Documents: Go to download!

User Manual

- User Manual - (English)

- Warranty Guide - (English)

- CA Prop 65 - (English)

- CONTROLS & FEATURES

- OPERATION

- MAINTENANCE

- TROUBLESHOOTING

- SPECIFICATIONS

Table of contents

Operator’s Manual Gas Snow Blower

CONTROLS & FEATURES

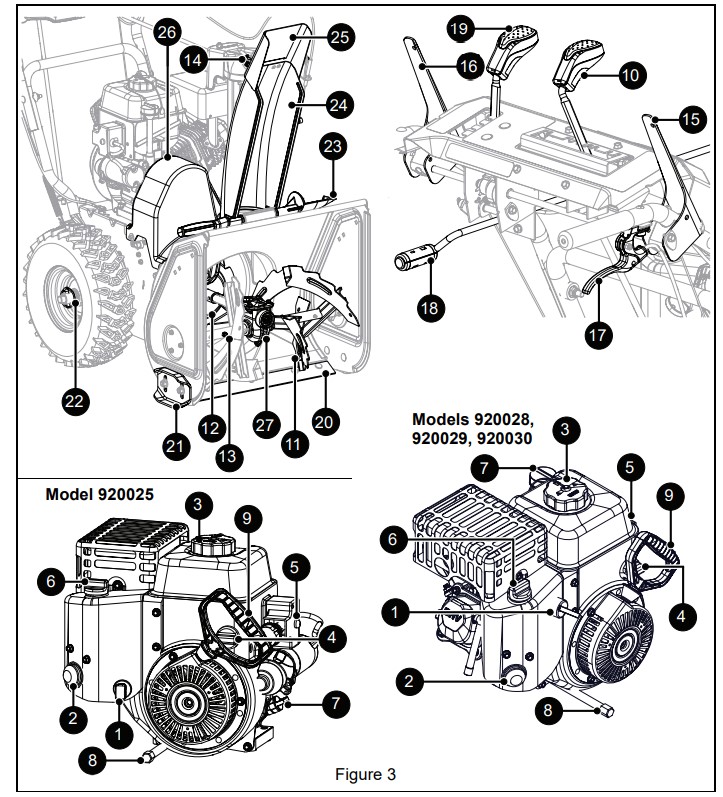

1. Engine Key 2. Primer Bulb 3. Fuel Tank and Cap 4. Fuel Valve 5. Electric Start Button 6. Choke Control Knob 7. Oil Fill / Dipstick 8. Oil Drain 9. Recoil Starter Handle 10. Speed Selector Lever 11. Auger 12. Impeller 13. Shear Bolt (2) 14. Replacement Shear Bolt (2) 15. Attachment Clutch Lever | 16. Traction Drive Clutch Lever 17. Height Adjustment Lever (Model 920028) 18. Discharge Chute Rotation Lever 19. Discharge Chute Deflector Lever 20. Scraper Blade 21. Skid Shoe (2) 22. Axle Lock Pin (2) (Models 920025, 920030) 23. Snow Clean-out Tool 24. Discharge Chute 25. Discharge Chute Deflector 26. Belt Cover 27. Gearcase |

OPERATION

IMPORTANT: All references to left, right, front or rear are given from the perspective of operator in operator’s position, facing the direction of forward travel.

EMERGENCY STOPPING

- Release both clutch levers.

- Turn engine key to stop position and remove key.

- Wait for all moving parts to stop before leaving operator’s position.

BEFORE OPERATING UNIT

IMPORTANT: Register your product! See Register Your Product! on page 1.

1. Check for a frozen impeller.

a. Turn engine key to stop position and remove key.

b. Engage attachment clutch lever and pull recoil starter handle.

c. If handle does not pull, move unit to a warm area to thaw.

2. Check fuel level and add fuel if needed.

IMPORTANT: Use fresh unleaded fuel with an octane rating of at least 87. DO NOT use E85 blended fuels; the engine is not E20 / E30 / E85 compatible. The maximum recommended ethanol content is 10%. Ariens recommends using a quality fuel stabilizer in all fuel. See Short Term on page 27.

3. Check engine oil level and add oil if needed. Refer to engine manual.

4. Check function of controls.

- Attachment Clutch Lever

- Traction Drive Clutch Lever

- Dual Handle Interlock

5. Know how to stop in an emergency. See Emergency Stopping on page 11.

START THE ENGINE

1. Electric Start: Connect power cord to starter and then into 120V 3-wire grounded outlet.

IMPORTANT: Use a power cord that is UL listed or CSA certified, rated for a minimum of 13 amps, grounded and labeled as suitable for outdoor use.

