Loading ...

Loading ...

Loading ...

NOTICE: This device complies with Part 15 of the FCC rules and

Industry Canada’s license-exempt RSSs. Operation is subject to the

following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Any changes or modifi cations not expressly approved by the party

responsible for compliance could void the user’s authority to operate

the equipment.

This device has been tested and found to comply with the limits for

a Class B digital device, pursuant to part 15 of the FCC rules and

Industry Canada ICES standard. These limits are designed to provide

reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

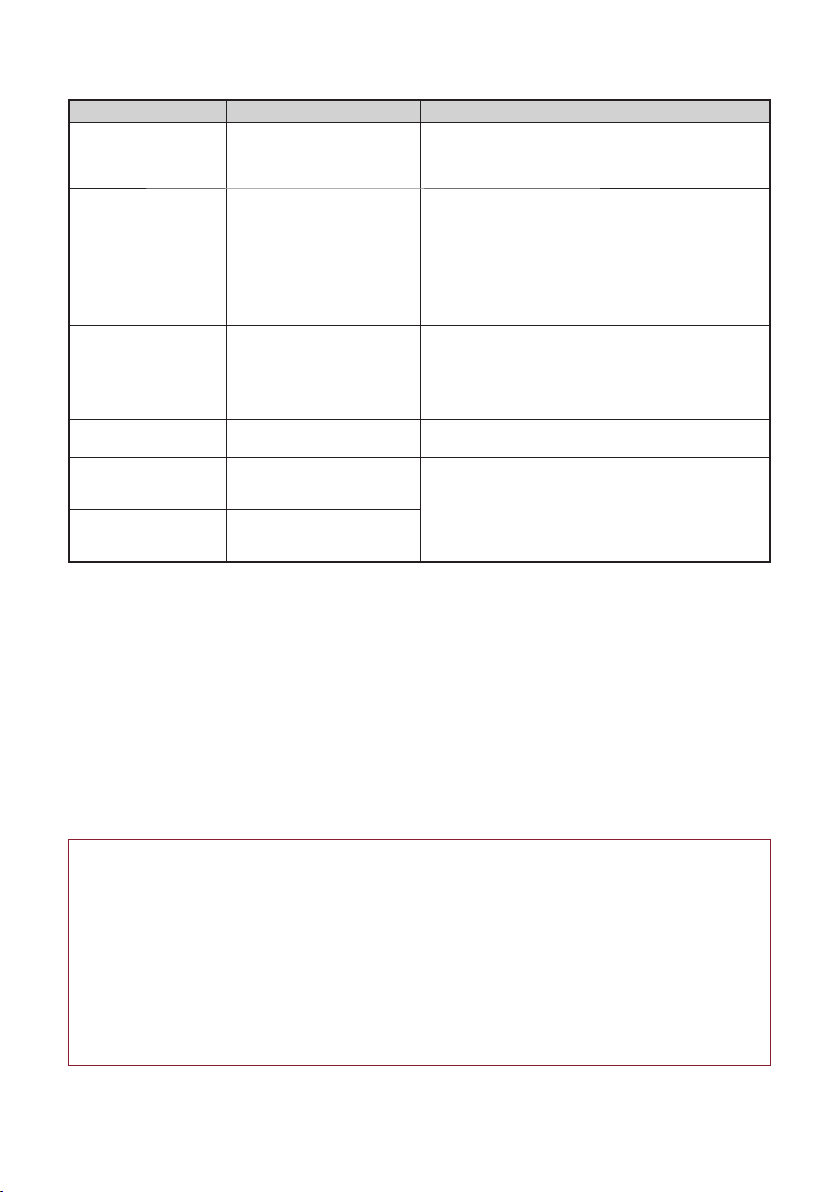

Troubleshooting

Symptom Possible Cause Solution

Gate does not move 1. Minimum number of

entrapment protection

devices not installed

2. Sensors are obstructed

1. Review sensor connections. Slide gate operators require

a minimum of two external monitored devices; one in the

close and one in the open direction.

2. Check for obstructions.

RECEIVER:

Solid Red LED

1. Sensors are not aligned

2. Sensors are too far apart

3. Sensor lenses are dirty

4. Object is obstructing beam

5. Condensation on sensor

lenses

6. Sensor has adapted to short

range use but is installed in a

long range application.

1. Align the sensors until the blue light is solid

2. Decrease the distance between the sensors. NOTE:

Sensors must be 3 ft. (.9 m) - 90 ft. (27.4 m) apart.

3. Gently clean the sensors with a soft damp towel

4. Remove any objects obstructing beam

5. Gently clean the sensors with a soft towel; make sure

sensor heaters are connected.

6. Follow the instructions in the Reset Range Mode section

to reset sensor.

RECEIVER:

Blinking Blue LED

1. Sensors are not optimally

aligned

2. Sensors are too far apart or

too close together

3. Sensor lenses are dirty

1. Align the sensors until the blue light on the receiver is

solid

2. Adjust the distance between the emitter and receiver.

NOTE: Sensors must be 3 ft. (.9 m) - 90 ft. (27.4 m)

apart.

3. Gently clean the sensors with a soft damp towel

EMITTER and RECEIVER:

Blinking Red LED

Incorrect wiring Check for proper connection of sensor wiring. If the issue

continues, replace sensor.

EMITTER or RECEIVER:

Red/Blue LEDs blinking

together

Internal memory fault

Disconnect all power, wait 15 seconds, then reconnect

power. If issue continues, replace sensor.

EMITTER or RECEIVER:

Red/Blue LEDs alternate

blinking

Internal fault

Accessories

LMSGBP: Photoelectric sensor gang box plate

LMEHUL: Photoelectric sensor extended hood further enhances reliability in extreme weather conditions

APOW1: Plug in transformer

Warranty

LiftMaster

®

warrants to the fi rst consumer purchaser of this product that it is free from defect in materials and/

or workmanship for a period of 2 years from the date of purchase.

Loading ...

Loading ...

Loading ...