Loading ...

Loading ...

Loading ...

17

ASSEMBLY

Chute Clean-Out Tool

A chute clean-out tool is fastened to the top of the auger housing with a mounting

clip. See Figure 35. The tool is designed to clear a chute assembly of ice and

snow. This item is fastened with a cable tie at the factory. Cut the cable tie before

operating the snow blower.

WARNING

Never use your hands to clear a clogged chute assembly. Shut OFF engine

and remain behind handles until all moving parts have stopped before

using the clean-out tool to clear the chute assembly.

Chute Clean-Out Tool

Figure 35

Tire Pressure (If Applicable)

WARNING

Under any circumstance do not exceed manufacturer’s recommended psi.

Equal tire pressure should be maintained at all times. Excessive pressure

when seating beads may cause tire/rim assembly to burst with force

sufficient to cause serious injury. Refer to sidewall of tire for recommended

pressure.

The tires are over-inflated for shipping purposes. Check the tire pressure before

operating the snow blower. Refer to the tire side wall for tire manufacturer’s

recommended psi and deflate (or inflate) the tires as necessary.

NOTE: Equal tire pressure is to be maintained at all times for performance purposes.

Adjustments

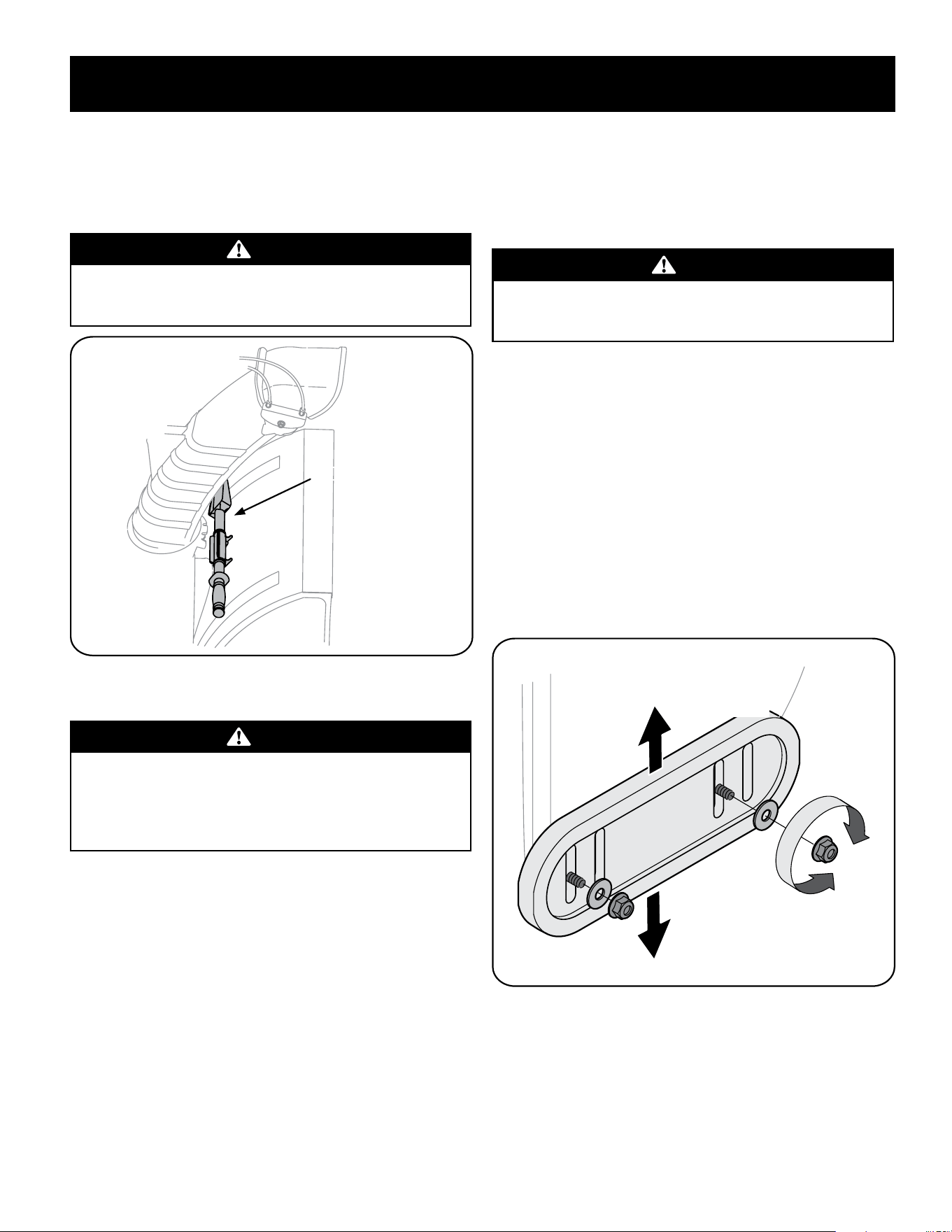

Skid Shoes

The snow blower skid shoes are adjusted at the factory to be approx 1/8” below

the bottom surface of the shave plate. Adjust them downward, if desired, prior to

operating the snow blower.

CAUTION

It is not recommended that you operate this snow blower on gravel as

it can easily pick up and throw loose gravel, causing personal injury or

damage to the snow blower and surrounding property.

• For close snow removal on a smooth surface, raise skid shoes higher on the

auger housing. See Figure 36.

• Use a middle or lower position when the area to be cleared is uneven, such as

a gravel driveway.

NOTE: If you choose to operate the snow blower on a gravel surface, keep the

skid shoes in position for maximum clearance between the ground and the

shave plate.

To adjust the skid shoes:

1. Loosen the four hex nuts (two on each side), flat washers, and carriage bolts.

Move skid shoes to desired position. See Figure 36.

2. Make certain the entire bottom surface of skid shoe is against the ground to

avoid uneven wear on the skid shoes.

3. Retighten nuts, washers, and bolts securely.

Smooth Surface

Uneven Surface

Figure 36

NOTE: The skid shoes on your unit may look slightly different (and have different

hardware) than ones shown in Figure 36.

Loading ...

Loading ...

Loading ...