Documents: Go to download!

User Manual

- User Manual - (English)

- Technical Specifications - (English)

- Warranty - (English)

- General Safety/Installation Information

- INSTALLATION

- REPLACEMENT PARTS

- OPERATION

- MAINTENANCE

- TROUBLESHOOTING

Table of contents

OWNER’S MANUAL FOR BOOSTER PUMP

General Safety/Installation Information

- Connect this pump to a grounded circuit equipped with a ground fault circuit interrupt (GFCI) device. Make sure the outlet is within range of power cord. Do not use extension cords.

- Before installing this product, have the electrical circuit checked by an electrician to ensure proper grounding.

- Ensure the water source and piping are clear of sand, dirt, mud and scale. Debris will clog pump and void warranty.

- Failure to protect pump and piping from freezing could cause severe damage and will void the warranty.

- Make sure that the pump is accessible and that the indicator lights on the control panel are visible.

- Make sure there is adequate ventilation for the motor to ensure proper cooling

- Do not pump dry.

INSTALLATION

REPLACING OLD PUMP

Drain and remove piping from old pump. Check in the piping for rust, scale etc. Replace iF necessary.

Install the new pump making sure all pipe connections are air and water tight. Use pipe joint compound on Teflon tape on all pipe connections.

NOTE: Do not use pipe joint compound on plastic pipe/fittings or electronic control as it can degrade the plastic over time. Only use teflon tape on plastic pipe/fittings or electronic control. Make sure all piping is properly supported and the pump is on a level and supported surface.

NOTE: If the suction pipe can suck air, the pump will not be able to pull water from the source.

