Loading ...

Loading ...

Loading ...

NEVER LEAVE HEATER UNATTENDED WHILE BURNING

OR WHILE CONNECTED TO A POWER SOURCE

© 2017, Pinnacle Climate Technologies, Inc. Kerosene Forced Air Heater User’s Manual

®

Maintenance

Service:

DO NOT TAMPER WITH THE UNIT. HAVE

A COMPETENT SERVICEMAN MAKE ANY

NECESSARY ADJUSTMENT OR REPAIRS.

Use only original equipment parts. The use of alternate

or third party components can cause unsafe operating

conditions and will void your warranty.

We suggest following a maintenance schedule as follows:

FUEL / FUEL TANK:

Flush tank every 200 hours of operation or as needed.

DO NOT ush with water; use fresh K-1 kerosene only.

AIR FILTERS:

The air intake lter should be replaced or washed with

soap and water and dried thoroughly every 500 hours

of operation or less depending on conditions.

The output and lint lters should be replaced

every 500 hours of operation or less depending on

conditions. (See Figure 4)

NOTE: Use of diesel fuel may require additional

maintenance

FAN BLADES:

Blades should be cleaned at least once per heating

season, depending on conditions. Remove all

accumulated dust and dirt with a damp cloth, taking

care not to bend any of the fan blades. Be sure the

blades are dry before re-starting the heater.

FUEL FILTER:

The fuel filter should be cleaned at least twice

per heating season. Clean the filter by rinsing

it in clean K-1 Kerosene. Contaminated fuel

could make cleaning the fuel filter necessary

immediately.

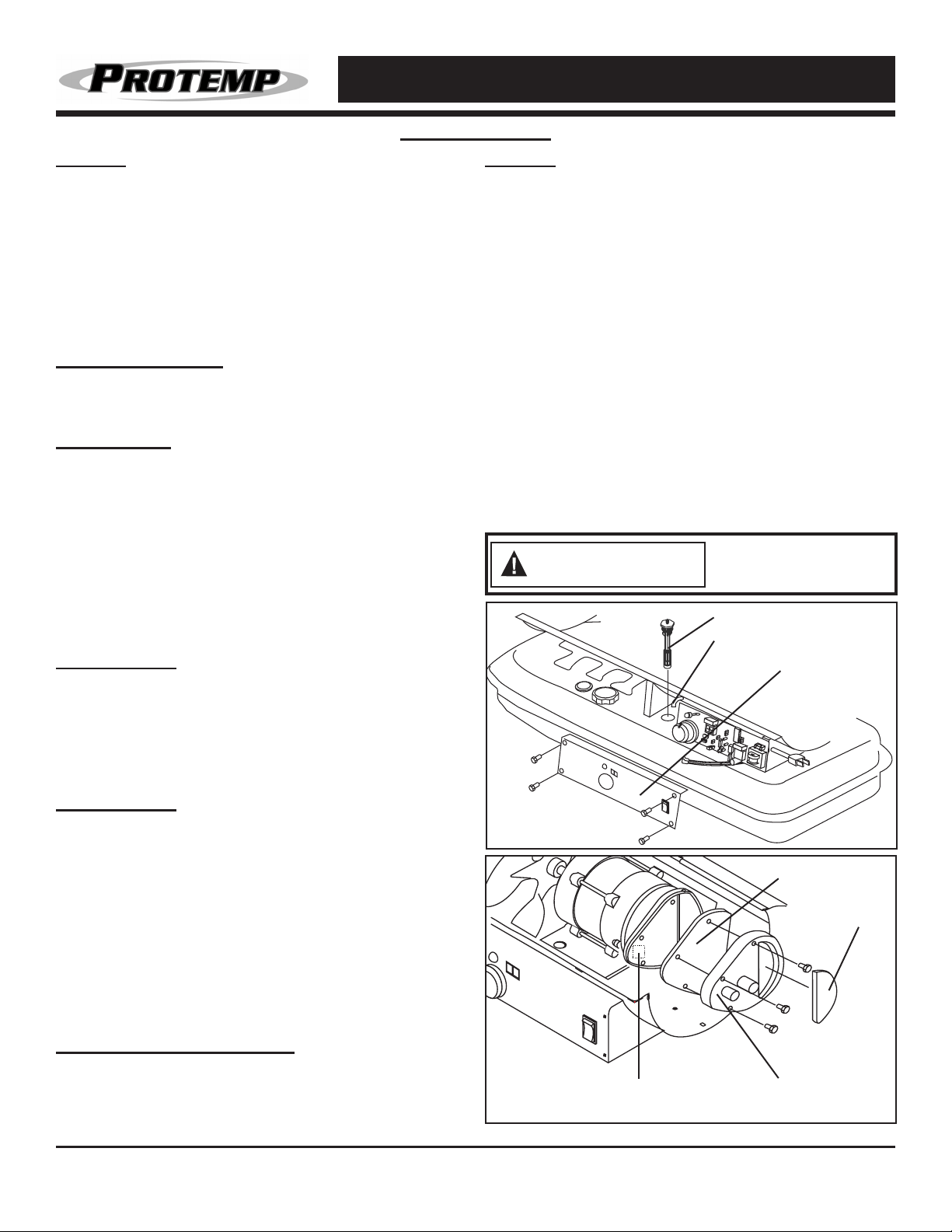

NOTE: To remove the filter from models 45/75T-

KFA turn filter 90º clockwise. To remove the

filter from models 125T - 215T-KFA turn filter 90º

counter-clockwise. See Figure 3.

THERMISTER PLACEMENT:

Ensure the thermister wire is in the proper place.

The wire should be lying on the bottom shell inside

the heater with the plastic end placed under the

motor support/motor and away from fan blade.

ROTOR:

The rotor with carbon vanes should be evaluated

every heating season. The rotor is behind the air

filters. The vanes should be inspected for damage

or wear. The rotor should be inspected for damage,

chips, wear, cracks.

Check rotor gap: Remove the rear cover.

Loosen the two pump ring screws. Lift the pump

ring upwards. Insert a 0.1 mm feeler gauge and

apply slight downward pressure, enough to offer

resistance when attempting to remove gauge.

Hand-tighten the two pump ring screws. Re-install

the End Pump Cover and the plastic End Filter

Cover. Start the heater and adjust to the proper

pump pressure.

Air Output Filter

Intake Filter

Lint Filter End Filter

Figure 4

7

Never service

heater while it is

plugged in or hot!

WARNING

Figure 3

Fuel Filter

Fuel Line

Side Cover

Loading ...

Loading ...

Loading ...