Documents: Go to download!

User Manual

- Owner's manual - (English, French, Spanish)

- CA Prop 65 - (English)

- INTRODUCTION AND SAFETY

- GENERAL INFORMATION AND SETUP

- OPERATION

- MAINTENANCE AND TROUBLESHOOTING

Table of contents

User Guide Craftsman CMXGIAC2500 Inverter Generator

INTRODUCTION AND SAFETY

Safety Rules

- The manufacturer cannot anticipate every possible circumstance that might involve a hazard. The warnings in this manual, and on tags and decals affixed to the unit are, therefore, not all inclusive.

- If using a procedure, work method or operating technique that the manufacturer does not specifically recommend, verify that it is safe for others. and does not render the equipment unsafe.

- Throughout this publication, and on tags and decals affixed to the generator, DANGER, WARNING, CAUTION, and NOTE blocks are used to alert personnel to special instructions about a particular operation that may be hazardous if performed incorrectly or carelessly. Observe them carefully.

- These safety warnings cannot eliminate the hazards that they indicate. Common sense and strict compliance with the special instructions while performing the action or service are essential to preventing accidents.

Electrical Hazards

- DANGER: Electrocution. Contact with bare wires, terminals, and connections while generator is running will result in death or serious injury.

- DANGER: Electrocution. Water contact with a power source, if not avoided, will result in death or serious injury. (000104)

- DANGER: Electrocution. In the event of electrical accident, immediately shut power OFF. Use nonconductive implements to free victim from live conductor. Apply first aid and get medical help.

- Failure to do so will result in death or serious injury. (000145)

- DANGER: Electrocution. Turn utility and emergency power supplies to OFF before connecting power source and load lines. Failure to do so will result in death or serious injury. (000116)

- WARNING: Equipment and property damage. Do not alter construction of, installation, or block ventilation for generator. Failure to do so could result in unsafe operation or damage to the generator. (000146)

- The National Electric Code (NEC) requires the frame and external electrically conductive parts of the generator be correctly connected to an approved earth ground.

- Local electrical codes may also require correct grounding of the generator. Consult with a local electrician for grounding requirements in the area.

- Use a ground fault circuit interrupter in any damp or highly conductive area (such as metal decking or steel work).

- Once generator has been started outside, connect elec- trical loads to extension cord(s) inside.

Exhaust and Location Hazards

- DANGER: Asphyxiation. Running engines produce carbon monoxide, a colorless, odorless, poisonous gas. Carbon monoxide, if not avoided, will result in death or serious injury. (000103)

- DANGER: Asphyxiation. The exhaust system must be properly maintained. Do not alter or modify the exhaust system as to render it unsafe or make it noncompliant with local codes and/or standards.

- Failure to do so will result in death or serious injury. (000179b)

- WARNING: Equipment and property damage. Do not alter construction of, installation, or block ventilation for generator. Failure to do so could result in unsafe operation or damage to the generator. (000146)

- WARNING: Asphyxiation. Always use a battery operated carbon monoxide alarm indoors and installed according to the manufacturer’s instructions. Failure to do so could result in death or serious injury. (000178a)

- If you start to feel sick, dizzy, or weak after the generator has been running, move to fresh air IMMEDIATELY. See a doctor, as you could have carbon monoxide poisoning.

- NEVER run a generator indoors or in a partly enclosed area such as garages.

- ONLY use outdoors and far away from windows, doors, vents, crawl spaces and in an area where adequate ventilation is available and will not accumulate deadly exhaust gas.

- Using a fan or opening a door will not provide sufficient ventilation.

- Point muffler exhaust away from people and occupied buildings.

Fire Hazards

- DANGER: Explosion and Fire. Fuel and vapors are extremely flammable and explosive. Add fuel in a well ventilated area. Keep fire and spark away.