2. Turn fuel valve to on position.

3. Models 920028, 920029, 920030: Insert engine key and set engine switch to run position. Model 920025: Insert engine key.

4. Cold Engines Only: Press primer bulb 3 times.

5. Turn choke control knob to on position.

6. Electric Start: Press electric start button.

NOTICE: DO NOT run starter more than 10 times at intervals of 5 seconds on / 5 seconds off or overheating and damage may occur.

7. Recoil Start: Pull recoil starter handle.

a. Grasp handle and pull rope out slowly until it pulls harder.

b. Pull handle firmly and quickly with a rapid, continuous full-arm stroke. Repeat until engine starts. If engine does not start, see Troubleshooting on page 25.

c. Let handle rewind slowly after engine starts. DO NOT let handle snap against engine.

8. Gradually turn choke off as engine warms.

9. Electric Start: Disconnect power cord from outlet and then from starter.

OPERATE UNIT

1. Rotate discharge chute and move deflector to desired positions.

2. Select desired speed.

3. Engage attachment clutch.

NOTICE: Stop auger when traveling between work areas.

4. Engage traction drive clutch.

NOTICE: Release lever before changing speed.

Adjust Track Angle

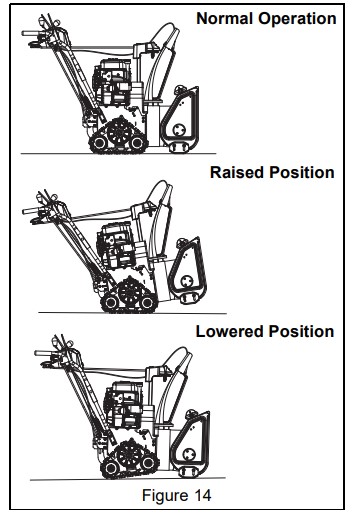

Model 920028

See Figure 14.

- To clear snow on gravel or uneven surfaces or to travel between work areas, squeeze height adjustment lever and push down on handlebars to raise auger housing.

- To clear packed snow, squeeze lever and lift up on handlebars to lower housing.

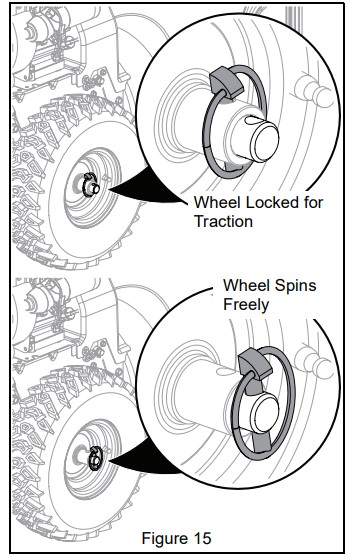

Set Axle Lock Pin

Models 920025, 920030

NOTICE: Wheels must be locked in the outer axle holes when using tire chains.

See Figure 15.

Axle lock pins may be positioned so both wheels lock with axle rotation for greater traction, or so one wheel is unlocked from axle and rotates freely for easier turning.

For greater traction:

1. Align both wheel hub holes with inner axle holes and insert lock pins.

For easier right turns:

1. Remove lock pin from right wheel hub.

2. Insert lock pin through outer axle hole.

For easier left turns:

1. Remove lock pin from left wheel hub.

2. Insert lock pin through outer axle hole.

IMPORTANT: Model 920029: When the unit is turned left or right, the Auto-TurnTM differential automatically unlocks wheels for easier turning. On a straight path, the differential locks both wheels in place for best traction.

Clear a Clogged Discharge Chute

- Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

- Use the snow clean-out tool to clear the clog.

- Return the tool to its storage position on the auger housing.

STOP THE ENGINE

- Release traction drive clutch lever.

- Run auger / impeller for a few minutes to remove loose or melting snow to prevent impeller from freezing.

- Release attachment clutch lever.

- Models 920028, 920029, 920030: Turn engine key to stop position and remove key. Model 920025: Remove engine key.

- Turn fuel valve to off position.

TRANSPORT UNIT

- Stop engine, remove key and close fuel valve.

- Secure unit chassis to transport vehicle.

NOTICE: NEVER secure from rods or linkages that could be damaged.

MAINTENANCE

Your Ariens dealer can provide service and adjustments to keep your unit operating at peak efficiency. Contact an authorized engine manufacturer’s service center for engine service.

