Documents: Go to download!

User Manual

- User Manual - (English, Spanish)

- Quick Reference Guide - (English)

- Notification about built-in utility stitches, features and included accessories - (English)

- Accessories catalog - (English)

- KNOWING YOUR SEWING MACHINE

- USING YOUR SEWING MACHINE

- THE CONTROLS

- THREADING THE MACHINE

- SEWING BASICS

- SEWING BUTTONHOLES AND BUTTONS

- MAINTENANCE

- TROUBLESHOOTING

Table of contents

User manual Embroidery Machine

KNOWING YOUR SEWING MACHINE

THE MAIN PARTS

1. Bobbin winder (Page 15)

This winds the thread onto the bobbin for use as the lower thread.

2. Stitch length dial (Page 14)

Rotate the dial to control the stitch length.

3. Spool pin (Page 15, 19)

This holds the spool of thread.

4. Stitch width dial (Page 14)

Rotate the dial to control the stitch width.

5. Upper tension-control dial (Page 29)

This controls the tension of the upper thread.

6. Thread guide (Page 15, 19)

This is used when winding the thread onto the bobbin and then threading the machine.

7. Thread take-up lever (Page 20)

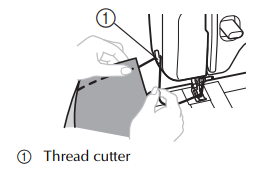

8. Thread cutter (Page 26)

Pass the threads through the thread cutter to cut them.

9. Needle threader (Page 21)

(This is only available on certain models.)

10. Quick-set bobbin (Page 18)

(This is only available on certain models.)

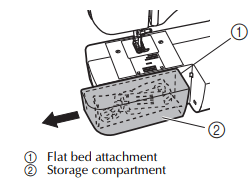

11. Flat bed attachment with accessory compartment (Page 5)

12. Presser foot (Page 8)

13. Reverse sewing lever (Page 14)

Push this lever to stitch in the reverse direction.

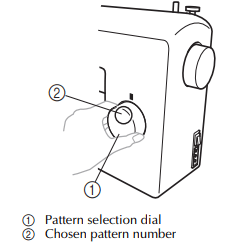

14. Pattern selection dial (Page 9)

Rotate the dial in either direction to choose the stitch you want.

15. Handwheel

Used to manually raise and lower the needle.

16. Buttonhole fine-adjustment screw (Page 38)

17. Main power and sewing light switch (Page 7)

You can turn the main power and sewing light switch on and off.

18. Foot controller jack / socket (Page 6)

Plug in the foot controller plug and connect the machine to the power supply.

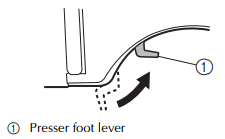

19. Presser foot lever (Page 19)

Used to raise and lower the presser foot.

20. Buttonhole lever (1-Step automatic buttonhole) (Page 36)

Lower the buttonhole lever when sewing buttonholes.

21. Foot controller (Page 7)

You can use this to control the sewing speed, and to start and stop sewing.

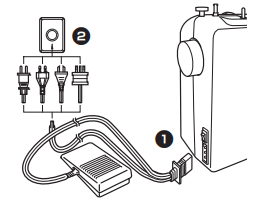

Foot Controller:

Model KD-1902 for 110-120V area

KD-1902 for 110-127V area (Brazil only)

Model KD-2902 for 220-240V area

The foot controller part code differs depending on the country or region. Contact your dealer or the nearest authorized service center.

Flat bed attachment

The accessories can be stored in a compartment inside the flat bed attachment.

1. Slide the flat bed attachment to the left to open it.

USING YOUR SEWING MACHINE

Connecting plugs

1. Connect the foot controller plug to the machine.

2. Connect the power supply plug to a wall outlet.

Note

● If a power outage occurs while the sewing machine is being operated, turn off the main power and unplug the power supply cord. When restarting the sewing machine, follow the necessary procedure to correctly operate the machine.