- Failure to do so will result in death or serious injury. (000105)

- DANGER: Explosion and Fire. Do not overfill fuel tank. Fill to 1/2 inch from top of tank to allow for fuel expansion. Overfilling may cause fuel to spill onto engine causing fire or explosion which will result in death or serious injury. (000166b)

- WARNING: Personal injury. Do not insert any object through the air cooling slots. Generator can start at any time and could result in death, serious injury, and unit damage. (000142a)

- WARNING: Fire risk. Fuel and vapors are extremely flammable. Do not operate indoors.

- Doing so could result in death, serious injury, or property or equipment damage. (000281)

- WARNING: Explosion and fire risk. Do not smoke near unit. Keep fire and spark away. Failure to do so could result in death, serious injury, or property or equipment damage. (000282)

- WARNING: Explosion and Fire. Do not smoke while refueling unit. Failure to do so could result in death, serious injury, or property or equipment damage. (000284a)

- Allow at least 5 ft (1.5 m) of clearance on all sides of the generator when operating to prevent overheating and fire.

- Do not operate the generator if connected electrical devices overheat, if electrical output is lost, if engine or generator sparks, or if flames or smoke are observed while unit is running.

- Keep a fire extinguisher near the generator at all times.

Register Online

- WARRANTY SERVICE: Registering the product will help obtain warranty service if there is a problem with the product.

- CONFIRMATION OF OWNERSHIP: In case of an insurance loss, such as fire, flood or theft, the registration of ownership will serve as proof of purchase.

- FOR YOUR SAFETY: Registering the product will allow us to contact you in the unlikely event a safety notification is required under the Federal Consumer Safety Act.

GENERAL INFORMATION AND SETUP

Emissions

- The United States Environmental Protection Agency (US

- EPA) (and California Air Resources Board (CARB), for engines/equipment certified to California standards) requires that this engine/equipment complies with exhaust and evaporative emissions standards. Locate the emissions compliance decal on the engine to determine applicable standards

- For emissions warranty information, please reference the included emissions warranty. It is important to follow the maintenance specifications in the manual to ensure that the engine complies with the applicable emissions standards for the duration of the product’s life.

- 120 VAC, Duplex Outlet See Fig. C.

- The 120 volt outlet is overload protected by the 18 amp push button circuit breaker. Each outlet will power 120 volt AC, single-phase, 60 Hz electrical loads requiring up to 2200 Watts (2.2 kW). 001630 Fig. C

Start Dial (OFF/RUN/CHOKE)

- This controls the ON/OFF functions, choke, and fuel valve operation (Fig. D).

- The OFF position 1 stops the engine and shuts off fuel flow.

- The RUN position 2 is for normal operation and to gradually reduce the use of the choke.

- The CHOKE position 3 switches the fuel valve on to start the engine.

- NOTE: The CHOKE is not required to start a warm engine.

USB Outlets

- The 2–2.1 amp, 5 VDC USB outlets allow charging of compatible electronic devices.

- Generator Status Lights

- Overload LED (red): Indicates system overload 2 . During motor starting it is normal for the overload LED to illuminate for a few seconds. If LED stays illuminated and the ready LED turns off, the engine will continue to run without output power.

- Remove all applied loads and determine if attached devices exceed recommended output power. Check for faulty or shorted con- nections. To restore electrical output, turn dial OFF to reset. Start engine. If condition was corrected, the red

- LED will not illuminate and electrical output will be restored. Loads can be applied once the green LED illu- minates. If the red LED returns, contact the nearest Service Center.

- Low Oil Level LED (orange): Illuminates when oil level is below safe operating level. Engine shuts down 1 .

- Power LED (green): Indicates output from generator 3 unless there is a low oil or overload condition).

Circuit Breakers

The AC outlets are protected by an AC circuit breaker.

The DC outlets are protected by a DC circuit breaker. If the generator is overloaded or an external short circuit occurs, the circuit breaker will trip.

If this occurs, disconnect all electrical loads to determine the cause of the problem before using the generator again. Reduce the load if the circuit breaker is tripped.

