Loading ...

Loading ...

Loading ...

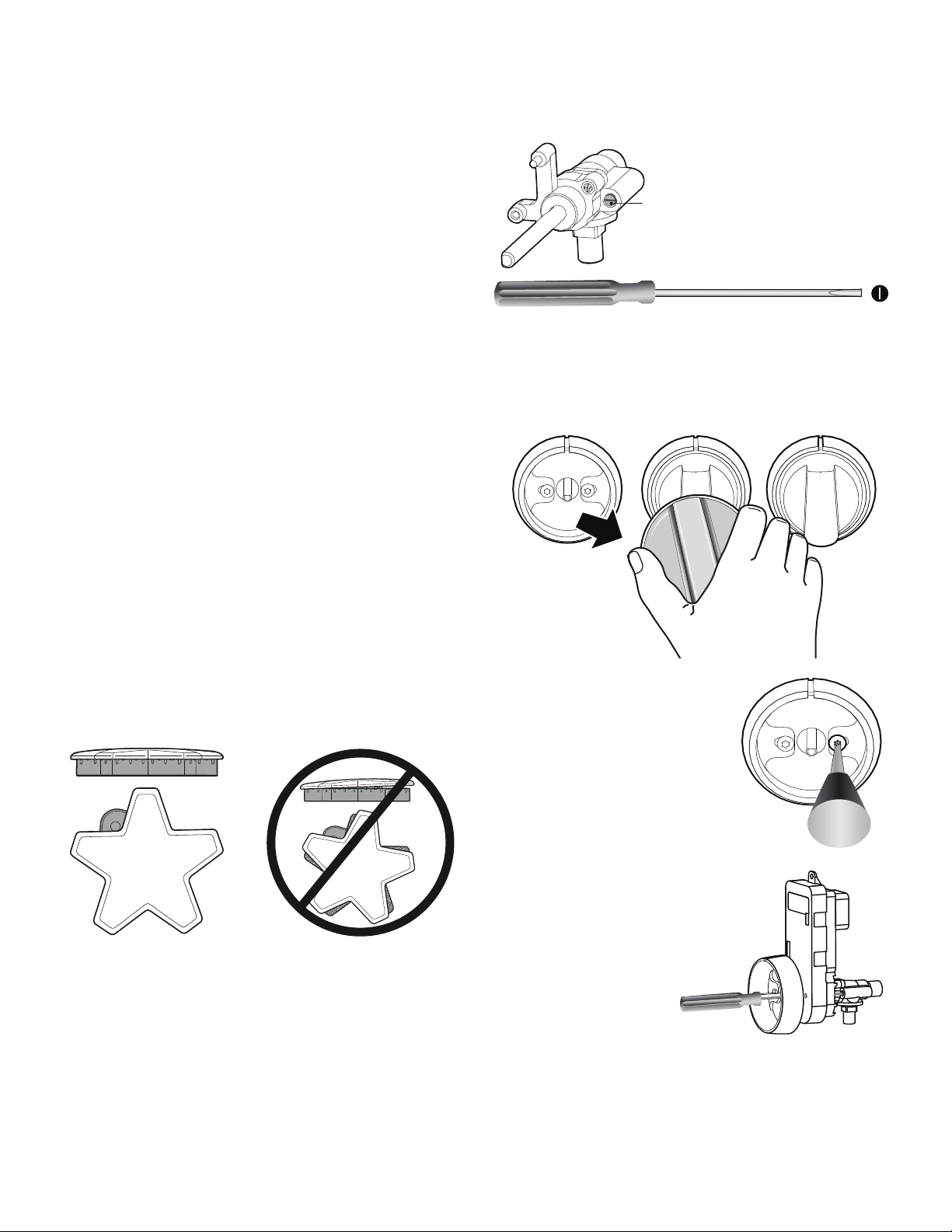

Page. 16

5. Adjust the burner’s control valve to LO to see that the

flame continues to wrap around the burner. Blow out

the flame, or use a quick fan motion from a writing

tablet or piece of cardboard to extinguish the flame,

and then observe the burner’s ability to reignite and

wrap around (also called “carry-over”) the burner

within several seconds. This flame “carry-over” is

essential for proper burner ignition and re-ignition.

6. Test re-ignition of the XLO and observe the carry-over

of the small simmer flames as the XLO system cycles

the burners on and off.

• If the low flame performance is not acceptable it

may be necessary to readjust the valve screw for a

STAR

®

burner that does not have sufficient carry-

over of the low flame. Turn the valve screw very

slightly counter-clockwise until carry-over of the

flame is acceptable. (See “Setting the STAR®

burner valve screws” on page 16.)

• If the burner flame is uneven, flutters, makes

excessive noise, or lifts, some of the slots in the

burner base may be blocked with food spillage or

other debris.

• Clogged slots can be cleared using a straightened

paper clip, needle, or similar object. Hard-to-

remove, encrusted food or debris can sometimes

be removed using a steel wool pad or fine wire

brush.

• Burner flames that are “lazy”, with excessively-

long flames, can be created by an incorrectly

fitted burner cap—from which many of the outer

mantles of the individual flames will tend to

“coalesce” or blend together. Verify that the

burner cap is seated properly on its burner base.

The cap should fit reasonably flat when correctly-

positioned on the base and not rock significantly.

7. Repeat the ignition and flame test procedures for

each rangetop STAR burner.

Setting the STAR

®

burner

valve screws

To set the burner valve screws

1. Remove the knob from the valve stem by slowly

pulling knob straight out, away from the control panel.

Correct burner cap Incorrect burner cap

Star

®

Star

®

A flat-head screwdriver with an

1/8" [3.0 mm] wide, .020"

[0.50 mm] thickness tip

(included) is used to adjust the

valve screws.

2. Remove the bezel-mounting

screw located to the right of

the valve stem, using a T-20

torx screwdriver.

3. Insert included 1/8''

flat-blade

screwdriver into the

hole of the bezel

mounting screw.

Access to the valve

screws through the

clearance hole in the

spark module. You

should feel the

engagement of the

screwdriver and the

valve screw.

Loading ...

Loading ...

Loading ...