Loading ...

Loading ...

Loading ...

METAL CUTTING

Non-ferrous metal (without iron content)can be cut

with a general purpose blade, Ferrous sheet metal

should be cut using a metal cutting blade.

SAWING TIPS

1. Whenever possible make a few test cuts in scrap

wood to be sure that the saw is properly

adjusted.

2. When making finish cuts, position the wood so

that the finished side is up. This will prevent the

finished surface from splintering.

3. Feed wood directly into the saw teeth. Don't

side load the saw blade. This is particularly

important when scrolling.

4. If you are cutting a warped board, position it

with the concave side DOWN.

5. Never force the wood into the blade. Let the

saw do the work.

6. When cutting very small pieces, use a stick to

push the wood into the blade.

7, Do not pull material being cut, backward, to

prevent the blade from jumping OFF the rollers.

8. For maximum accuracy when using miter gauge,

"favor one side of groove in table.

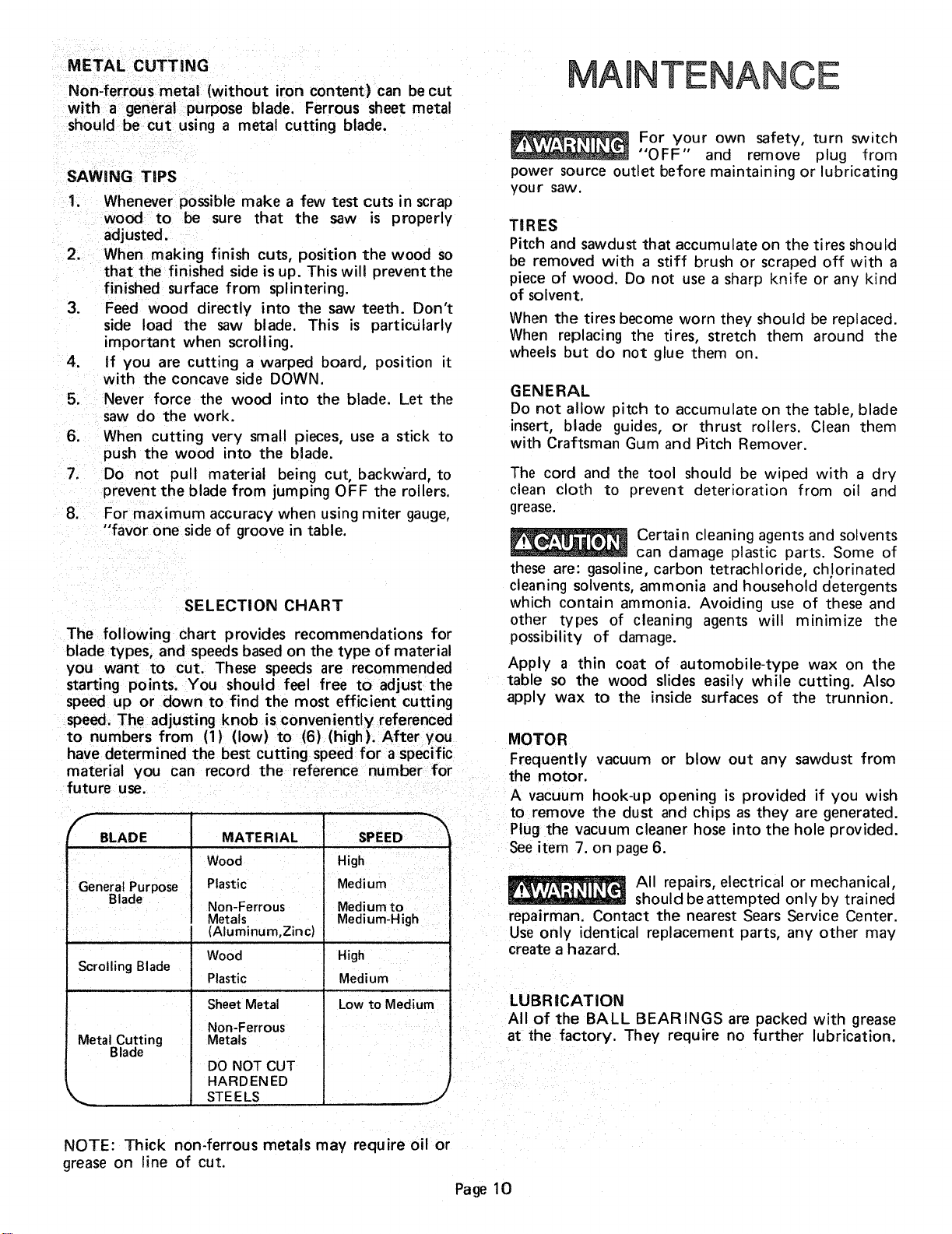

SELECTION CHART

The following chart provides recommendations for

blade types, and speeds based on the type of material

you want to cut. These speeds are recommended

starting points. You should feel free to adjust the

speed up or down to find the most efficient cutting

speed. The adjusting knob is conveniently referenced

to numbers from (1) (low) to (6) (high). After you

have determined the best cutting speed for a specific

material you can record the reference number for

future use.

F BLADE

GeneralPurpose

Blade

MATERIAL t

High

Scrolling Blade

Medium

Low to Medium

Metal Cutting

Blade

Wood

Plastic

Non-Ferrous

Metals

(Aluminum,Zinc)

Wood

Plastic

Sheet Metal

Non-Ferrous

Metals

DO NOT CUT

HARDENED

STE ELS

High

Medium

Medium to

Medium-High

J

MA TENA CE

For your own safety, turn switch

"OFF" and remove plug from

power source outlet before maintaining or lubricating

you r saw.

TIRES

Pitch and sawdust that accumulate on the tires should

be removed with a stiff brush or scraped off with a

piece of wood. Do not use a sharp knife or any kind

of solvent.

When the tires become worn they should be replaced.

When replacing the tires, stretch them around the

wheels but do not glue them on.

GENERAL

Do not allow pitch to accumulate on the table, blade

insert, blade guides, or thrust rollers. Clean them

with Craftsman Gum and Pitch Remover.

The cord and the tool should be wiped with a dry

clean cloth to prevent deterioration from oil and

grease.

Certain cleaning agents and solvents

can damage plastic parts. Some of

these are: gasoline, carbon tetrachloride, ch!orinated

cleaning solvents, ammonia and household detergents

which contain ammonia. Avoiding use of these and

other types of cleaning agents will minimize the

possibility of damage.

Apply a thin coat of automobile-type wax on the

table so the wood slides easily while cutting. Also

apply wax to the inside surfaces of the trunnion.

MOTOR

Frequently vacuum or blow out any sawdust from

the motor.

A vacuum hook-up opening is provided if you wish

to remove the dust and chips as they are generated.

Plug the vacuum cleaner hose into the hole provided.

See item 7. on page 6.

All repairs, electrical or mechanical,

should be attempted only by trained

repairman. Contact the nearest Sears Service Center.

Use only identical replacement parts, any other may

create a hazard.

LUBR ICATION

All of the BALL BEARINGS are packed with grease

at the factory. They require no further lubrication.

NOTE: Thick non-ferrous metals may require oil or

grease on line of cut.

Page 10

Loading ...

Loading ...

Loading ...