NOTE: Continuous tripping of the circuit breaker may cause damage to generator or equipment.

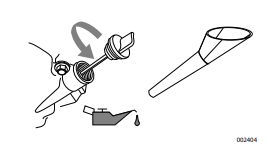

Add Engine Oil

- Engine damage. Verify proper type and quantity of engine oil prior to starting the engine.

- Failure to do so could result in engine damage.

NOTE:

- The generator is shipped without oil in the engine.

Add oil slowly and verify oil level often during filling process to prevent overfilling.

- Place generator on a level surface.

- Remove screws and side cover.

- Verify oil fill area is clean.

- Remove oil fill cap/oil dipstick and wipe oil dipstick clean.

- Insert funnel into oil fill opening. Add recommended engine oil as necessary. Climate determines required engine oil viscosity. See chart to select correct viscosity.

NOTE:

- Use petroleum based oil (supplied) for engine break-in before using synthetic oil.

- Remove funnel and insert oil dipstick into oil filler neck. Do not screw in.

- Remove oil dipstick and verify oil level is within safe operating range.

NOTE:

- Verify oil level often during filling process to prevent overfilling.

Install oil fill cap/dipstick and hand-tighten.

Install side cover and screws.

- Fuel requirements are as follows:

- Clean, fresh, unleaded gasoline.

- Minimum rating of 87 octane/87 AKI (91 RON).

- Up to 10% ethanol (gasohol) is acceptable (where available; non-ethanol fuel is recommended).

- DO NOT use E85.

- DO NOT use a gas oil mix.

- DO NOT modify engine to run on alternate fuels. Stabi- lize fuel prior to storage.

- Verify unit is OFF and cooled entirely prior to fueling.

- Place unit on level ground in a well ventilated area.

- Clean area around fuel cap.

- Turn fuel cap slowly to remove.

- Slowly add recommended fuel. Do not overfill.

NOTE:

- Fill to red insert inside filler neck.

OPERATION

Operation and Use Questions

- Call Customer Service at 1-888-331-4569 with questions or concerns about equipment operation and maintenance.

- Before Starting Engine

- Verify engine oil level is correct.

- Verify fuel level is correct.

- Verify unit is secure on level ground, with correct clearance and is in a well ventilated area.

- Grounding the Generator When In

Use

- The generator is equipped with an equipment ground connecting the generator frame and the ground terminals on the AC output outlets (see NEC 250.34 A . This allows the generator to be used as a portable without grounding the frame of the generator as specified in NEC 250.34 (Fig. J).

Neutral Floating

- The generator (stator winding) is isolated from the frame and from the AC outlet ground pin. Electrical devices that require a grounded outlet pin connection will not function if the outlet ground pin is not functional.

Know Generator Limits

- Overloading a generator can result in damage to the generator and connected electrical devices. Observe the following to prevent overload:

- Add up the total wattage of all electrical devices to be connected at one time. This total should NOT be greater than the generator's wattage capacity.

- The rated wattage of lights can be taken from light bulbs. The rated wattage of tools, appliances, and motors can be found on a data label or decal affixed to the device.

- If the appliance, tool, or motor does not give wattage, multiply volts times ampere rating to determine watts volts x amps = watts).

- Some electric motors, such as induction types, require about three times more watts of power for starting than for running. This surge of power lasts only a few seconds when starting such motors. Make sure to allow for high starting wattage when selecting electrical devices to connect to the generator:

- Calculate wattage needed to start the largest motor.

- Add the running watts of all other connected loads to that figure.

- Wattage Reference Guide is provided to assist in determining how many items the generator can operate at one time.

NOTE: All figures are approximate. See data label on appliance for wattage requirements.

Transporting/Tipping of the Unit

- Do not store or transport the unit at an angle greater than 15 degrees.

