Loading ...

Loading ...

Loading ...

English 5

Electrical Requirements

IMPORTANT

Observe all governing codes and ordinances.

It is the customer’s responsibility:

To contact a qualied electrical installer.

To assure that the electrical installation is adequate and in

conformance with National Electrical Code, ANSI/NFPA 70

— latest edition*, or CSA Standards C22.1-94, Canadian

Electrical Code, Part 1 and C22.2 No.0-M91 - latest edition** and all local

codes and ordinances.

If codes permit and a separate ground wire is used, it is recommended

that a qualied electrician determine that the ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

■ A 120 volt, 60 Hz., AC only, 15-amp, fused electrical circuit is

required.

■ If the house has aluminum wiring, follow the procedure below:

1. Connect a section of solid copper wire to the pigtail leads.

2. Connect the aluminum wiring to the added section of

copper wire using special connectors and/or tools designed

and UL listed for joining copper to aluminum.

■ Follow the electrical connector manufacturer’s recommended

procedure. Aluminum/copper connection must conform with local

codes and industry accepted wiring practices.

■ Wire sizes and connections must conform with the rating of

the appliance as specied on the model/serial rating plate.

The model/serial plate is located behind the lter on the rear

wall of the range hood.

■ Wire sizes must conform to the requirements of the National

Electrical Code, ANSI/NFPA 70 (latest edition), or CSA

Standards C22. 1-94, Canadian Electrical Code, Part 1 and

C22.2 No. 0-M91 (latest edition and all local codes and

ordinances.

Venting Requirements (ducted model only)

• Vent system must terminate outdoors.

• Do not terminate the vent system in an attic or other enclosed area.

• Do not use a 4” (10.2 cm) laundry-type wall cap.

• Use metal vent only. Rigid metal vent is recommended.

Plastic or metal foil vent is not recommended.

• The length of the vent system and the number of elbows should

be kept to a minimum to provide efcient performance.

For the most efcient and quiet operation:

• Use no more than three 90° elbows.

• Make sure there is a minimum of 24” (61 cm) of straight vent

between the elbows if more than 1 elbow is used.

• Do not install 2 elbows together.

• Use clamps to seal all joints in the vent system.

• The vent system must have a damper. If the roof or wall cap

has a damper, do not use the damper supplied with the range

hood.

• Use caulking to seal the exterior wall or roof opening around the cap.

• The size of the vent should be uniform.

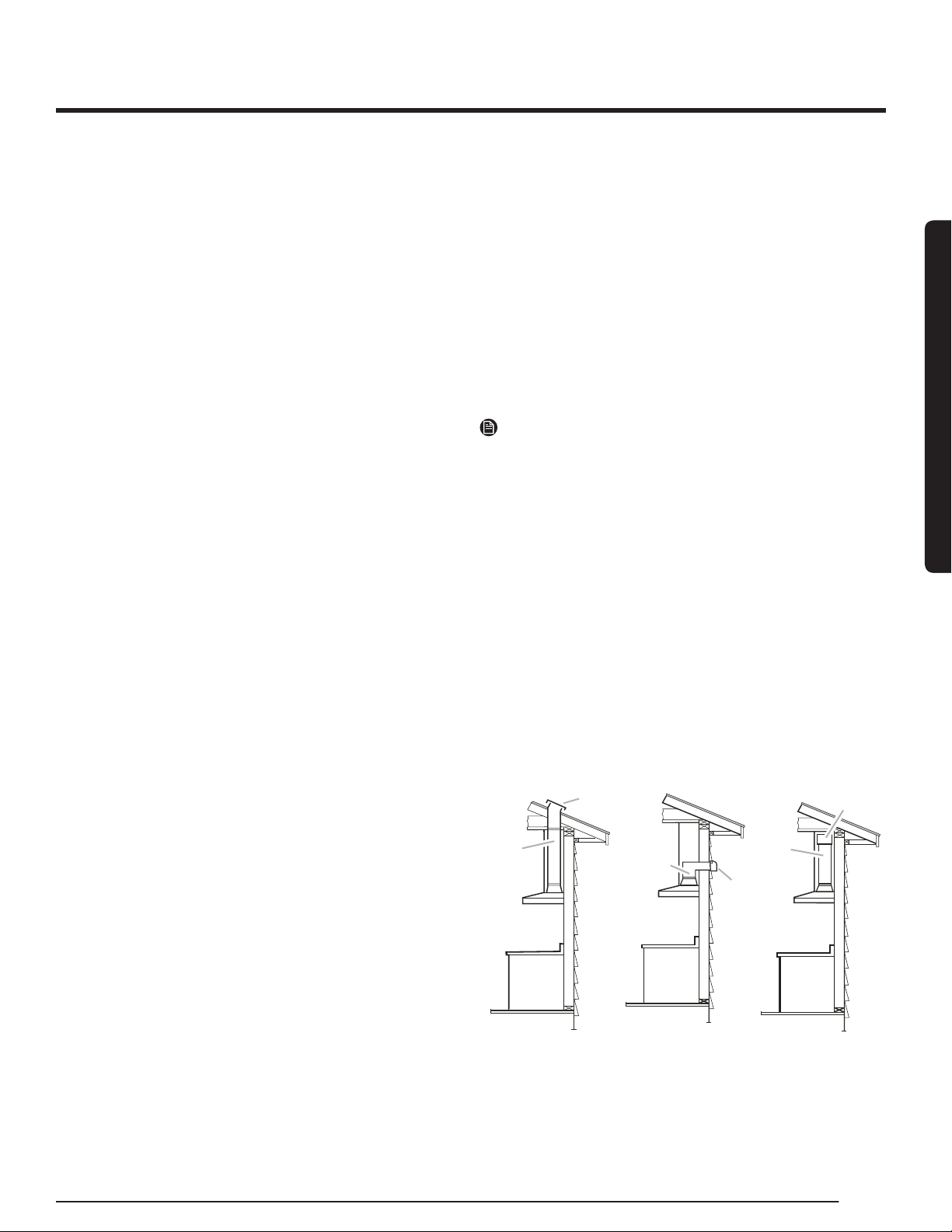

Venting Methods

This canopy hood is factory set for venting through the roof or

wall. A 6” (15.2 cm) round vent system is needed for installation (not

included). The hood exhaust opening is 6” (15.2 cm) round.

NOTE

Flexible vent is not recommended. Flexible vent creates back pressure

and air turbulence that greatly reduce performance. The vent system can

terminate either through the roof or wall. To vent through a wall, a 90°

elbow is needed.

Mounting Height

Select a mounting height between a minimum of 24” (61 cm) for an

electric cooking surface, a minimum of 30” (76.2 cm) for a gas cooking

surface, and a suggested maximum of 36” (91.4 cm) above the range to

the bottom of the hood.

Rear discharge

A 90° elbow may be installed immediately above the hood.

For Non-Vented (recirculating) Installations

If it is not possible to vent cooking fumes and vapors to the outside.

the hood can be used in the non-vented (recirculating) version. tting a

charcoal lter and the deector. Fumes and vapors are recycled through

the top grille.

Roof Venting Wall Venting Recirculating

A

B

A

B

B

A

A. Roof cap

B. 6” (15.2 cm) round vent

A.Wall cap

B. 6” (15.2 cm) round vent

A. Deector

B. 6” (15.2 cm) round vent

Installation Requirements

Installation Requirements

Loading ...

Loading ...

Loading ...