(For U.S.A. only)

● This appliance has a polarized plug (one blade wider than the other). To reduce the risk of electric shock, this plug is intended to fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the proper outlet. Do not modify the plug in any way

Main power and sewing light switch

This switch turns the main power and sewing light on or off.

Foot controller

When you press the foot controller down lightly, the machine will run at a low speed. When you press harder, the machine’s speed will increase. When you take your foot off the foot controller, the machine will stop

You should make sure that nothing is placed on the foot controller when the machine is not in use.

CAUTION Do not allow pieces of cloth and dust to build up on the foot controller. Doing so could cause a fire or an electric shock.

Note

(For U.S.A. only)

● Foot Controller: Model KD-1902 This foot controller can be used on the machine with product code 885-X06, 885-X08, 885-X09, 885-X26, 885-X28, 888-X06, 888-X08, 888-X09, 888-X16, 888-X18, 888-X26 and 888-X28. The product code is mentioned on the machine rating plate.

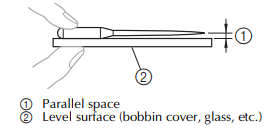

Checking the needle

The sewing needle must always be straight and sharp for smooth sewing

Checking the needle correctly

Put the flat side of the needle on a flat surface. Check the needle from the top and the sides. Dispose of any bent needles safely

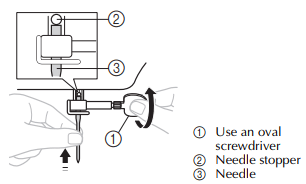

Replacing the needle

- Turn off the machine.

- Raise the needle by turning the handwheel toward you (counterclockwise) so that the mark on the wheel points up.

- Lower the presser foot lever.

4. Hold the needle with your left hand, and then use an oval screwdriver to turn the needle clamp screw counterclockwise to remove the needle

• Do not use excessive force when loosening or tightening the needle clamp screw, otherwise certain parts of the sewing machine may be damaged.

5. With the flat side of the needle toward the back of the machine, insert the needle until it touches the needle stopper. Next, tighten the needle clamp using an oval screwdriver.

Install the twin needle in the same way.

THE CONTROLS

Pattern selection dial

To choose a stitch, simply turn the pattern selection dial in either direction. The next section shows recommended stitch lengths and widths.

Stretch stitching

Raise the needle by turning the handwheel toward you (counterclockwise) so that the mark on the wheel points up.

■ 53 Stitches

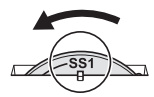

Setting the stitch length dial to “ ” changes the selected pattern to a stretch stitch.

” changes the selected pattern to a stretch stitch.

* To set the dial to “SS2”, set it to “SS1”, and then turn the dial further to the left (direction of the arrow).

■ 27/37 Stitches

Setting the stitch length dial to “ ” changes the selected pattern to a stretch stitch.

” changes the selected pattern to a stretch stitch.

THREADING THE MACHINE

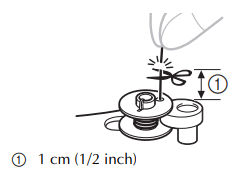

Winding the bobbin

1. Pull up the spool pin and put a spool of thread on this pin.

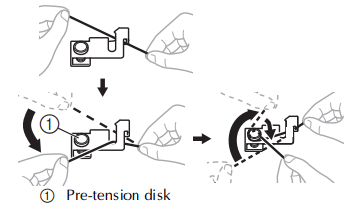

2. While holding the thread from the spool with your right hand, pass the thread toward you, in the groove on the thread guide. Then, pass the thread around the pre-tension disk and pull the thread in completely.

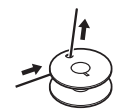

3. Pass the end of the thread through the hole on the bobbin from the inside of the bobbin.

4. Put the bobbin onto the bobbin winder shaft and slide the bobbin winder shaft to the right. Turn the bobbin clockwise, by hand, until the spring on the shaft slides into the notch of the bobbin.