Starting Pull Start Engines

- Recoil hazard. Recoil could retract unexpectedly. Kickback could result in death or serious injury. (000183)

CAUTION:

- Equipment and property damage. Disconnect electrical loads prior to starting or stopping unit. Failure to do so could result in equipment and property damage. (000136)

- Rotate Start Dial to CHOKE 1 .

- Firmly grasp recoil handle and pull slowly until increased resistance is felt. Pull rapidly up and away.

- When engine starts, rotate Start Dial to RUN 2 . Choke operation is reduced as Start Dial is rotated towards RUN.

NOTE:

- If engine fires, but does not continue to run, rotate the Start Dial to OFF and repeat starting instructions.

IMPORTANT NOTE:

- Do not overload generator or individual panel outlets. If an overload occurs, the overload

- LED will illuminate and AC output ceases. To correct, see Generator Status Lights. Read Know Generator Limits carefully

Generator Shut Down

- Equipment and property damage. Disconnect electrical loads prior to starting or stopping unit. Failure to do so could result in equipment and property damage. (000136)

- Shut off all loads and unplug electrical loads from generator panel outlets.

- Let engine run at no-load for several minutes to sta- bilize internal temperatures of engine and genera- tor.

- Rotate Start Dial to OFF 3 .

Starting Hot Engines

- Equipment and property damage. Disconnect electrical loads prior to starting or stopping unit. Failure to do so could result in equipment and property damage. (000136)

- Turn Start Dial from STOP to RUN. This will open the fuel valve and permit starting.

- Firmly grasp recoil handle and pull slowly until increased resistance is felt. Pull rapidly up and away.

Low Oil Level Shutdown System

The engine is equipped with a low oil level sensor that shuts down the engine automatically when the oil level drops below a specified level to prevent engine damage

The engine will not run until the oil has been filled to the proper level (Fig. L).

IMPORTANT NOTE:

- Verify correct engine oil and fuel levels before use.

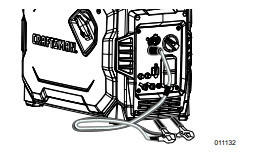

- Charging a 12 VDC Battery

WARNING:

- Explosion. Batteries emit explosive gases while charging. Keep fire and spark away.

- Wear protective gear when working with batteries. Failure to do so could result death or serious injury. (000137a)

WARNING: Risk of burns. Batteries contain sulfuric acid and can cause severe chemical burns.

Wear protective gear when working with batteries. Failure to do so could result death or serious injury. (000138a)

WARNING: Environmental Hazard. Aways recycle batteries at an official recycling center in accordance with all local laws and regulations. Failure to do so could result in environmental damage, death or serious injury. (000228)

NOTE: A battery may lose some of its charge when not in use for prolonged periods of time.

The DC charging output is not regulated. The circuit breaker does not prevent over charging a battery. Battery charging should be done in a dry location (Fig. M).

Start generator.

- Plug Battery Charging Cable into Battery Charger

- Output jack, located on the control panel.

- Connect positive (+) battery clamp (red wire) to battery FIRST.

- Connect negative (-) battery clamp (black wire) to battery SECOND.

NOTE: This outlet cannot recharge 6-volt batteries and cannot be used to crank an engine having a discharged battery.

Fig. M

Parallel Operation

- For output power up to 4400 running Watts, two inverters can operate in parallel using Parallel Kit (optional).

- See the Parallel Kit Operator’s Manual or contact Customer Service at 1-888-331-4569.

NOTE:

- All connections to the parallel kit should be made while both inverters are turned off and all loads disconnected.

- Make appropriate parallel connections to the out- lets on each inverter as outlined in the instruction manual supplied with the kit.

NOTE:

- Do not disconnect any parallel kit connections once the units are running.

- Start both units per starting instructions. Once the green output indicator illuminates, devices can be connected and turned on using the parallel kit outlet.

- Follow Generator Shut Down instructions.

