Loading ...

Loading ...

Loading ...

www.BISSELL.com

14

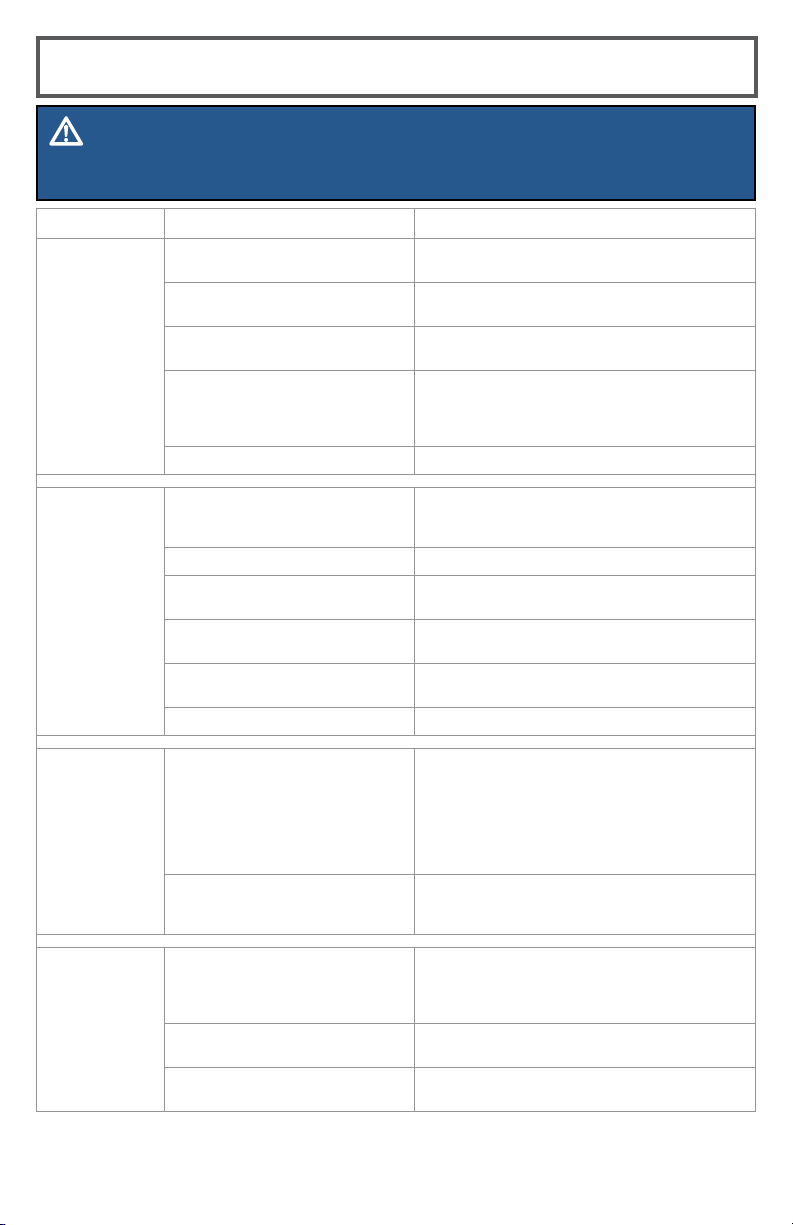

Troubleshooting

WARNING

To reduce the risk of electric shock, turn power switch o and disconnect from electrical

outlet before performing maintenance or troubleshooting checks.

Problem Possible causes Remedies

Reduced spray

or

no spray

Spray nozzle clogged. Clean spray nozzle using an unfolded paper

clip.

Clean water/solution tank

empty.

Check/fill tank.

Clean water/solution tank insert

clogged.

Clean insert at bottom of clean water/solution

tank.

Pump needs priming. Gently lift clean water/solution tank while

depressing the spray trigger OR gently

squeeze clean tank while depressing spray

trigger.

Clean tank not fully seated. Remove and reinstall clean tank.

Spot cleaner

won’t pick

up cleaning

solution

Poor upholstery/carpet

tool position.

Reposition upholstery/carpet tool

on surface, follow recommended cleaning

procedures.

Dirty water tank is full. Empty dirty water tank.

Excess solution in flex hose. Lift tool and point upwards to allow water in

hose to flow into the dirty water tank.

Incorrect cleaning formula. Use BISSELL 2X Portable Machine formulas

only.

Dirty tank is improperly seated

onto base.

Remove dirty tank and reseat onto unit.

Dirty tank plug is unplugged. Push in dirty tank plug until properly sealed.

Deep Stain

Tool is

Over-Spraying

Formula

(Formula is

Spraying

Out the Sides)

Formula trigger is being pulled

when tool is above carpeting.

Make sure the Deep Stain Tool’s formula

injection needles are burrowed deeply within

your carpeting before pressing the formula

spray trigger. To avoid over-spraying, make

sure the tool stays in direct contact with the

carpet at all times.

Deep Stain Tool is being used

on upholstery.

The Deep Stain Tool is designed for high-pile

carpets and rugs. Switch to the 3” Tough

Stain Tool for upholstery cleaning.

Dirty Water

Tank Leaking

Duckbill valve is dirty. Clean the duckbill valve that is located at

the bottom of the dirty water tank. Once

cleaned, make sure it is placed securely

back in place.

Float stack not fully locked on

dirty tank.

Remove float stack and twist until arrow is

aligned with lock symbol on dirty tank pg. 12.

Dirty tank not properly seated

onto machine.

Remove and reseat onto unit.

Loading ...

Loading ...

Loading ...