• Make sure to pull out 7 to 10 cm (3-4 inches) of thread from the hole on the bobbin.

5. Turn on the machine.

6. While holding the end of the thread, gently press the foot controller to wind the thread around the bobbin a few times. Then stop the machine.

7. Trim the excess thread above the bobbin.

8. Press the foot controller to start.

9. When the bobbin seems full and begins spinning slowly, take your foot off the foot controller.

10. Cut the thread, slide the bobbin winder shaft to the left and remove the bobbin.

Note

● When the sewing machine is started or the handwheel is turned after winding the thread around the bobbin, the machine will make a clicking sound; this is not a malfunction.

● The needle bar does not move when you slide the bobbin winder shaft to the right.

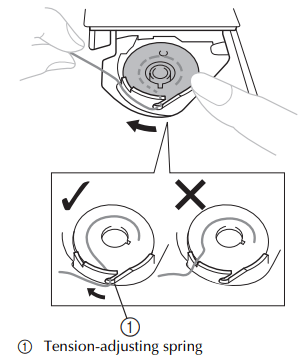

Lower threading

Install the bobbin wound with thread.

• For more details on using the quick-set bobbin, see page 18.

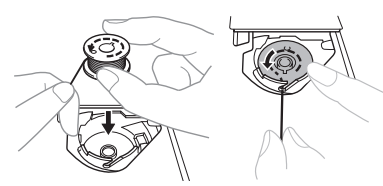

1. Prepare the bobbin wound properly before threading the lower thread.

• See page 15 for the details about bobbin winding.

2. Raise the needle by turning the handwheel toward you (counterclockwise) and raise the presser foot lever.

3. Remove the bobbin.

4. Put the bobbin in so the thread comes out in the direction shown by the arrow.

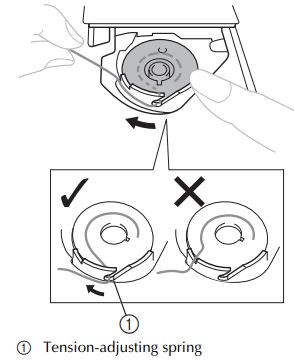

5. Hold the end of the thread, push the bobbin down with your finger, and then pass the thread through the slit, as shown.

• If the thread is not correctly inserted through the tension-adjusting spring of the bobbin case, it may cause incorrect thread tension.

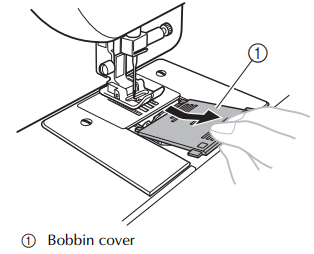

6. Replace the bobbin cover. Put the projection into the race retainer groove and push closed.

• Make sure that the end of the thread comes out from the cover toward the rear of the machine (as shown in the illustration).

• Draw up the lower thread before starting sewing. Refer to “Drawing up the lower thread” on page 22 after threading the upper thread.

Lower threading (for models equipped with a quick-set bobbin)

Install the bobbin wound with thread.

This feature is only available on certain models.

1. Follow steps 1 to 4 from “Lower threading” on page 17.

2. While lightly holding down the bobbin with your right hand as shown, guide the thread through the slit (1 and 2). Then, pull the thread toward you to cut it with the cutter (3).

• At this time, check that the bobbin easily rotates counterclockwise.

Note If the thread is not correctly inserted through the tension-adjusting spring of the bobbin case, it may cause incorrect thread tension.