NOTE: For inverters, load applied to the parallel kit is not to exceed 4750 starting Watts due to a 5% power loss when paralleling. See manual.

NOTE:

- Only use approved parallel kit.

- Push the button of the protector to reset the circuit breaker.

MAINTENANCE AND TROUBLESHOOTING

Maintenance

- Regular maintenance will improve performance and extend engine/equipment life. Contact Customer Service at 1-888-331-4569, or WWW.CRAFTSMAN.COM to find a dealer for maintenance work to be performed.

- Regular maintenance, replacement or repair of the emissions control devices and systems may be performed by any repair shop or person of the owner’s choosing. However, to obtain emissions control warranty service free of charge, the work must be performed by a CRAFTSMAN service dealer. See the emissions warranty.

NOTE: Call 1-888-331-4569 with questions about component replacement.

Maintenance Schedule

- Follow maintenance schedule intervals, whichever occurs first according to use.

NOTE: Adverse conditions will require more frequent service.

NOTE: All required service and adjustments should be each season as detailed in the following chart

Preventive Maintenance

WARNING: Personal injury. Do not insert any object through the air cooling slots. Generator can start at any time and could result in death, serious injury, and unit damage. (000142a)

- Dirt or debris can cause incorrect operation and equipment damage. Clean generator daily or before each use.

- Keep area around and behind muffler free from combustible debris. Inspect all cooling air openings on generator.

- Use a damp cloth to wipe exterior surfaces clean.

- Use a soft bristle brush to loosen caked on dirt, oil, etc.

- Use a vacuum to pick up loose dirt and debris.

- Low pressure air (not to exceed 25 psi) may be used to blow away dirt. Inspect cooling air slots and openings on generator. These openings must be kept clean and unobstructed.

NOTE: DO NOT use a garden hose to clean generator. Water can enter engine fuel system and cause problems. If water enters generator through cooling air slots, some water will be retained in voids and crevices of rotor and stator winding insulation. Water and dirt buildup on generator internal windings will decrease insulation resistance of windings.

Engine Maintenance

WARNING: Personal injury. Do not insert any object through the air cooling slots. Generator can start at any time and could result in death, serious injury, and unit damage. (000142a)

WARNING: Accidental start-up. Disconnect spark plug wires when working on unit. Failure to do so could result in death or serious injury. (000141)

Engine Oil Recommendations

- To maintain the product warranty, the engine oil should be serviced in accordance with the recommendations of this manual.

- For your convenience, service items designed and intended for use on this product are available from the manufacturer including engine oil, spark plug(s), a shop towel, and a funnel. These items can be obtained by contacting Customer Service at 1-888-331-

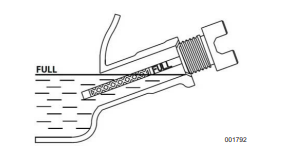

Inspect Engine Oil Level

- Risk of burns. Allow engine to cool before draining oil or coolant. Failure to do so could result in death or serious injury. (000139)

- See Fig. N and Fig. O. Inspect engine oil level prior to each use, or every eight hours of operation.

- Place generator on a level surface.

- Remove screws and side cover.

- Clean area around oil fill.

- Remove oil fill cap/oil dipstick and wipe oil dipstick clean.

- Insert oil dipstick into oil filler neck. Do not screw it in.

- Remove oil dipstick and verify oil level is within safe operating range.

Add recommended engine oil as necessary.

NOTE: Verify oil level often during filling process to prevent overfilling.

Install oil fill cap/oil dipstick and hand-tighten.

NOTE: Some units have more than one oil fill location. It is only necessary to use one oil fill point.

Change Engine Oil

WARNING: Accidental start-up. Disconnect spark plug wires when working on unit. Failure to do so could result in death or serious injury. (000141)

When using generator under extreme, dirty, or dusty conditions, or in extremely hot weather, change oil more frequently (Fig. P and Fig. Q).

