Loading ...

Loading ...

Loading ...

Cable Handling Guide

Cable Terminations, Tensioning and Wear Guide

Cable Connections with threaded cable ends are required to be installed and maintained following the specifications identified below.

Failure to follow these specifications can lead to the dislocation of the threaded cable during use and can cause serious injury. Along

with securing the threaded cable end and jam nut, it is important to check the entire unit and ensure that all hardware is securely

fastened and not loose upon completion of cable installation.

WARNING: Use of non certified “techs” note: Service warranties may be void if a non-Cybex-certified technician performs

service work. Replacement of any strength cables should be performed by a Cybex certified technician.

Cable Terminations

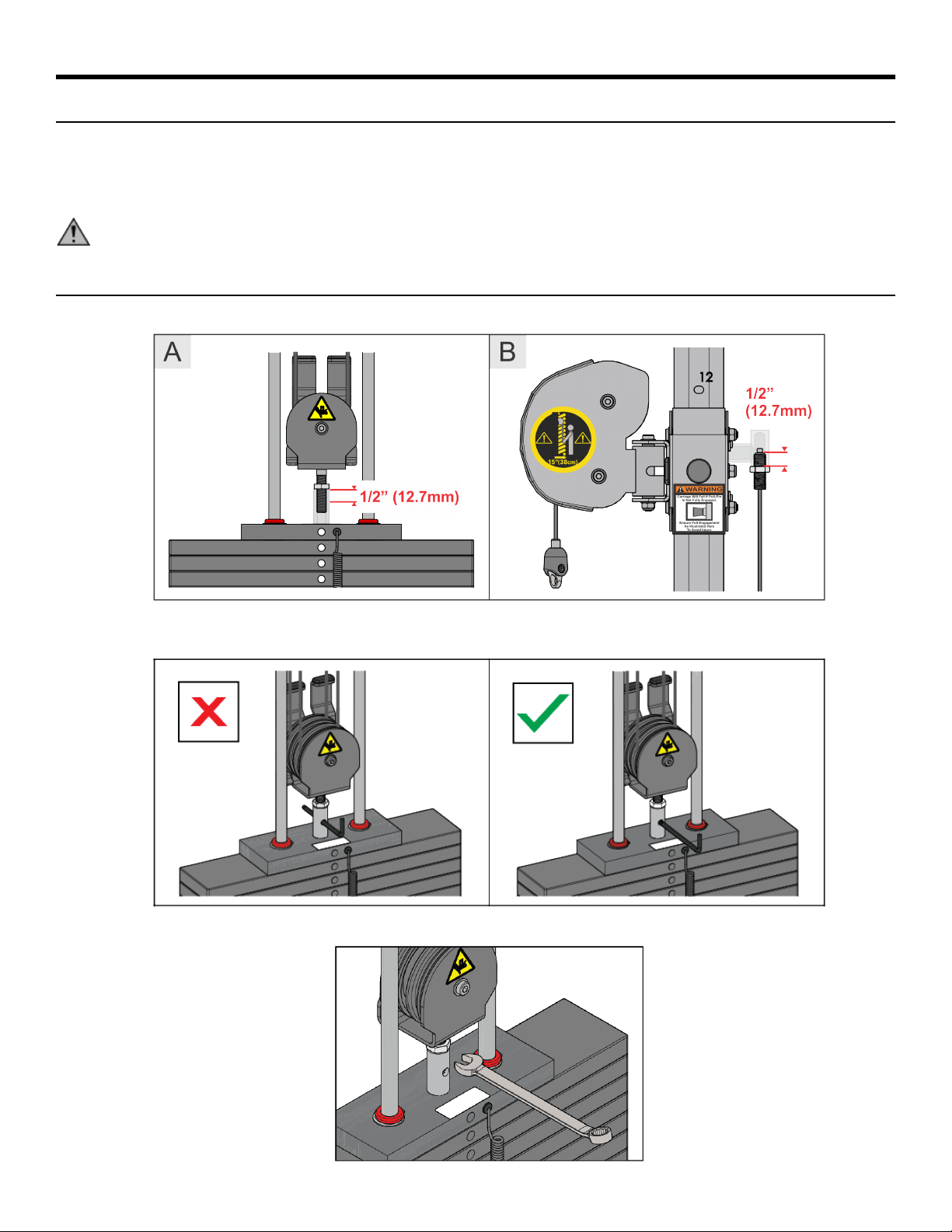

1. Cable must be threaded at least ½ inch (12.7mm) into termination points; at headplate (A) and frame/carriage (B).

2. Certain models are now equipped with a bayonet portal to assist checking proper thread engagement. To do so, attempt to pass a

7mm Allen wrench through the portal, if it goes through, more threads are needed to meet the minimum requirement.

3. When proper thread engagement is reached, tighten jam nut to 20-25 FT-LBS (27.2 - 34.0 Nm) using a 24mm wrench.

Page 26 of 34

Loading ...

Loading ...

Loading ...