3. Replace the bobbin cover. Put the projection into the race retainer groove and push closed.

• Start sewing after threading the lower and upper thread. When sewing gathers or darts, you can draw up the lower thread by hand so that some thread will be left over. Refer to the steps in “Drawing up the lower thread” (page 22)

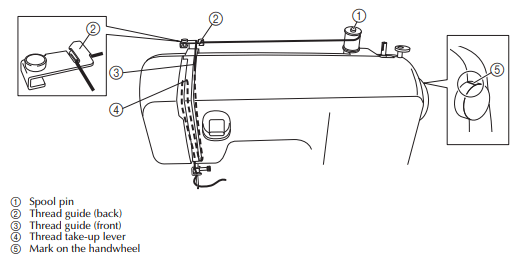

Upper threading

1. Turn off the machine.

2. Raise the presser foot lever.

3. Raise the needle by turning the handwheel toward you (counterclockwise) so that the mark on the wheel points up.

• If the needle is not correctly raised, the sewing machine can not be threaded.

4. Pull up the spool pin and put a spool of thread on this pin.

5. While holding the thread from the spool with your right hand, pass the thread toward you, in the groove on the thread guide.

• Make sure that the spring in the groove catches the thread.

6. Feed the upper thread as shown in the following illustration.

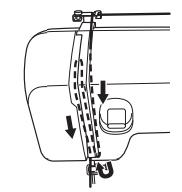

7. Make sure you guide the thread through the thread take-up lever from right to left as shown in the following illustration.

Memo If the thread take-up lever is lowered, the upper thread can not be wrapped around the thread take-up lever. Make sure you raise the needle by turning the handwheel toward you (counterclockwise) so that the mark on the wheel points up.

8. Put the thread behind the guide above the needle.

• The thread can easily be passed behind the needle bar thread guide by holding the thread in your left hand, then feeding the thread with your right hand.

9. Thread the needle from front to back leaving a thread tail of about 5 cm (2 inches).

• If your sewing machine is equipped with a needle threader, use the needle threader to thread the needle (see next section)

Note

● Make sure you raise the presser foot lever and the thread take-up lever before you feed the upper thread.

● If you incorrectly feed the thread you may cause sewing problems.

SEWING BASICS

Please read before sewing

Starting sewing

1. Turn on the machine.

2. Raise the needle by turning the handwheel toward you (counterclockwise) so that the mark on the wheel points up.

3. Turn the pattern selection dial to select a stitch (see page 9 - 13).

4. Change the presser foot (see page 8).

5. Raise the presser foot lever.

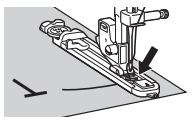

6. Place the fabric under the presser foot, pass the thread under the presser foot, and then pull out about 5 cm (2 inches) of thread toward the rear of the machine.

7. While holding the end of the thread and the fabric with your left hand, turn the handwheel toward you (counterclockwise) with your right hand to lower the needle to the starting point of the stitching

8. Lower the presser foot lever.

9. Slowly press down on the foot controller.

The machine starts sewing.

10 Take your foot off the foot controller.

The machine stops sewing.

• You can use reverse sewing for back tacking and reinforcing seams by pressing the reverse sewing lever. Refer to “Reverse sewing lever” on page 14 for the details.

11. Raise the needle by turning the handwheel toward you (counterclockwise).

12. Raise the presser foot lever.

13. Pull the fabric to the left side of the machine, and then pass the threads through the thread cutter to cut them.

Trial sewing

A trial piece of fabric should be sewn. Use a piece of fabric and thread that are the same as those used for your project, and check the thread tension and stitch length and width.

Changing the sewing direction

Stop the machine with the needle in the fabric at the point where you want to change the sewing direction, and then raise the presser foot lever. Using the needle as a pivot, turn the fabric, lower the presser foot lever, and then continue sewing.

Sewing thick fabrics

■ If the fabric does not fit under the presser foot

If the fabric does not fit easily under the presser foot, raise the presser foot lever even higher to bring the presser foot to its highest position.

Sewing thin fabrics

When sewing thin fabrics, the stitching may become misaligned or the fabric may not feed correctly. If this occurs, place thin paper or stabilizer material under the fabric and sew it together with the fabric. When you have finished sewing, tear off any excess paper.

