Loading ...

Loading ...

Loading ...

Replacing the Needle

GETTING READY

Basic operations B-29

B

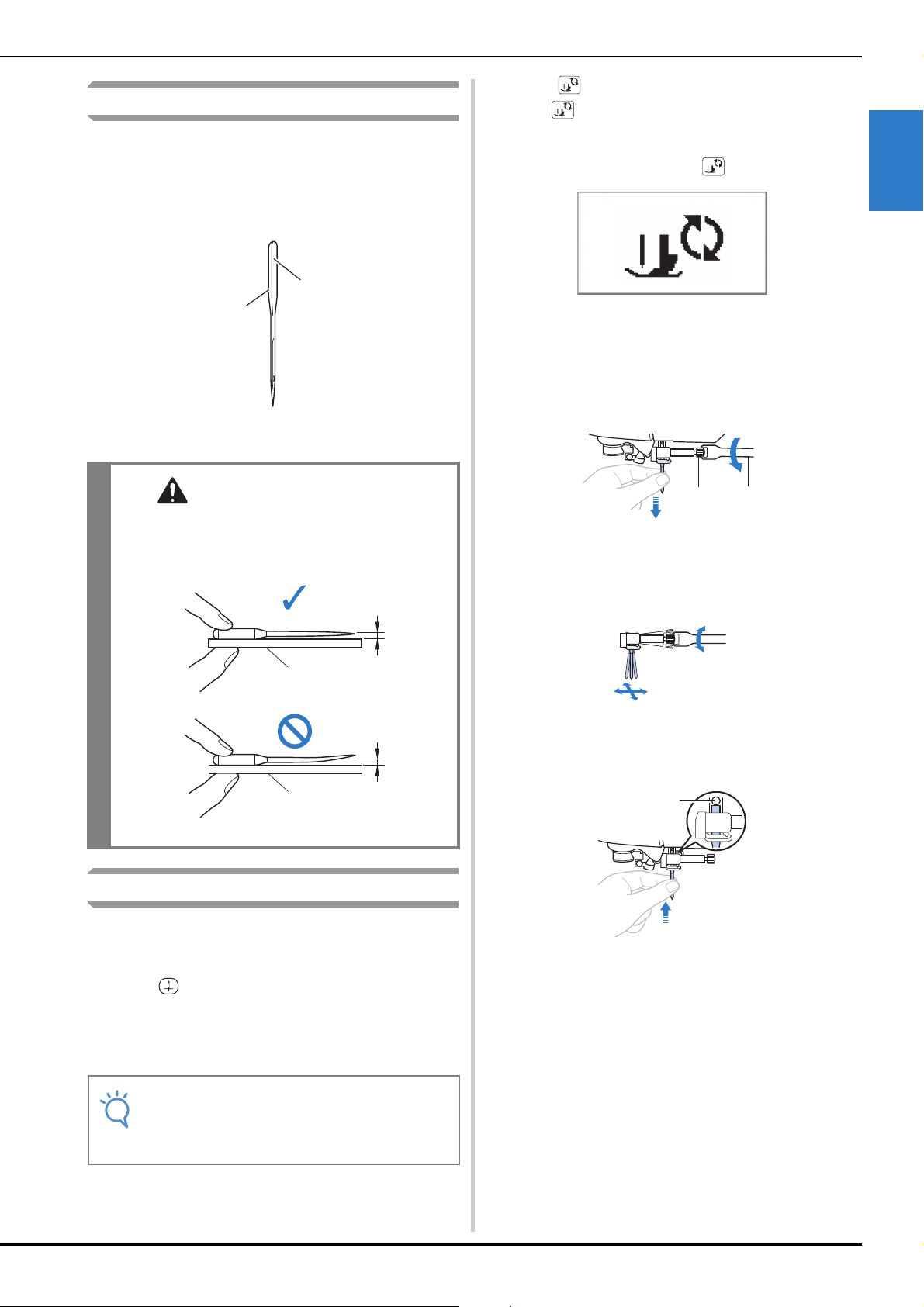

Checking the needle

Sewing with a bent needle is extremely dangerous since the

needle may break while the machine is being operated.

Before using the needle, place the flat side of the needle on a

flat surface and check that the distance between the needle

and the flat surface is even.

1 Flat side

2 Needle type marking

Replacing the needle

Use the screwdriver and a needle that has been determined to

be straight according to the instructions in “Checking the

needle”.

a

Press (Needle position button) once or twice to

raise the needle.

b

Place fabric or paper under the presser foot to cover

the hole in the needle plate.

c

Lower the presser foot.

d

Press .

• If is pressed while the presser foot is raised, an

error message appears. Lower the presser foot.

→ The screen changes, and all keys and operation

buttons are locked (except ).

e

Hold the needle with your left hand, and then use a

screwdriver to turn the needle clamp screw toward

you (counterclockwise) to remove the needle.

• The needle clamp screw can also be loosened or

tightened with the L-shaped (or disc-shaped)

screwdriver.

1 Screwdriver

2 Needle clamp screw

• Do not apply a strong force when loosening or

tightening the needle clamp screw, otherwise certain

parts of the machine may be damaged.

f

With the flat side of the needle toward the rear of the

machine, insert the needle until it touches the needle

stopper.

1 Needle stopper

CAUTION

• If the distance between the needle and the flat

surface is not even, the needle is bent. Do not

use a bent needle.

1 Flat surface

Note

• Before replacing the needle, cover the hole in the

needle plate with fabric or paper to prevent the

needle from falling into the machine.

1

2

1

1

2

1

1

Loading ...

Loading ...

Loading ...