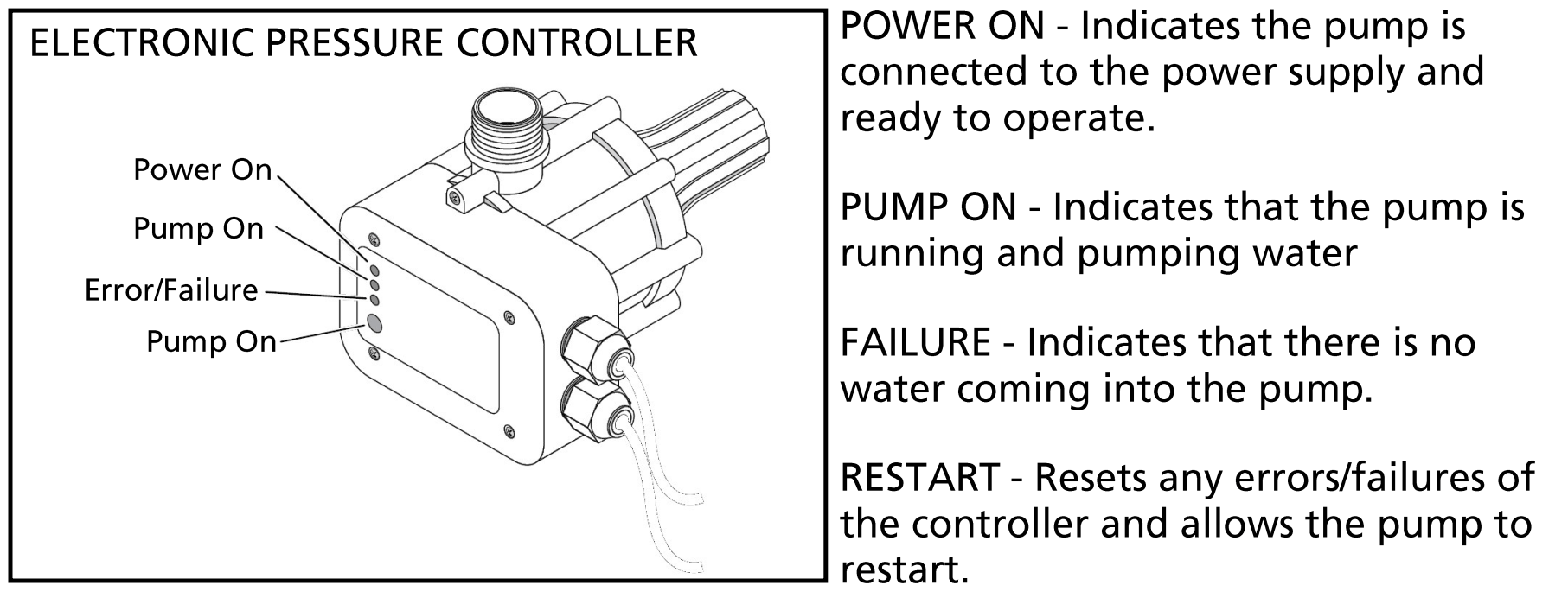

ELECTRONIC PRESSURE CONTROLLER

The automatic pressure controller protects against the following situations

- Run dry operation

- Frequent Stars caused by small pressure loss in the system

- Pressure drop

- Overheating

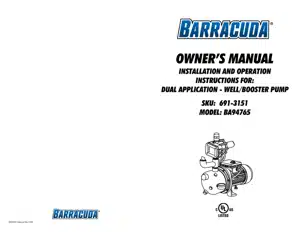

| Typical driving well point installation

|

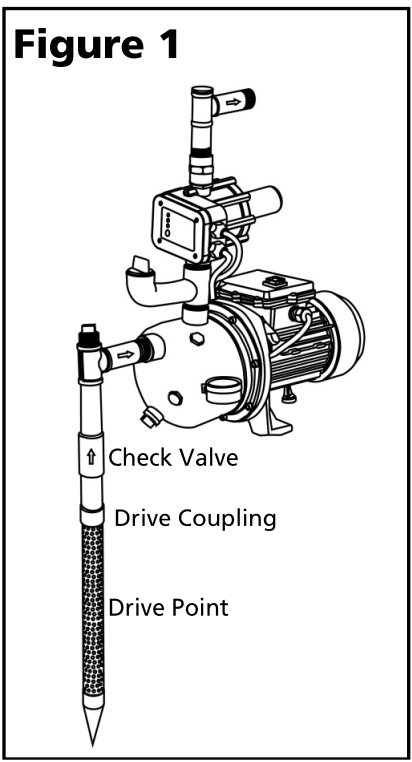