Sewing stretch fabrics

First, baste the pieces of fabric together, and then sew without stretching the fabric.

SEWING BUTTONHOLES AND BUTTONS

Making a buttonhole (1-step automatic buttonhole)

Making a buttonhole is a simple process that provides reliable results.

With the 1-step Automatic Buttonhole Stitch pattern, a buttonhole is sewn by automatically changing the sewing direction when the buttonhole lever and buttonhole foot are used.

Note

● When sewing a stitch pattern other than for a buttonhole, do not lower, touch or move the buttonhole lever, otherwise the stitching may become misaligned or sewn incorrectly.

Memo

● We recommend that you practice making a buttonhole on a scrap piece of fabric before you try it on an actual garment.

● When making buttonholes on soft fabrics, place a stabilizer material on the underside of the fabric.

■ Making a buttonhole

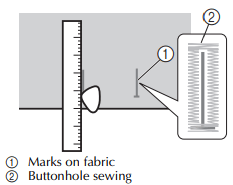

1. Using tailor’s chalk, mark the position and length of the buttonhole on the fabric.

2. Attach the buttonhole foot “A” and set the pattern selection dial to Buttonhole.

3. Open the button plate and insert the button.

■ If the button does not fit in the button guide plate

Add together the diameter and thickness of the button, and then set the button guide plate to the calculated length. (The distance between the markings on the presser foot scale is 5 mm (3/16 inch).)

Example: For a button with a diameter of 15 mm (9/16 inch) and a thickness of 10 mm (3/8 inch), the button guide plate should be set to 25 mm (1 inch) on the scale.

4. Pass the upper thread down through the hole in the presser foot.

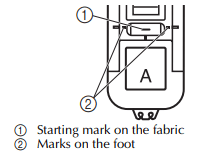

5. You need to sew the front bar tack first. Lower the presser foot to align the marks on the foot with the mark on the fabric.

6. Lower the buttonhole lever and push it back slightly.

7. While gently holding the upper thread, start the machine.

8. The bar tacks of the buttonhole are sewn in the order shown.

9. Stop the machine when buttonhole stitching is finished.

Note

● If buttonhole sewing was interrupted, sew trial stitching one or two times on a scrap piece of fabric before continuing to sew the project. Stitching that is continued after being interrupted may be sewn incorrectly.

● If thick seams are being sewn and the fabric does not feed, sew with the coarser (longer) stitch.

10. Raise the needle and the presser foot lever, remove the fabric, and cut the thread.

11. Raise the buttonhole lever to its original position.

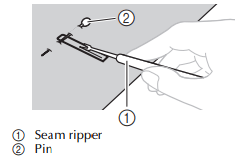

12. Insert a pin at the end of the buttonhole stitching to prevent the stitching from being cut, and then use a seam ripper to cut towards the pin and open the buttonhole.

MAINTENANCE

Restrictions on oiling

In order to prevent damaging this machine, it must not be oiled by the user.

This machine was manufactured with the necessary amount of oil applied to ensure correct operation, making periodic oiling unnecessary.

If problems occur, such as difficulty turning the handwheel or an unusual noise, immediately stop using the machine, and contact your authorized dealer or the nearest authorized service center.

Precautions on storing the machine

Do not store the machine in any of the locations described below, otherwise damage to the machine may result, for example, rust caused by condensation.

- Exposed to extremely high temperatures

- Exposed to extremely low temperatures

- Exposed to extreme temperature changes

- Exposed to high humidity or steam

- Near a flame, heater or air conditioner

- Outdoors or exposed to direct sunlight

- Exposed to extremely dusty or oily environments

Note In order to extend the life of this machine, periodically turn it on and use it. Storing this machine for an extended period of time without using it may reduce its efficiency.

