Loading ...

Loading ...

Loading ...

f

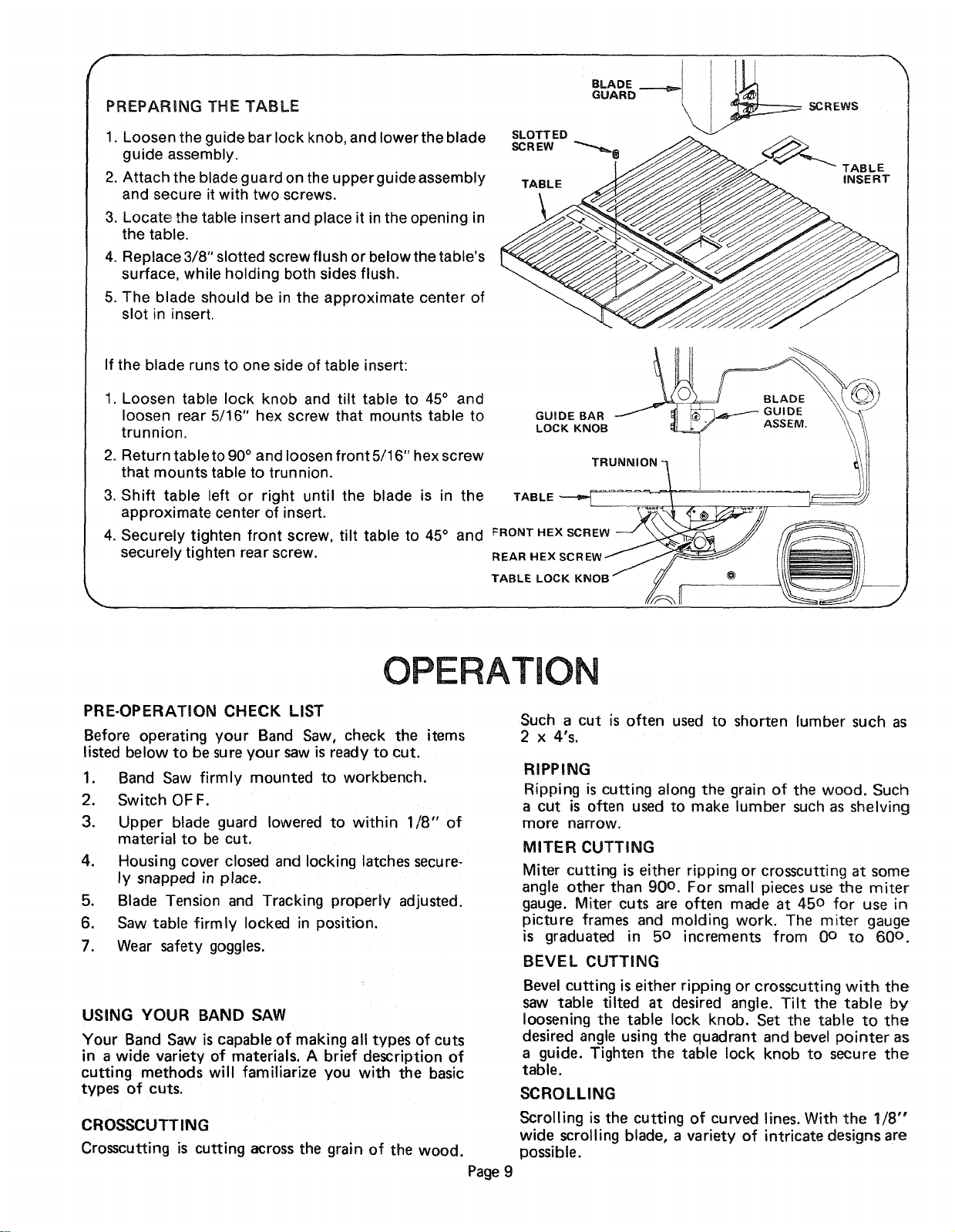

PREPARING THE TABLE

.

2.

3.

4.

5.

Loosen the guide bar lock knob, and lower the blade

guide assembly.

Attach the blade guard on the upper guide assembly

and secure it with two screws.

Locate the table insert and place it in the opening in

the table.

Replace 3/8" slotted screw flush or below the table's

surface, while holding both sides flush.

The blade should be in the approximate center of

slot in insert.

SLOTT ED

SCR EW

TABLE

SCREWS

TABLE

iNSERT

If

1.

.

3.

4.

the blade runs to one side of table insert:

Loosen table lock knob and tilt table to 45° and

loosen rear 5/16" hex screw that mounts table to

trunnion.

GUIDE BAR

LOCK KNOB

Return table to 90° and loosen front 5/16" hex screw

that mounts table to trunnion.

TRUNNION" 1

Shift table left or right until the blade is in the TABLE

approximate center of insert.

Securely tighten front screw, tilt table to 45° and FRONTREXSCREW

securely tighten rear screw. REARHEXSCR

TABLE LOCK KNOB

BLADE

GUIDE

ASSEM.

@

OPERATION

PRE-OPERATION CHECK LIST

Before operating your Band Saw, check the items

listed below to be sure your saw is ready to cut.

1. Band Saw firmly mounted to workbench.

2. Switch OF F.

3. Upper blade guard lowered to within 1/8" of

material to be cut.

4. Housing cover closed and locking latches secure-

ly snapped in place.

5. Blade Tension and Tracking properly adjusted.

6. Saw table firmly locked in position.

7. Wear safety goggles.

USING YOUR BAND SAW

Your Band Saw is capable of making all types of cuts

in a wide variety of materials. A brief description of

cutting methods will familiarize you with the basic

types of cuts.

CROSSCUTTING

Crosscutting is cutting across the grain of the wood.

Page 9

Such a cut is often used to shorten lumber such as

2 x 4's.

RiPPiNG

Ripping is cutting along the grain of the wood. Such

a cut is often used to make lumber such as shelving

more narrow,

MITER CUTTING

Miter cutting is either ripping or crosscutting at some

angle other than 90o. For small pieces use the miter

gauge. Miter cuts are often made at 45o for use in

picture frames and molding work. The miter gauge

is graduated in 50 increments from 0o to 60 o.

BEVEL CUTTING

Bevel cutting is either ripping or crosscutting with the

saw table tilted at desired angle. Tilt the table by

loosening the table lock knob. Set the table to the

desired angle using the quadrant and bevel pointer as

a guide. Tighten the table lock knob to secure the

table.

SCROLLING

Scrolling is the cutting of curved lines. With the 1/8"

wide scrolling blade, a variety of intricate designs are

possible.

Loading ...

Loading ...

Loading ...