| Typical case well installation

|

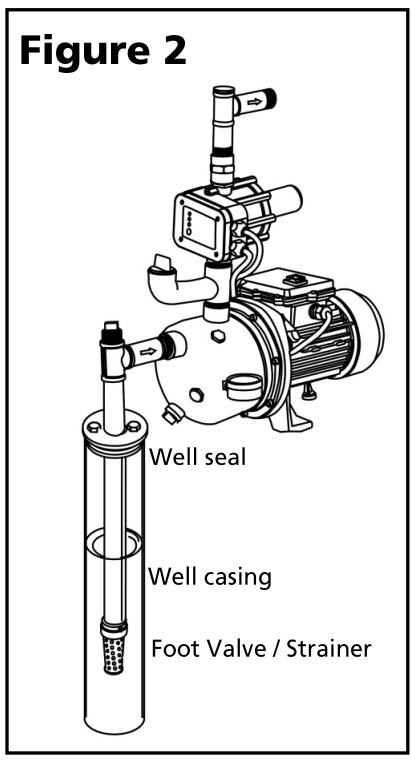

| Pressure boost installation

|

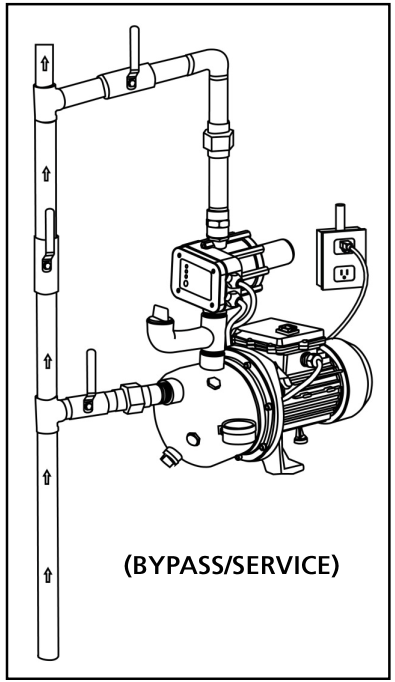

| Bypassing the pump/service

|

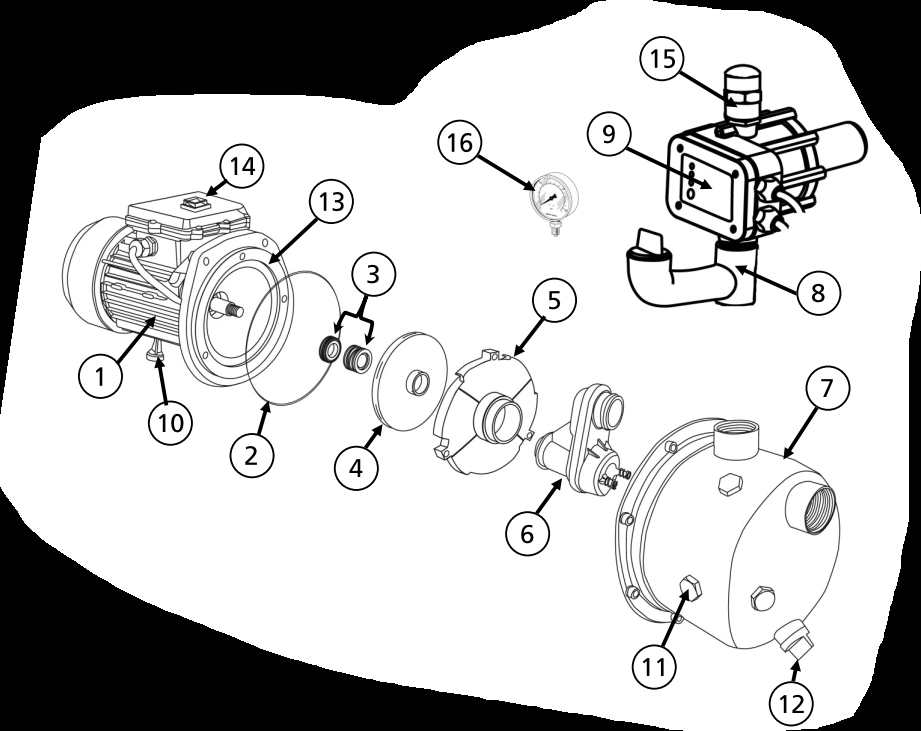

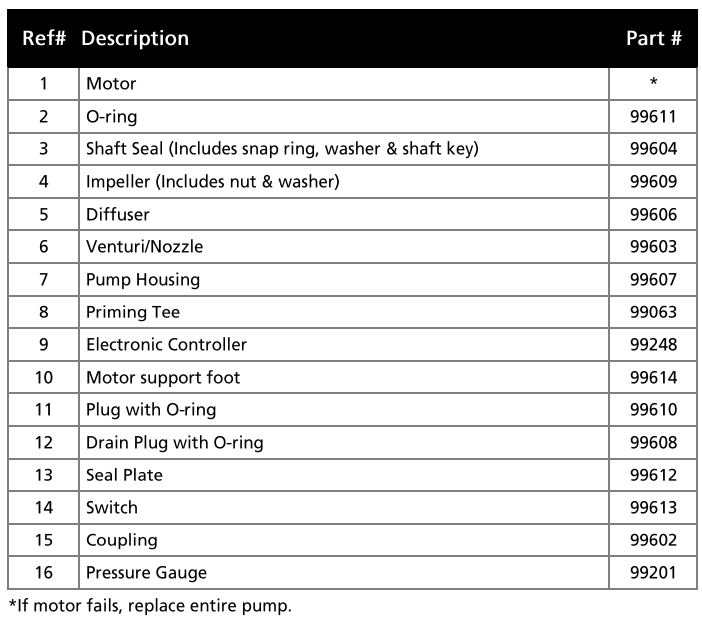

REPLACEMENT PARTS

OPERATION

PRIMING

- Remove the priming plug on the tee fitting between the pump and the electronic controller.