SERVICE POSITION

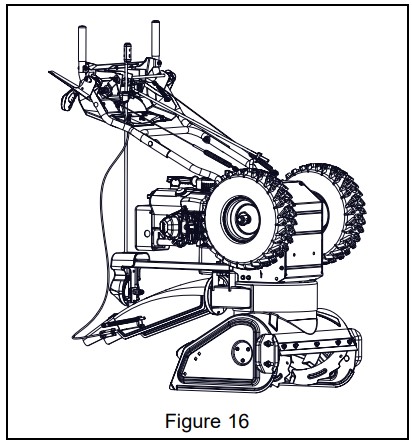

See Figure 16.

CHECK DUAL HANDLE INTERLOCK

- Stop engine.

- Engage attachment clutch and then the traction drive clutch.

- Release the attachment clutch lever. The attachment clutch should stay engaged until the traction drive clutch lever is released.

IMPORTANT: If dual handle interlock does not operate correctly, adjust or repair as directed in the service manual for your unit.

CHECK FASTENERS

Check for loose hardware

CHECK CLUTCH OPERATION

- Auger / impeller must stop within 5 seconds when attachment clutch lever is released.

- Wheels must stop quickly when traction drive clutch lever is released.

IMPORTANT: If clutches do not engage or disengage correctly, see Adjust Attachment Clutch & Brake on page 20 or Adjust Traction Drive Clutch on page 22. Refer to the service manual for your unit for more information about clutch repairs.

CHECK ENGINE OIL

NOTICE: Engine oil level must be maintained at correct level or engine damage may occur. Refer to engine manual.

CHANGE ENGINE OIL

Refer to engine manual.

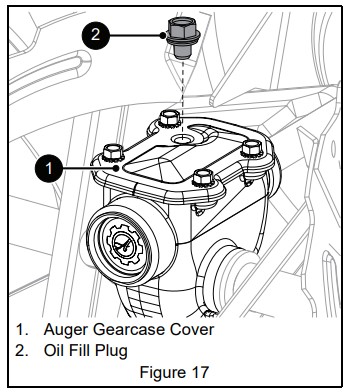

CHECK AUGER GEARCASE OIL

1. Place unit on flat, level surface.

2. Remove oil fill plug. See Figure 17.

IMPORTANT: DO NOT remove gearcase cover.

3. Check oil level with a suitable measuring device, such as a clean screwdriver and add oil if needed. Oil level must be 4.1 cm – 4.8 cm (1.6" – 1.9") from the flat surface of the gearcase cover.

IMPORTANT: Ariens recommends using only Ariens L3 synthetic severe duty gear lube (see Service Parts on page 14). Using other lubricants will not automatically void unit warranty, but the warranty will not cover damage caused by using unauthorized lubricants.

4. Inspect oil fill plug for wear or rubber deterioration and replace if needed.

5. Reinstall oil fill plug. Torque to 9 N•m (80 lb-in).

IMPORTANT: DO NOT over torque. Measurements are given in pound force inches (lb-in) and not pound force foot (lb-ft).

IMPORTANT: Incorrect torquing and failure to install or correctly torque oil fill plug may void gearcase warranty

LUBRICATE UNIT

Ariens recommends using Ariens Hi-Temp Grease or equivalent (see Service Parts) to lubricate fittings. Lubricate each season or every 25 hours of operation.

IMPORTANT: Wipe each fitting clean before and after lubrication.

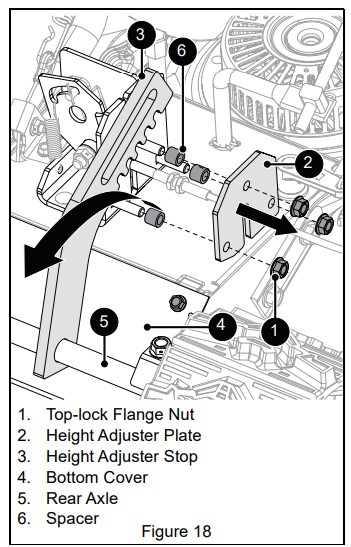

Remove Bottom Cover

Models 920025, 920029, 920030

- Place unit in service position. See Figure 16.

- Remove six hex bolts retaining cover and remove cover. Save for reinstallation.

Model 920028 See Figure 18.

- Place unit in service position. See Figure 16.

- Remove three top-lock flange nuts retaining height-adjuster plate to heightadjuster bracket.

- Remove height-adjuster plate and three spacers on the round head square neck bolts. The height-adjuster stop will be attached to the rear axle.

