Loading ...

Loading ...

Loading ...

ADJUSTMENTS

F'"

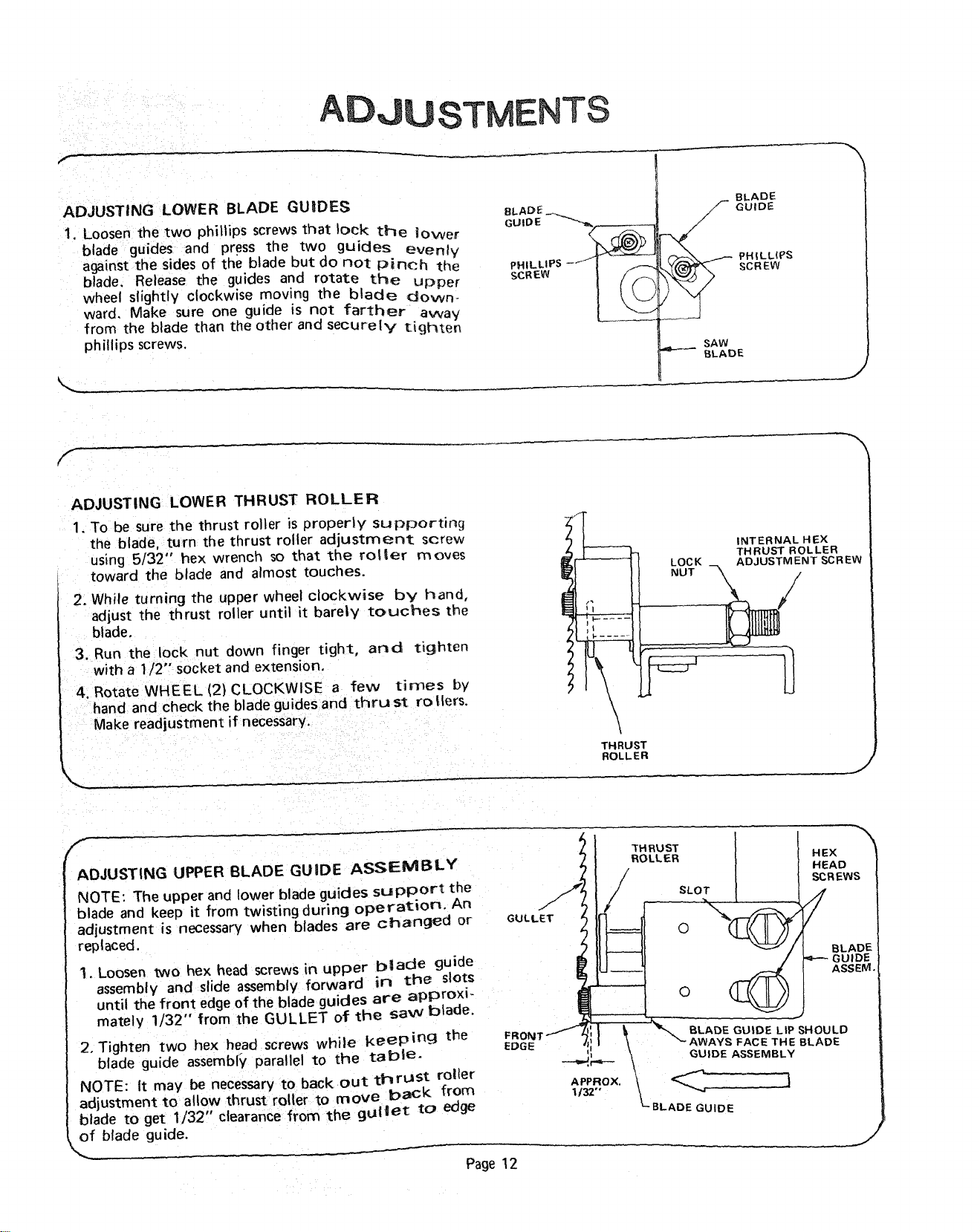

ADJUSTING LOWER BLADE GUIDES

1. Loosen the two phittips screws that lock the lower

blade guides and press the two guides evenly

against the sides of the blade but do not pinch the

blade. Release the guides and rotate the upper

wheel slightly clockwise moving the blade down-

ward. Make sure one guide is not farther away

from the blade than the other and securely tighten

phillips screws.

BLADE _.

BLADE

f- GUIDE

/

I

j__ PHILLII>S

sCREW

SAW

_--_ BLAIDE

J

F

ADJUSTING LOWER THRUST ROLLER

1. To be sure the tnrust roller is property supporting

the blade, turn the thrust roller adjustment screw

using 5/32" hex wrench so that the roller moves

toward the blade and almost touches.

2. While turning the upper wheel clockwise by hand,

adjust the thrust roller until it bare|y touches the

blade,

3. Run the lock nut down finger tight, and tighten

with a 1/2" socket and extension,

4. Rotate WHEEL (2) CLOCKWISE a few tinges by

hand and check the blade guides and thrust rollers.

Make readjustment if necessary.

l

INTERNAL HEX

THRUST ROLLER

LOCK ADJUSTMENT SCREW

THRUST

ROLLER

J

f

ADJUSTING UPPER BLADE GUIDE ASSEMBLY

NOTE: The upper and lower blade guides support the

blade and keep it from twisting during operation. An

adjustment is necessary when blades are changed or

replaced.

1. Loosen two hex head screws in upper blade guide

assembly and slide assembly forward in the slots

until the front edge of the blade guides are approxi-

mately 1/32" from the GULLET of the saw blade.

2. Tighten two hex head screws while keeping the

blade guide assemble/ parallel to the table.

NOTE: It may be necessary to back out thrust roller

adjustment to allow thrust roller to move back from

blade to get 1/32" clearance from the gullet to edge

of blade guide.

HEX

HEAD

R EWS

BLADE

e---- GUIDE

ASSEM.

SHOULD

BLADE

Page 12

Loading ...

Loading ...

Loading ...