Loading ...

Loading ...

Loading ...

R600 and HSRL Series LP-Gas Regulators

6

Indoor Installations

By code, regulators installed indoors have limited inlet

pressure and they require a vent line to the outside of the

building, see Figure 4. A vent assembly, such as

Fisher

®

Y602 Series, should be used on the end of the vent

line. The same installation precautions, previously discussed

throughout this manual for the regulator vent, apply to the

end of the vent tube assembly. Vent lines must not restrict

the gas flow from the regulator’s internal relief valve. Vent

lines should be at least 3/4 in. NPT pipe or 3/4 in. NPT size

PVC Schedule 40 Rigid Conduit, meeting the requirements

of Underwriters Laboratories (UL

®

) 651. To install the vent

line, remove the vent screen and apply a good grade of pipe

dope to the male threads of the line. Vent lines should be as

straight as possible with a minimum number of bends.

Underground Installations

!

WARNING

Types R632A and R632E integral regulators

require 2 vent tubes, one on the first stage

vent and one on the second stage vent, when

installed on underground tanks. Failure to

use 2 separate vent tubes can result in early

regulator failure and/or over pressuring the

second stage that could result in fires or

personal injury.

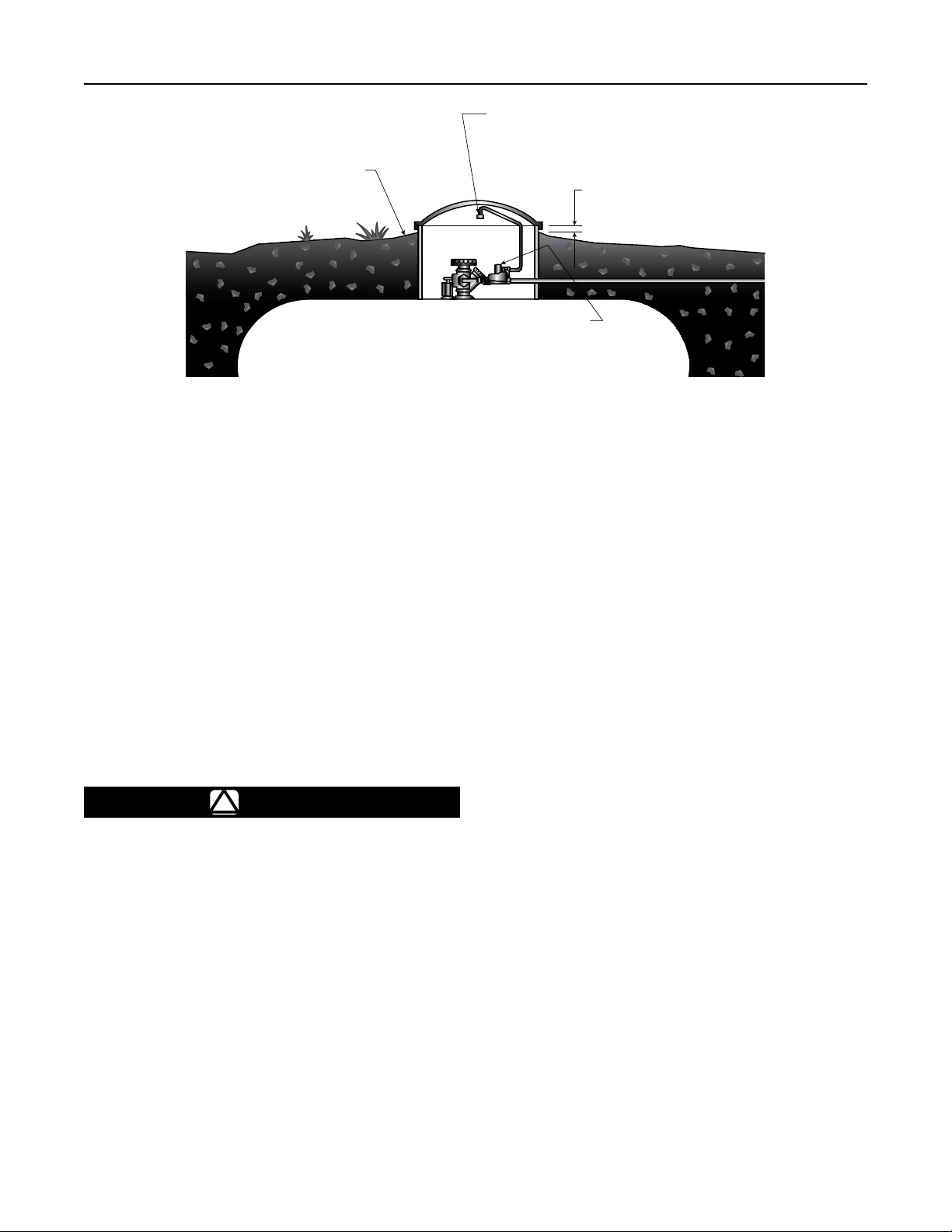

Regulators installed in the dome of an underground

container require a vent tube to prevent water from entering

the regulator spring case, see Figure 5.

Note

Types R632A and R632E integral regulators

installed on underground tanks require the

use of 2 vent tubes, one for the first stage

vent (1/4 in. OD copper tube inverted flare

connection: 7/16-24 UN thread) and the other

for the second stage vent (3/4 in. NPT) of

the regulator.

Remove the vent screens and install vent tubes. The vent

tube must be run from the regulator vent to above the

maximum water table. The vent tube opening must terminate

at the extreme top inside of the dome cover. Make sure the

regulator’s closing cap is on tightly, and maintain drainage

away from the dome at all times.

Outdoor Installations with Underground

Vent Lines

When installed per code, the underground vent line must not

restrict the gas flow from the regulator’s internal relief valve

and must remain clear of debris, dry and fully open at all

times. Joints in the vent line must be fully sealed to prevent

moisture intrusion into the vent line. A vent assembly, such

as the Fisher Y602 Series, should be used on the end of

the vent line to prevent entry of precipitation, water or other

debris. When underground vent lines are used in humid

environments, the vent line must be designed to allow for

proper drainage of any collected moisture or condensation.

Adjustment

Each regulator is factory set. If it becomes necessary to

increase the outlet pressure, remove the closing cap and

turn the adjustment screw clockwise. Turn the adjusting

screw counterclockwise to decrease the outlet pressure. The

first stage portion of the Types R632A and R632E integral

regulators is non-adjustable.

WATER MARK LEFT IN HOUSING DOME AT LEVEL ABOVE REGULATOR VENT OR END OF

VENT TUBE REQUIRES REPLACEMENT OF REGULATOR. INSTALL REGULATOR PROPERLY.

Figure 5. Underground Installation

GRADE GROUND DOWNWARD AND

SLOPING AWAY FROM HOUSING DOME.

THIS PREVENTS WATER COLLECTING

AND RUNNING INTO OR STANDING

AROUND HOUSING DOME.

END OF REGULATOR VENT

TUBE LOCATED AT TOP INSIDE

OF HOUSING DOME COVER

2 in. / 5.1 cm

MINIMUM

REGULATOR ADJUSTMENT

CLOSURE CAP MUST BE TIGHT.

T14448-A2

Loading ...

Loading ...