Loading ...

Loading ...

Loading ...

Check SiUS121827E

238 Part 6 Service Diagnosis

8.8 Inverter Analyzer Check

Check No.15 Characteristics

Inverter analyzer: RSUK0917C

If an abnormal stop occurs due to compressor startup failure or overcurrent output when using an

inverter unit, it is difficult to judge whether the stop is caused by the compressor failure or some

other failure (main PCB, power module, etc.). The inverter analyzer makes it possible to judge the

cause of trouble easily and securely. Connect an inverter analyzer as a quasi-compressor instead

of compressor and check the output of the inverter.

Operation Method

Step 1

Be sure to turn the power off.

Step 2

Install an inverter analyzer instead of a compressor.

Note:

Make sure the charged voltage of the built-in smoothing electrolytic capacitor drops to 10 VDC or

below before carrying out the service work.

Reference:

If the terminals of the compressor are not FASTON terminals (difficult to remove the wire on the

terminals), it is possible to connect wires available on site to the outdoor unit from output side of

PCB. Do not connect them to the compressor at the same time, otherwise it may result in incorrect

detection.

Step 3

Activate the power transistor test operation from the outdoor unit.

Press the forced cooling operation ON/OFF switch for 5 seconds.

(Refer to page 248 for the position.)

→ Power transistor test operation starts.

Diagnose method (Diagnose according to 6 LEDs lighting status.)

(

R22731

)

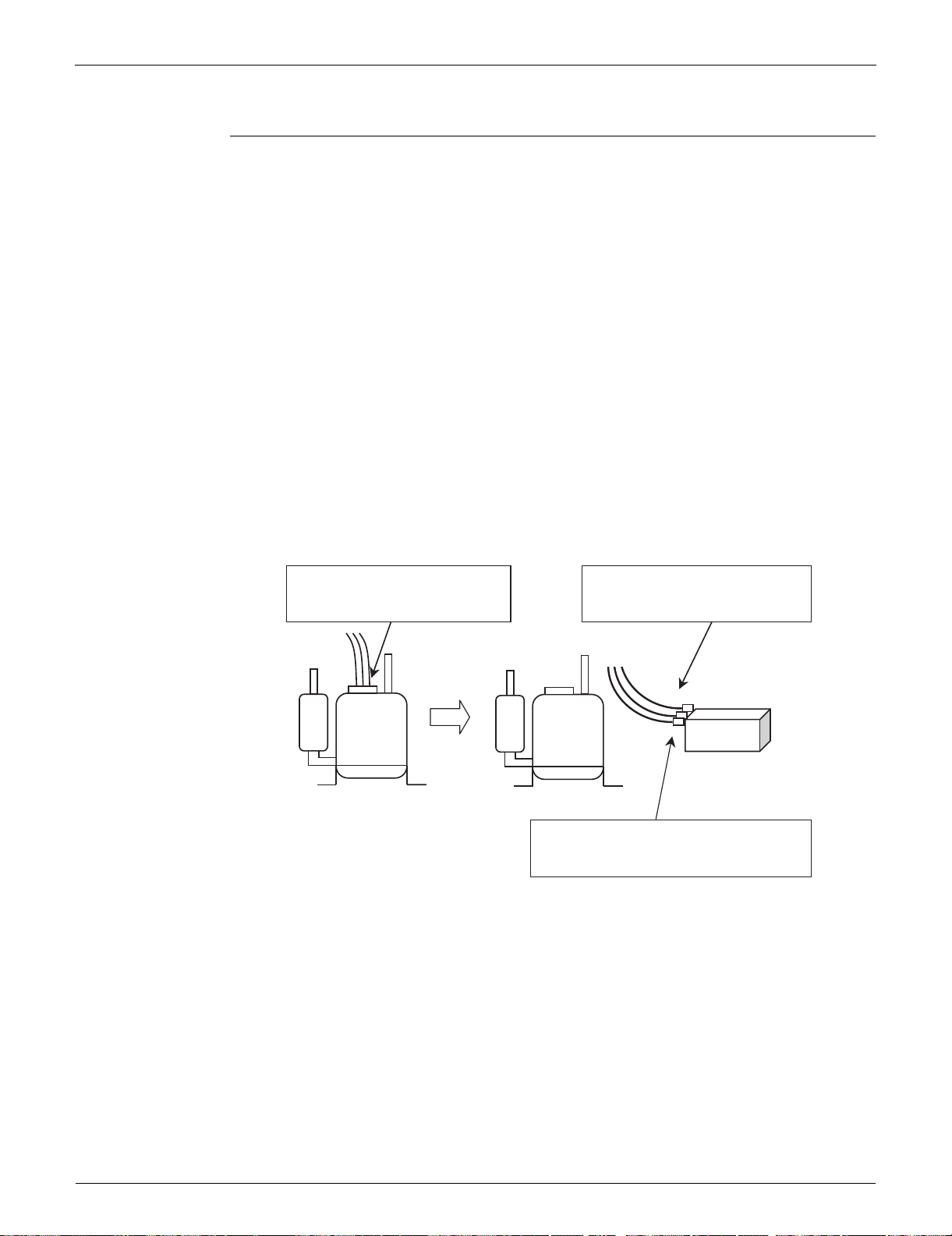

(1) Remove the terminals from

the compressor.

(2) Connect the terminals to the

terminals of the inverter

analyzer.

Compressor

Inverter analyzer

Be careful not to let the terminals (U,V,W)

touch each other. Otherwise, high voltage

is applied.

Compressor

Loading ...

Loading ...

Loading ...