- Slide height-adjuster stop to the right and rotate it away from frame.

- Remove six bolts retaining bottom cover and remove cover. Rotate track carriage as needed to remove cover.

TROUBLESHOOTING

| Problem | Probable Cause | Correction |

|---|---|---|

| Engine will not start. | Engine key in stop position. | Turn engine key to run position. See Engine Key on page 9. |

| Choke is off. | Turn choke control knob to on position. See Choke Control Knob on page 9 | |

| Fuel valve is closed. | Open valve. See Fuel Valve on page 9. | |

| Fuel tank is empty. | Fill tank with fuel. See Before Operating Unit on page 11. | |

| Engine is not primed. | If engine is cold, press primer bulb three timesand start engine. Do not prime a warm engine. See Primer Bulb on page 9. | |

| gnition switch starter circuit is not functioning. | See your dealer for repair. | |

| Build up of dirt and residue around governor / carburetor. | Clean area around governor / carburetor. See the service manual for your unit | |

| Spark plug wire is disconnected. | Connect spark plug. Refer to engine manual. | |

| Spark plug is faulty. | Replace spark plug. Refer to engine manual. | |

| Excessive fuel in engine cylinder (flooded). | Turn choke control knob to off position and reattempt starting. See Start The Engine on page 11. | |

| Engine is faulty. | See your Ariens dealer or authorized engine manufacturer’s service center. | |

| Engine starts hard or runs poorly. | Fuel mixture is too rich. | Turn choke control knob to off position. See Choke Control Knob on page 9. |

| Spark plug is faulty, fouled or incorrectly gapped. | Clean and correctly set spark plug gap (refer to engine manual) or see your Ariens dealer. | |

| Fuel cap vent is blocked. | Install new fuel cap. | |

| Engine stops. | Fuel tank is empty. | Fill tank with fuel. See Before Operating Unit on page 11. |

| Fuel valve is closed. | Open valve. See Fuel Valve on page 9. | |

| Obstruction in auger or impeller. | Stop engine, remove key and wait for all moving parts to stop. Check for and remove obstruction before restarting. | |

| Contaminated fuel supply. | Replace with clean fuel. | |

| Spark plug is faulty. | Replace or clean spark plug. Refer to engine manual. | |

| Fuel cap vent is blocked. | Install new fuel cap. | |

| Unit runs briefly then stops. | A build up of fumes in the fuel tank is creating too much pressure in the fuel tank. | Slowly loosen the fuel tank cap. |

| Unit does not drive forward or in reverse. | Friction disc is worn. | Replace friction disc. Refer to the service manual for your unit. |

| Traction drive cable is not adjusted correctly. | Remove slack from cable. See Adjust Traction Drive Clutch on page 22. | |

| Traction belt is not functioning. | Repair or replace traction drive belt. Refer to the service manual for your unit | |

| Speed selector is not adjusted correctly. | Adjust speed selector. See Adjust Speed Selector Lever on page 19. | |

| Axle lock pins set to allow both wheels to spin freely (Models 920025, 920030). | Position one or both axle lock pins in traction position. See Set Axle Lock Pin on page 12. | |

| Unit does not throw snow or throws it poorly. | Shear bolts are broken. | See Replace Shear bolts on page 18. |

| Attachment clutch / brake is not adjusted correctly. | See Adjust Attachment Clutch & Brake on page 20. | |

| Impeller is frozen in place. | Move unit to a warm place to thaw. | |

| Ice or debris is obstructing auger. | Stop engine, remove key and wait for moving parts to stop. Check for and remove obstruction before restarting. | |

| Discharge chute is clogged with snow. | Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool. Clean discharge chute and auger housing with clean-out tool. DO NOT use your hands. | |

| Auger drive belt is slipping, worn or damaged. | Adjust or replace auger drive belt. Refer to the service manual for your unit. | |

| Auger drive belt is loose or damaged. | Replace belt or adjust auger control cable. Refer to the service manual for your unit. | |

| Excessive snow is left behind. | Scraper blade is worn or damaged. | Adjust when worn and replace when damaged or when blade has been adjusted down as far as possible and does not touch ground or clear correctly. See Adjust Scraper Blade on page 18. |

| Small rubber beads collect in frame. | Friction disc wear. | This is normal friction disc wear and no correction is needed unless there are chunks or large pieces of rubber collecting in frame. If repair is needed, refer to the service manual for your unit. |

SPECIFICATIONS

*Engine output stated in gross torque per SAE J1940 as rated by engine manufacturer.

See other models: 921046 921045 920025