Cleaning

1. Turn off the machine and unplug it.

2. Raise the needle and the presser foot.

3. Loosen the presser foot screw and the needle clamp screw to remove the presser foot holder and the needle.

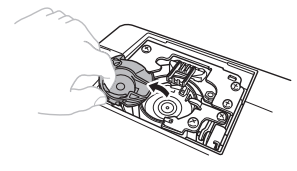

4. Using the oval screwdriver, remove the two screws. Lift up the needle plate as shown in the illustration, and then slide the needle plate to the left to remove it.

5. Grasp the bobbin case, and then lift it out to the left.

6. Use the cleaning brush or a vacuum cleaner to remove any dust from the race and its surrounding area.

• Do not apply oil to the bobbin case

7. Insert the bobbin case so that the ▲ mark on the bobbin case aligns with the ● mark on machine as shown below.

• Align the ▲ and ● marks.

• Make sure that the indicated points are aligned before installing the bobbin case.

8. Install the needle plate, and then tighten the screws.

• Make sure that you install the needle plate securely.

TROUBLESHOOTING

Symptom | Possible cause | How to put it right | Page |

| The sewing machine does not work. | The main power switch is turned off. | Turn on the main power switch. | 7 |

| The bobbin-winder shaft is pushed to the right. | Move the bobbin-winder shaft to the left. | 16 | |

| You have not used the foot controller properly | Use the foot controller properly. | 7 | |

| Fabric being sewn with the machine cannot be removed. | Thread is tangled below the needle plate | Lift up the fabric and cut the threads below it, and clean the race. | 47 |

| The needle breaks. | The needle is incorrectly installed. | Correctly install the needle. | 7 |

| The needle clamp screw is loose. | Use the oval screwdriver to firmly tighten the screw | 8 | |

| The needle is bent or blunt. | Replace the needle. | 7 | |

| The upper thread was not threaded correctly. | Correct the upper threading. | 19 | |

| You have not used the right combination of fabric, thread and needle. | Choose a thread and needle that are appropriate for the type of fabric. | 24 | |

| The presser foot you are using is not appropriate for the type of stitch that you want to sew. | Attach the presser foot that is correct for the type of stitch that you want to sew. | - | |

| The upper thread tension is too tight. | Loosen the upper thread tension. | 29 | |

| You are pulling the fabric too much. | Lightly guide the fabric. | - | |

| You have not fitted the spool properly | Fit the spool properly. | 19, 27 | |

| The area around the hole in the needle plate or the presser foot is scratched. | Replace the needle plate. Contact your retailer or the nearest authorized service center. | - | |

| The bobbin case is scratched. | Replace the bobbin case. Contact your retailer or the nearest authorized service center. | - | |

| You have not used a bobbin that has been designed for this machine. | Use a bobbin that has been designed for this machine. | 15 | |

| The upper thread breaks. | You have not threaded the upper thread properly. (For example, you have not fitted the spool properly, or the thread has come out of the guide above the needle.) | Correct the upper threading. | 19 |

| There are knots or tangles in the thread. | Remove any knots or tangles. | - | |

| The needle is not appropriate for the thread you are using. | Choose a needle that is appropriate for the type of stitch. | 24 | |

| ▼ The upper-thread tension is too tight. | Loosen the upper thread tension. | 29 | |

| The needle is bent or blunt. | Replace the needle. | 7 | |

| The needle is incorrectly installed. | Correctly install the needle. | 7 | |

| The area around the hole in the needle plate or the presser foot is scratched. | Replace the needle plate. Contact your retailer or the nearest authorized service center. | - | |

| The bobbin case is scratched, or has a burr on it. | Replace the bobbin case. Contact your retailer or the nearest authorized service center. | - | |

| You have not used a bobbin that has been designed for this machine. | Use a bobbin that has been designed for this machine. | 15 | |

| The lower thread is tangled or breaks. | You have not wound the bobbin thread properly. | Wind the bobbin thread properly. | 15 |