NOTE: Don’t pollute. Conserve resources. Return used oil to collection centers.

Change oil while engine is still warm from running, as follows:

- Place generator on a level surface.

- Remove screws, side cover, and spark plug cover.

- Disconnect spark plug wire from spark plug and place spark plug wire where it cannot contact spark plug.

- Clean area around oil fill and oil drain plug.

- Remove oil fill cap/oil dipstick and wipe oil dipstick clean.

- Tip unit and drain oil completely into a suitable con- tainer.

- Install oil drain plug and tighten securely.

- Insert funnel into oil fill opening. Add recom- mended engine oil as necessary.

- Remove funnel and insert oil dipstick into oil filler neck. Do not screw it in.

- Remove oil dipstick and verify oil level is within safe operating range.

NOTE:

- Verify oil level often during filling process to prevent overfilling.

- Install oil fill cap/oil dipstick and hand-tighten.

- Wipe up any spilled oil.

- Connect spark plug wire.

- Install side panel, screws, and spark plug cover.

- Dispose of used engine oil in accordance with all applicable regulations.

Air Filter

- Engine will not run correctly and may be damaged if run with a dirty air filter. Service air filter more frequently in dirty or dusty conditions (Fig. R).

To service air filter:

- Remove screws and side cover.

- Remove bolt A and remove air filter cover.

- Wash filter B in soapy water. Squeeze dry in clean cloth (DO NOT TWIST).

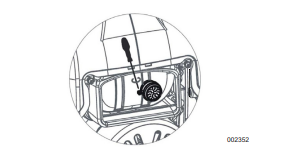

- Service Spark Plug

To service spark plug (Fig. S):

- Remove spark plug cover, and disconnect spark plug wire. Place spark plug wire where it cannot contact spark plug.

- Clean area around spark plug.

- Remove and inspect spark plug.

- Inspect electrode gap with feeler gauge and set spark plug gap to 0.6–0.7mm (0.024–0.028 in).

NOTE:

- Replace spark plug if electrodes are pitted, burned or porcelain is cracked. Use ONLY recommended replacement plug. See Product Specifications.

- Install spark plug finger tight, and tighten an additional 3/8 to one-half turn using spark plug wrench.

- Connect spark plug wire and install spark plug cover.

Inspect Muffler and Spark Arrester

- It is a violation of California Public Resource Code,

- Section 4442, to use or operate the engine on any forestcovered, brush-covered, or grass-covered land unless the exhaust system is equipped with a spark arrester, as defined in Section 4442, maintained in effective working order. Other states or federal jurisdictions may have similar laws.

- Contact original equipment manufacturer, retailer, or dealer to obtain a spark arrester designed for exhaust system installed on this engine.

NOTE: Use ONLY original equipment replacement parts.

- Inspect muffler for cracks, corrosion, or other damage.

- Remove spark arrester, if equipped, and inspect for damage or carbon blockage. Replace parts as required.

Inspect Spark Arrester Screen

WARNING: Hot surfaces. When operating machine, do not touch hot surfaces. Keep machine away from combustibles during use. Hot surfaces could result in severe burns or fire. (000108)

Clean Spark Arrestor Screen

- The engine exhaust muffler has a spark arrestor screen.

- Inspect and clean the spark arrestor screen every 100 hours of operation or every season, whichever comes first.

- To service spark arrestor screen (Fig. T):

Remove clamp to remove retainer.

- Slide spark arrestor screen out from muffler outlet tube.

- Inspect spark arrestor screen and replace if torn, perforated, or otherwise damaged. Do NOT use a faulty spark arrestor screen. If spark arrestor screen is not damaged, clean with a commercial solvent.

- Replace spark arrestor screen and retainer, and secure with clamp

Storage General

DANGER: Explosion and Fire. Fuel and vapors are extremely flammable and explosive. Store fuel in a well ventilated area. Keep fire and spark away.

