Loading ...

Loading ...

Loading ...

Abluftrohr Ø 120 mm

1. Reduzierstutzen direkt am Luftstutzen befestigen.

2. Abluftrohr am Reduzierstutzen befestigen.

3. Beide Verbindungsstellen geeignet abdichten.

Rohrmaße

Hinweis: Für Beanstandungen, die auf die Rohrstrecke zurück-

zuführen sind, übernimmt der Hersteller des Gerätes keine

Gewährleistung.

■ Das Gerät erreicht seine optimale Leistung durch ein kurzes,

geradliniges Abluftrohr und einen möglichst großen

Rohrdurchmesser.

■ Durch lange raue Abluftrohre, viele Rohrbögen oder

Rohrdurchmesser, die kleiner als 150 mm sind, wird die

optimale Absaugleistung nicht erreicht und das Lüfter-

geräusch wird lauter.

■ Die Rohre oder Schläuche zum Verlegen der Abluftleitung

müssen aus nicht brennbarem Material sein.

Rundrohre

Es wird ein Innendurchmesser von 150 mm empfohlen, jedoch

mindestens 120 mm.

Flachkanäle

Der Innenquerschnitt muss dem Durchmesser der Rundrohre

entsprechen.

Ø 150 mm ca. 177 cm

2

Ø 120 mm ca. 113 cm

2

■ Flachkanäle sollten keine scharfen Umlenkungen haben.

■ Bei abweichenden Rohrdurchmessern Dichtstreifen einsetzen.

Gerät anschließen

Schließen Sie die Muldenlüftung an den Gebläsebaustein oder

das Umluftmodul durch den 6-poligen Stecker an.

en

Ú Installation instructions

Important notes

Read these instructions carefully and keep them in a safe place.

Safety during use can only be ensured if the appliance is fitted

correctly according to these installation instructions. The

installer is responsible for ensuring that the appliance operates

perfectly at the point of installation.

The appliance must be connected to the mains only by a

licensed and trained technician.

Before carrying out any type of work, turn off the electricity.

For installation, currently applicable building regulations and the

regulations of local electricity and gas suppliers must be

observed (e.g. Germany: DVGW-TRGI/TRGF; Switzerland:

SVGW; Austria: ÖVGW-TR).

This appliance corresponds to appliance class 3 (for installation

in a kitchen unit). It must be fitted according to the installation

drawing. Observe the minimum distance to side walls or

furniture parts and to the rear wall.

