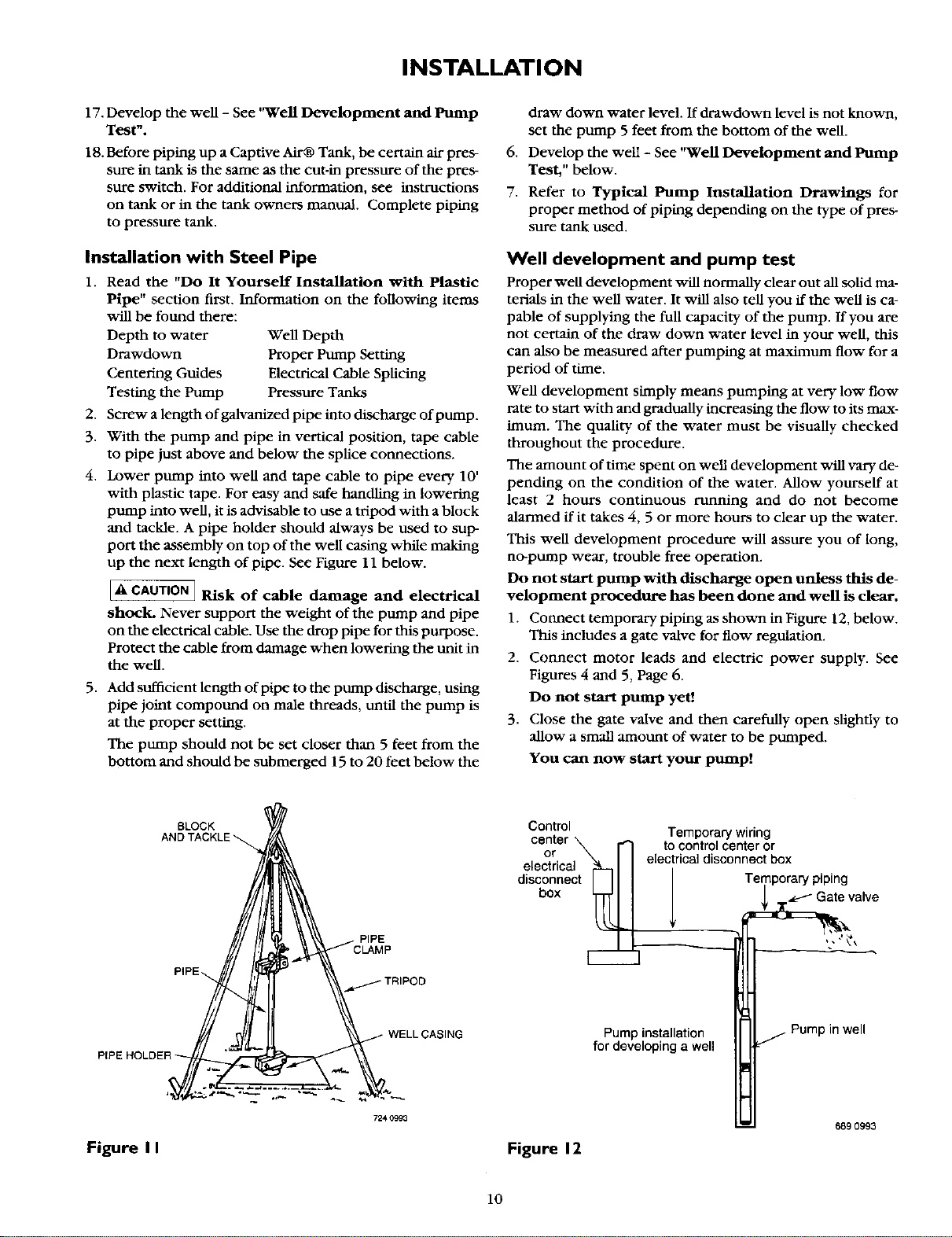

4. Lower pump into well and tape cable to pipe every 10'

with plastic tape. For easy and safe handling in lowering

pump into well, it is advisable to use a tripod with a block

and tackle. A pipe holder shotfld always be used to sup-

port the assembly on top of the well casing while making

up the next length of pipe. See Figure 11 below.

IA CAUTION] Risk of cable damage and electrical

q

shock. Never support the weight of the pump and pipe

on the electrical cable. Use the drop pipe for this purpose.

Protect the cable from damage when lowering the unit in

the well.

5. Add sufficient length of pipe to tbe pump discharge, using

pipe joint compound on male threads, until the pump is

at the proper setting.

The pump should not be set closer than 5 feet from the

bottom and should be submerged 15 to 20 feet below the

draw down water level. If drawdown level is not known,

set the pump 5 feet from the bottom of the well.

6. Develop the well - See "Well Development and Pump

Test," below.

7. Refer to Typical Pump Installation Drawings for

proper method of piping depending on the type of pres-

sure tank used.

Well development and pump test

Proper well development will normally clear out all solid ma-

terials in the well water. It will also tell you if the well is ca-

pable of supplying the full capacity of the pump. If you are

not certain of the draw down water level in your well, this

can also be measured after pumping at maximum flow for a

period of time.

Well development simply means pumping at very low flow

rate to start with and gradually increasing the flow to its max-

imum. The quality of the water must be visually checked

throughout the procedure.

The amount of time spent on well development will vary de-

pending on the condition of the water. Allow yourself at

least 2 hours continuous running and do not become

alarmed if it takes 4, 5 or more hours to clear up the water.

This well development procedure will assure you of long,

no-pump wear, trouble free operation.

Do not start pump with discharge open unless this de-

velopment procedure has been done and well is clear.

1. Connect temporarypiping as shown in Figure 12, below.

This includes a gate valve for flow regulation.

2. Connect motor leads and electric power supply. See

Figures 4 and 5, Page 6.

Do not start pump yet!

3. Close the gate valve and then carefully open slightly to

allow a small amount of water to be pumped.

You can now start your putnp!

BLOCK

PIPE

Control

or

electrical

disconnect

box

Temporary wiring

to control center or

electrical disconnect box

Temporary piping

Gate valve

m _

Pump installation

for developing a well

in well

Figure II

724 0993

Figure 12

6890993

10

Loading ...

Loading ...

Loading ...