Failure to do so will result in death or serious injury. (000143)

WARNING: Risk of Fire. Verify machine has correctly cooled before installing cover and storing machine. Hot surfaces could result in fire.

It is recommended to start and run the generator for 30 minutes, every 30 days. If this is not possible, see the following list to prepare unit for storage.

DO NOT place a storage cover on a hot generator. Allow unit to cool to room temperature before storage.

DO NOT store fuel from one season to another unless correctly treated.

Replace fuel container if rust is present. Rust in fuel will cause fuel system problems.

Cover unit with a suitable protective, moisture resistant cover.

Store unit in a clean, dry area.

Always store generator and fuel away from heat and ignition sources.

Prepare Fuel System/Engine for Storage

WARNING: Vision Loss. Eye protection is required to avoid spray from spark plug hole when cranking engine. Failure to do so could result in vision loss. (000181)

Fuel stored over 30 days can go bad and damage fuel system components. Keep fuel fresh, use fuel stabilizer.

If fuel stabilizer is added to fuel system, prepare and run engine for long term storage. Run engine for 10-15 minutes to circulate stabilizer throughout fuel system. Adequately prepared fuel can be stored up to 24 months.

NOTE: If fuel has not been treated with fuel stabilizer, it must be drained into an approved container. Run engine until it stops from lack of fuel. Use of fuel stabilizer in fuel storage container is recommended to keep fuel fresh.

Change engine oil.

Remove spark plug.

- Pour 1 tablespoon (5-10cc) of clean engine oil or spray a suitable fogging agent into cylinder.

- Pull starter recoil several times to distribute oil in cylinder.

Install spark plug.

- Pull recoil slowly until resistance is felt. This will close valves so moisture cannot enter engine cylinder. Gently release recoil.

Troubleshooting

Engine won't start.

1. Start Dial turned off.

2. Out of fuel.

3. Faulty spark plug.

4. Plugged fuel filter.

5. Faulty or stuck Start Dial assembly.

6. Incorrect engine oil level.

7. Faulty ignition coil.

8. Carb is flooded.

9. Throttle plate closed.

1. Turn on Start Dial.

2. Fill fuel tank.

3. Replace spark plug.

4. Replace fuel and fuel filter.

5. Contact Customer Service at 1-888- 331-4569.

6. Check/fill engine oil.

7. Contact Customer Service at 1-888- 331-4569.

8. Drain carb.

9. Open throttle plate (push toward back of unit).

Engine starts, then shuts down.

1. Out of fuel.

2. Incorrect engine oil level.

3. Contaminated fuel.

4. Faulty low oil level switch.

1. Fill fuel tank.

2. Check engine oil level.

3. Contact Customer Service at 1-888- 331-4569.

4. Contact Customer Service at 1-888- 331-4569.

Engine will not start; or starts and runs rough.*

1. Choke is stuck or left ON.

2. Dirty or clogged air filter.

3. Faulty or dirty spark plug.

4. Dirty fuel filter.

5. Dirty or gummed up carburetor.

6. Unit not warmed up.

7. Spark arrestor clogged.

1. Turn Start Dial to RUN.

2. Clean or replace air filter

. 3. Replace spark plug.

4. Replace fuel and fuel filter.

5. Clean carburetor.

6. Gradually adjust Start Dial until engine runs smoothly in RUN position.

7. Clean spark arrestor.

No AC output.

1. Generator is overloaded.

2. Inverter module is overheated.

3. Short circuit in electrical device.

4. Faulty inverter assembly

1. Disconnect all loads. Shut down generator to reset module. Reduce loads, restart generator.

2. Verify service door is ON. Let cool 15 minutes by running engine without AC output. Restart genera

3. Verify condition of extension cords and items being powered. Press and hold RESET button on control panel.

4. Contact Customer Service at 1-888- 331-4569.

See other models: CMCBL760E1 CMCBL720M1 CMXGAAM1359134 CMCBL700D1 CMEBL7000