| The bobbin is scratched or does not turn smoothly. | Replace the bobbin. | - | |

| The thread is tangled. | Remove the tangled thread and clean the race. | 47 | |

| You have not used a bobbin that has been designed for this machine. | Use a bobbin that has been designed for this machine. | 15 | |

| Bobbin is set incorrectly | Reset the bobbin thread correctly. | 17-18 | |

| The thread tension is incorrect. | You have not threaded the upper thread properly. | Correct the upper threading. | 19 |

| You have not wound the bobbin thread properly. | Wind the bobbin thread properly | 15 | |

| You have not threaded the right combination of thread and needle for the fabric you are using. | Choose a thread and needle that are appropriate for the type of fabric. | 24 | |

| You have not attached the presser foot holder properly. | Attach the presser foot holder properly. | - | |

| The thread tension is incorrect. | Adjust the tension of the upper thread. | 29 | |

| You have not used a bobbin that has been designed for this machine. | Use a bobbin that has been designed for this machine. | 15 | |

| Bobbin is set incorrectly. | Reset the bobbin thread correctly. | 17-18 | |

| The fabric is wrinkled. | You have not threaded the upper thread properly or fitted the bobbin properly. | Thread the upper thread and wind the bobbin thread properly. | 15-22 |

| You have not fitted the spool properly. | Fit the spool properly. | 19-27 | |

| You have not used the right combination of fabric, thread and needle. | Choose a thread and needle that are appropriate for the type of fabric. | 24 | |

| The needle is bent or blunt. | Replace the needle. | 7 | |

| If thin fabrics are being sewn, the fabric is not being fed correctly. | Sew with stabilizer material under the fabric. | 27 | |

| If thin fabrics are being sewn, the stitch is too coarse. | Shorten the stitch length. | 14 | |

| The presser foot you are using is not appropriate for the type of stitch that you want to sew. | Attach the presser foot that is correct for the type of stitch that you want to sew. | 40 | |

| The thread tension is incorrect. | Adjust the tension of the upper thread | 29 | |

| Stitches are skipped. | You have not threaded the upper thread properly. | Correct the upper threading | 19 |

| You have not used the right combination of fabric, thread and needle. | Choose a thread and needle that are appropriate for the type of fabric. | 24 | |

| The needle is bent or blunt. | Replace the needle. | 7 | |

| The needle is incorrectly installed. | Correctly install the needle. | 7 | |

| Dust has accumulated under the needle plate or in the bobbin case. | Remove the needle plate and clean the plate and the bobbin case. | 47 | |

| The needle threader can not be used. | The needle has not been raised to the correct position. | Raise the needle by turning the handwheel toward you (counterclockwise) so that the mark on the wheel points up. | 21 |

| You have not inserted the needle properly. | Insert the needle properly. | 7 | |

| The stitch is not sewn correctly. | The presser foot that you are using is not correct for the type of stitch. | Attach the presser foot that is correct for the type of stitch that you want to sew. | - |

| The thread tension is incorrect. | Adjust the tension of the upper thread. | 29 | |

| The thread is tangled. | Remove the tangled thread. If the thread is tangled in the bobbin case, clean the bobbin case. | 47 | |

| The fabric does not feed | The stitch is too fine. | Lengthen the stitch length. | - |

| The darning plate is fitted on the needle plate. | Remove the darning plate. | - | |

| You have not used the right combination of fabric, thread and needle. | Choose a thread and needle that are appropriate for the type of fabric. | 24 | |

| The thread is tangled, for example, in the race. | Remove the tangle thread. If the thread is tangled in the race, clean the race. | 47 | |

| The presser foot you are using is not appropriate for the type of stitch that you want to sew. | Attach the presser foot that is correct for the type of stitch that you want to sew. | 40 |

See other models: HL-L2370DW(XL) MFC-J650DW TD-4100N HL-L6250DW QL-650TD