Safety notes

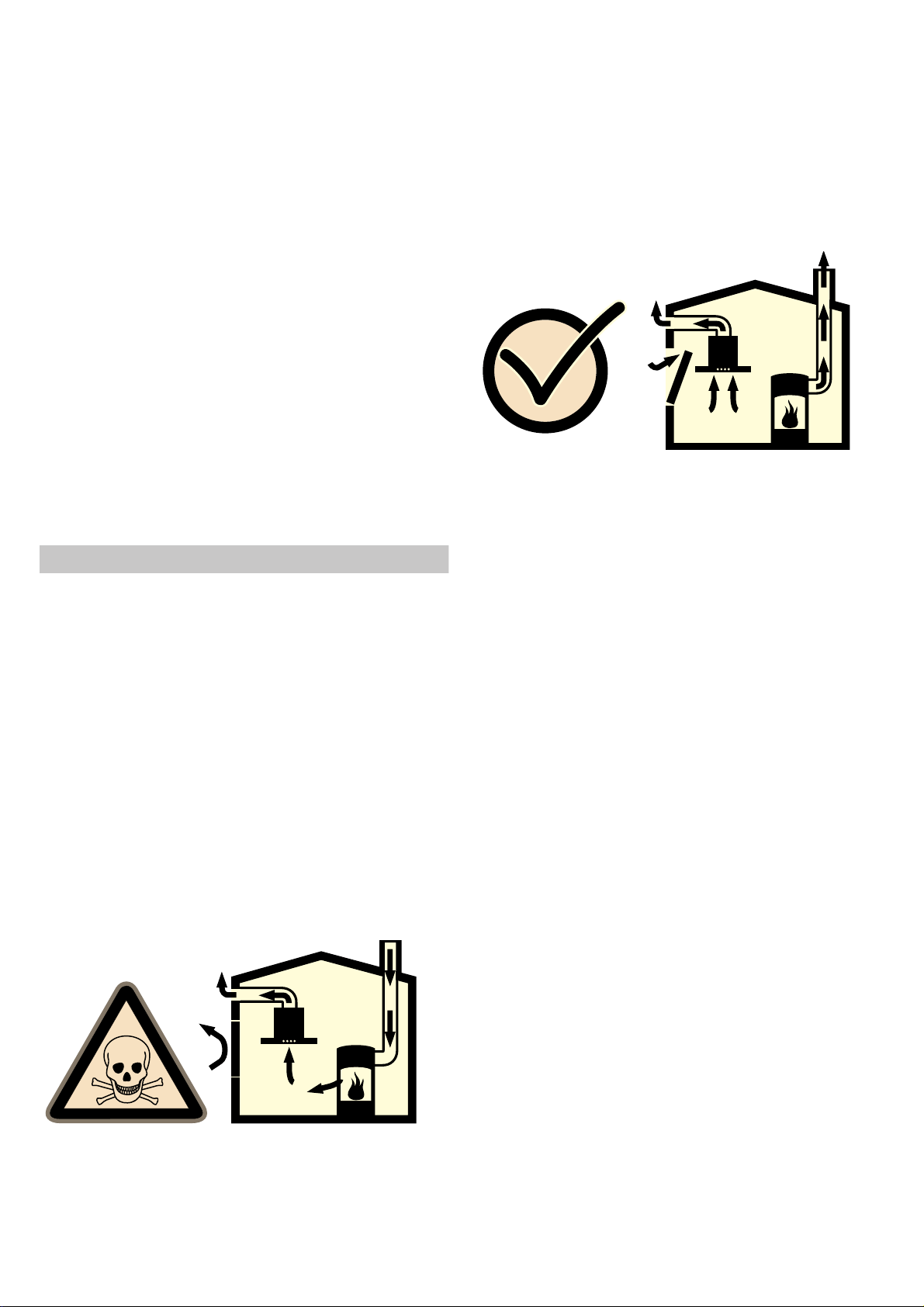

Mortal danger, risk of intoxication!

Due to combustion gases sucked back in. Never operate the

appliance in the exhaust air mode at the same time as a room

air-dependent heat-producing appliance unless an adequate

supply of fresh air is ensured.

Room air-dependent heat-producing appliances (e.g. gas, oil,

wood or coal-operated heaters, continuous flow heaters or water

heaters) obtain combustion air from the room in which they are

installed and discharge the exhaust gases into the open through

an exhaust gas system (e.g. a chimney).

In combination with an activated vapour extractor hood, room air

is extracted from the kitchen and neighbouring rooms - a partial

vacuum is produced if not enough fresh air is supplied. Toxic

gases from the chimney or the extraction shaft are sucked

backed into the living space.

■ Adequate incoming air must therefore always be ensured.

■ An incoming/exhaust air wall box alone will not ensure

compliance with the limit.

Safe operation is possible only whenever the partial vacuum in

the place where the firing equipment is installed does not

exceed 4 Pa (0.04 mbar). This can be achieved whenever the

air needed for combustion is able to enter through openings

that cannot be sealed, for example in doors, windows,

incoming/exhaust air wall boxes or by other technical means.

In any case, consult your responsible chimney sweep. He is

able to assess the house's entire ventilation setup and will

suggest the suitable ventilation measures to you.

Unrestricted operation is possible if the vapour extractor hood is

operated exclusively in the recirculation mode.

Risk of injury!

From sharp edges during installation. Always wear protective

gloves while installing the appliance.

Fire risk!

An air baffle (LS 041 000) must be used if the hob ventilators VL

040/041 are operated next to a gas appliance. In this way, the

flame cannot be drawn into the ventilator. This avoids ignition of

a filter impregnated with grease by the gas flame.

Preparing the furniture

The surrounding kitchen unit must be heat-resistant to at least

90 °C. The stability of the unit must be maintained after

producing the cut-out.

Produce the cut-out for one or several Vario appliances.

Proceed as shown in the installation sketch. The angle between

the cut surface and the worktop must be 90°.

After producing the cut-out, remove the shavings. Seal the cut

surfaces to make them heat-resistant.

Observe a minimum clearance between the appliance housing

and parts of the unit of 10 mm.

When fitting several Vario appliances: allow for the additional

space required for the connecting strip VV 200. Appliances can

also be fitted in individual recesses, if a minimum clearance of

40 mm between the appliances is observed.

Electrical connection

Check the electrical installation system before connecting the

appliance. Make sure that the household installation has

sufficient fuse or circuit breaker protection. Check that the

appliance has the same voltage and frequency as the electrical

installation system (see rating plate).

The appliance corresponds to protection class I and may only

be operated with a protective earth connection.

The installation system must incorporate an all-pole isolating

switch with a contact gap of at least 3 mm, or the appliance

should be connected to the mains via a safety plug. The plug

must remain accessible after installation.

Recommendation: install a properly earthed socket behind the

appliance, approx. 70 cm above the floor.

Only a qualified electrician who takes the appropriate

regulations into account may connect a socket.

Only connect the appliance with the supplied mains connection

cable.

Do not kink or trap the mains connection cable.

The appliance corresponds to type Y: the mains connection

cable must only be replaced by the after-sales service. Check

the cable type and minimum cross section.

Loading ...

Loading ...

Loading ...