- Fill the housing/piping with clean water until water can be seen at the top of the fitting. Secure priming plug to the tee fitting.

ELECTRICAL CONNECTIONS

1 Plug the power cord into a grounded receptacle. The use of a GFCI is highly recommended and maybe required by local codes.

2 Once connected to the receptacle, the on-off switch and the indicator lights will illuminate on the electronic controller.

3 Turn the switch on the pump motor to the on position. The pump should turn on and start to pump water

NOTE: on initial startup after priming, it may take 10 to 30 seconds depending on amount of air in the piping for water to stop flowing. After initial start up/priming the pump will deliver water immediately after it's turned on. If the pump does not start, press the restart button on the electronic controller. Open a faucet or valve to bleed any air that may be trapped in the piping

4 The pump should shut off approximately 10 seconds after the valve/faucet etc is shut off/closed. It is normal to the pump to run for this amount of time after water flow stops. This delay prevents the pump from rapid cycling when faucets are being turned on and off quickly.

MAINTENANCE

1 Maintain adequate ventilation for the pump motor.

2 The motor bearings are permanently lubricated at the factory. Additional lubrication is not required.

3 Always protect pump and piping against freezing temperatures. If there is any danger of freezing, drain the system.

- Disconnect suction and discharge lines from pump.

- Remove plug from lower front face of pump.

- Drain a piping below the frost line or store piping indoors.

- Store pump indoors

4 The motor has no Auto reset thermal overload protector that protects the motor from damage in an overheat situation. The projector will Auto reset when motor cools. If the overload protector repeatedly trips, check the pump for possible causes (low voltage, clogged impeller, etc.).

TROUBLESHOOTING

PROBLEM | POSSIBLE CAUSES | HOW TO CORRECT |

|---|---|---|

If the pump does not start or run | Pump is not plugged in, switch/breaker is off | Plug pump in or turn on switch/ breaker |

Check for blown fuses or tripped circuit breakers or tripped GFCI outlets | Replace fuse, reset breaker, reset GFCI | |

Wire connections are loose or wired incorrectly | Tighten connections or re-wire following wiring diagram | |

Motor runs hot and thermal overload protector turns pump off | Motor is not properly vented | Make sure there is adequate room for air to circulate around the pump |

Line voltage is too low | Check voltage at receptacle, increase wire gauge if necessary. | |

If the pump runs but moves little or no water | Loss of prime | Re-prime if necessary. |

Air lock in suction line | Make sure horizontal piping between the pump and the well pitches upward towards the pump. Otherwise an airlock may form | |

Leak in suction line | Check all connections for leaks. Make sure all connections are air tight. | |

Discharge or suction pipes may be clogged or corroded | Remove clog or replace pipes if necessary | |

Vertical distance from the pump to the water is greater than 25 feet | Move pump closer to water source or shorten length of hose | |

Intake screen/foot valve is obstructed | Clean or replace if necessary | |

Foot valve or check valve is stuck in the closed position | Inspect, repair or replace if necessary | |

Foot valve or check valve is installed backwards | Make sure valve is installed in the correct direction of flow | |

Worn, damaged or clogged pump parts (Injector, impeller, diffuser, seal, etc.) | Inspect for wear, damage or clog and clean or replace if necessary | |

Foot valve is buried in sand or mud | Raise above surface bottom | |

Water level source is too low | Move suction hose | |

Pipes are frozen | Thaw pipes, heat pump house or bury pipes below frost line |

See other models: BA94715