Loading ...

Loading ...

Loading ...

16

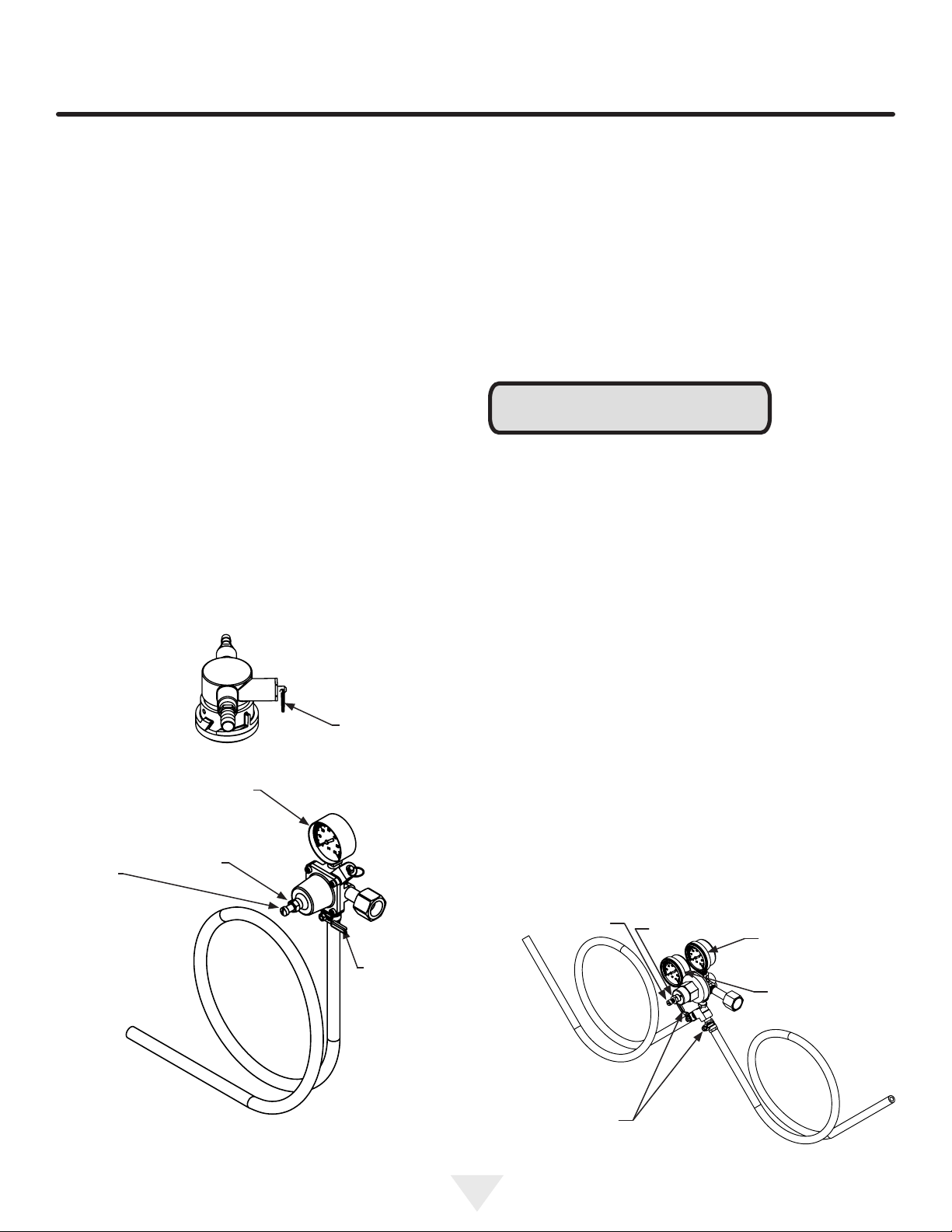

CO2 Regulator (Double Dispense Tower)

Your beer dispenser comes equipped with a 5 pound CO2

tank and a dual gauge regulator. The lower gauge should

be reading approximately 750 psi (52 bar) when the tank

is properly lled and the tank is (not in the refrigerator) at

room temperature. The tank will read less when chilled.

Use this lower gauge as an indicator of how much CO2 you

have left in the tank.

The upper gauge reads the pressure being supplied to the

beer keg. Follow the procedure below to adjust the pres-

sure to 12 - 14 psi (0.8 to 1 bar) for lager beer or 9 - 12 psi

(0.6 to 0.8 bar) for ale's.

To adjust the pressure (Upper Gauge):

1. Close the shutoff valves at the bottom of the regulator.

2. Be sure the faucet handle is closed on the tower (see

Figure 32).

3. Loosen the lock nut by turning ↶ counterclockwise us-

ing the

1

⁄2" open end wrench until loose, this will allow

adjustment of the pressure adjustment screw.

4. With the at bladed screwdriver turn the adjustment

screw ↷ clockwise to increase the pressure or ↶ coun-

terclockwise to decrease the pressure.

5. Open the shutoff valve on the bottom of the regula-

tor. The gauge reading may drop but will return very

quickly.

6. Pull the ring on the keg coupler to allow the gas to ow

momentarily.

7. Make any ne adjustments if necessary with the adjust-

ment screw.

8. Tighten the locknut with the

1

⁄2" open end wrench by

turning clockwise ↷.

CO2 Regulator (Single Dispense Tower)

Your beer dispenser comes equipped with a 5 pound CO2

tank and a single gauge regulator. The gauge reads the

pressure being supplied to the beer keg.

To adjust the pressure (Single Gauge):

1. Close the shutoff valve at the bottom of the regulator.

2. Be sure the faucet handle is closed on the tower (see

Figure 32).

3. Loosen the lock nut by turning ↶ counterclockwise us-

ing the

1

⁄2" open end wrench until loose, this will allow

adjustment of the pressure adjustment screw.

4. With the at bladed screwdriver turn the adjustment

screw ↷ clockwise to increase the pressure or ↶ coun-

terclockwise to decrease the pressure.

5. Open the shutoff valve on the bottom of the regula-

tor. The gauge reading may drop but will return very

quickly.

6. Pull the ring on the keg coupler to allow the gas to ow

momentarily.

7. Make any ne adjustments if necessary with the adjust-

ment screw.

8. Tighten the locknut with the

1

⁄2" open end wrench by

turning clockwise ↷.

Ring on keg

coupler

Figure 37 (Regulator for

Single Dispense Tower)

Figure 38 (Regulator for

Double Dispense Tower)

Figure 36

(2) shutoff

valves (closed

position shown)

Upper Gauge

Pressure Gauge

Lower Gauge

Pressure

Adjustment

Screw

Lock Nut

If the CO2 tank is inside the refrigerated compartment it

should be allowed to stabilize for a period of 12 hours at

that temperature before adjusting the pressure.

NOTE

USING YOUR BEER DISPENSER

Pressure

Adjustment Screw

Lock Nut

shutoff valve

(closed posi-

tion shown)

Loading ...

Loading ...

Loading ...