Loading ...

Loading ...

Loading ...

W415-1087 / A / 06.06.13

12

EN

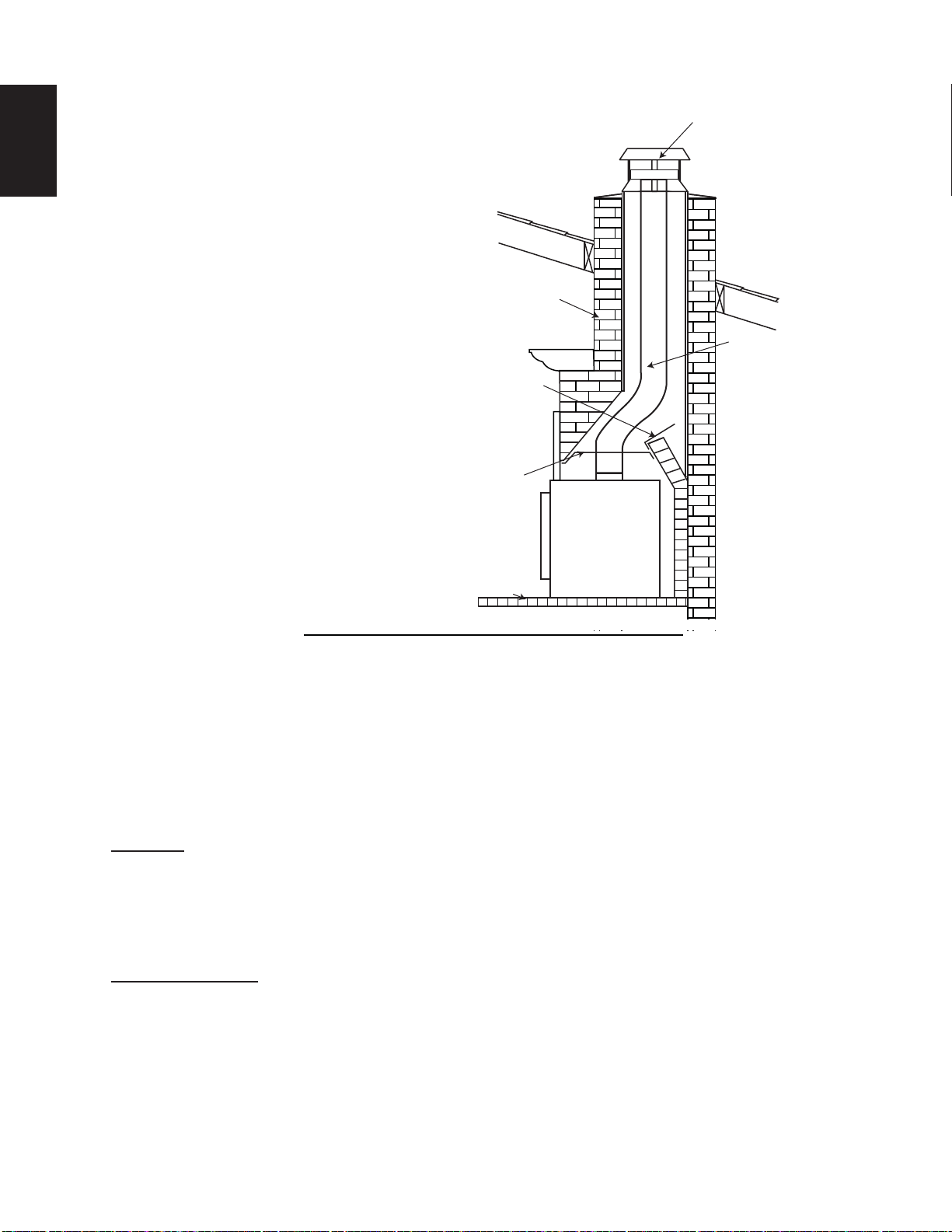

4.1 TYPICAL EXISTING MASONRY

You can install your appliance using your existing masonry chimney. To do

so, follow the guidelines below. If you are using a masonry chimney, it

is important that it be built in compliance with the specifi cations of the

Building Code in your region. It must normally be lined with fi re clay

bricks, metal or clay tiles sealed together with fi re cement. (Round

fl ues are the most effi cient).

62.2

FOLLOW MANUFACTURER’S

INSTRUCTIONS FOR

MAXIMUM LINER EXTENSION

ABOVE CHIMNEY

FLOOR

PROTECTOR

DAMPER PLATE

REMOVED OR

FASTENED IN OPEN

POSITION

SEAL WITH NON-

COMBUSTIBLE

MATERIAL

MASONRY

CHIMNEY MUST

HAVE

STRUCTURAL

INTEGRITY

LISTED

CHIMNEY

LINER

A.Remove the fi replace damper or fasten it permanently open.

* We recommend the following method of sealing off the damper area around the liner.

B.* Measure the throat of the fi replace and mark this shape on a piece of 24 gauge (0.6mm) sheet metal

(fl ue cover); cut a six-inch [6.75” (171.5mm)] hole to lie directly below the fi replace fl ue opening. Allow

two inches (50.8mm) of material for a fl ange on all sides and cut to these measurements. Bend down the

fl anges. If you have never done this before, it might be a good idea to make a cardboard pattern and test it

fi rst. Fasten this fl ue cover in position as high as possible with two masonry screws per side through the fl anges into

the fi replace.

C. Permanently seal any opening between the masonry of the fi replace and the facing masonry.

In Canada: This fi replace insert must be installed with a continuous chimney liner of 6” (152.4mm) diameter extending

from the fi replace insert to the top of the chimney. The chimney liner must conform to the Class 3 requirements of

CAN/ULC-S635, Standard for Lining Systems for Existing Masonry or Factory-Built Chimneys and Vents, or CAN/

ULC-S640, Standard for Lining Systems for New Masonry Chimneys. Attach a stainless steel liner connector or elbow

to the liner and insert onto the fl ue collar. Fasten with three screws. Secure the top of the liner to the chimney cap using

a liner support and chimney fl ashing. Cap the top of the chimney liner assembly using an approved rain cap.

In the United States: While it is not required, it is recommended that a chimney liner be installed that is continuous

from the insert to the top of the chimney, particularly when the insert is installed in a basement. For this type of

connection, use the “In Canada” installation instructions above.

If a continuous liner is not installed, a “direct fl ue connection” must be made. The direct fl ue connection requires a

non-combustible connector that extends from the insert into the chimney fl ue liner and also that the installed fl ue cover

be sealed below the entry point of the connector to prevent dilution of combustion products in the chimney fl ue with

air from inside the house. This room heater must be connected to a code-approved masonry chimney with a fl ue liner.

Cap the top of the chimney using an approved rain cap.

The following installation requirements must be observed when installing solid fuel burning inserts into factory built

fi replaces.

Loading ...

Loading ...

Loading ...