Loading ...

Loading ...

R600 and HSRL Series LP-Gas Regulators

3

TYPE

TYPICAL SETPOINT

NOMINAL RELIEF VALVE

START-TO-DISCHARGE

MAXIMUM INLET PRESSURE TO NOT EXCEED

OUTLET PRESSURE WITH DISC REMOVED

Inlet Pressure Maximum Outlet Pressure

psig bar psig bar psig bar psig bar

HSRL

11 in. w.c. 27 mbar 1 69 mbar

15 1.0

2 0.14

R622 and R642

50 3.4

R652

R632A

(1)

250 17.2

R632E

(1)

2 0.14 3.5 0.24

250 17.2

5 0.34R622E

50 3.4

R652E

R622H 10 0.69 20 1.37 Not Applicable

1. For integral two-stage regulators, the second stage disc is removed.

Table 1. Relief Valve Specifications

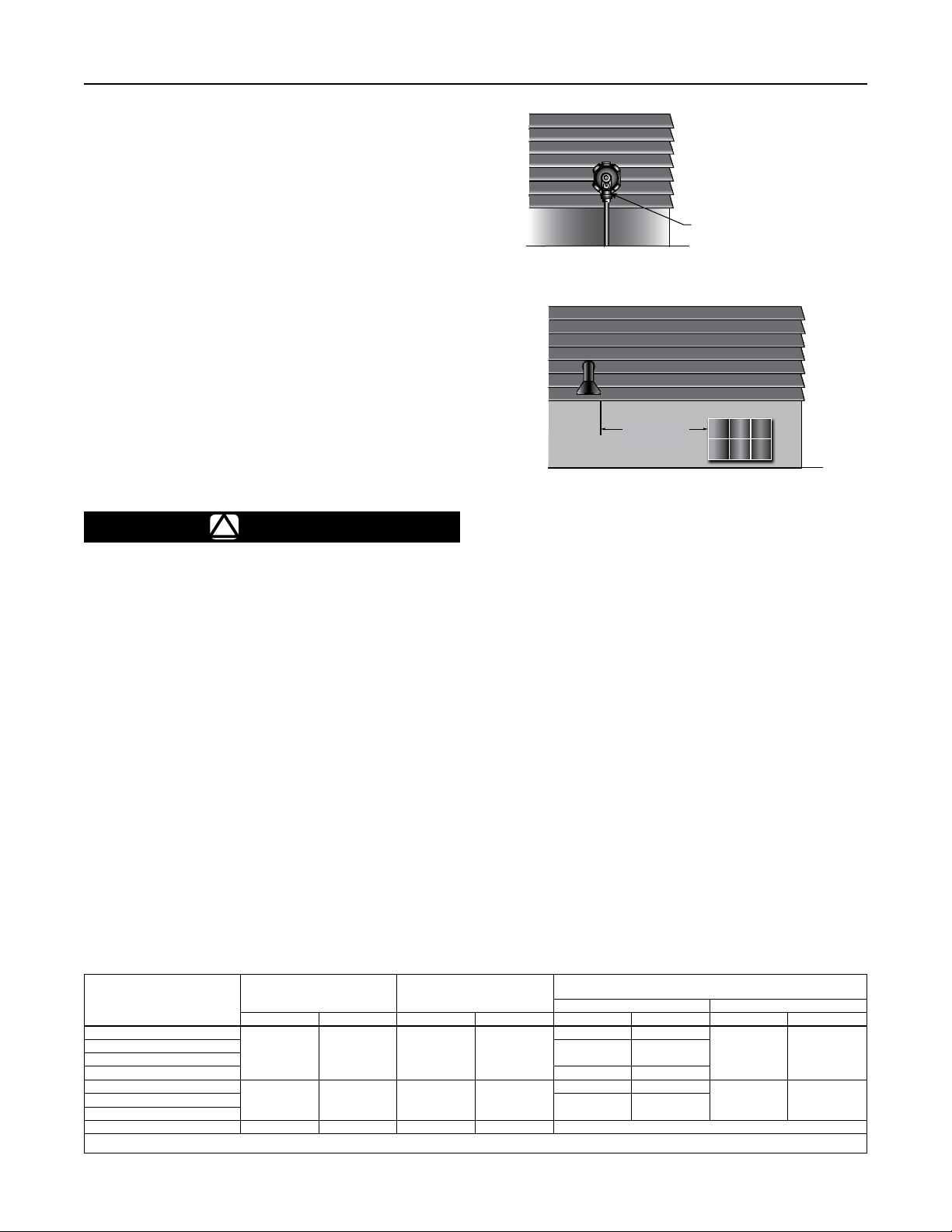

Figure 2. Regulator with Vent Pointed Down

3

3 FT /

0.91 m

VENT POINTED DOWN

Integral Two-stage Regulator

The Type R632A integral two-stage regulator contains a

non-adjustable first stage regulator on the inlet. The second

stage provides 11 in. w.c. / 27 mbar outlet pressure. The

second stage portion has a high capacity internal relief valve

construction. The first stage does not have an internal relief

valve. The regulators are normally painted GRAY with a

BLACK CAP.

Integral Two psig Service Regulator

The Type R632E integral two psig service regulator contains

a non-adjustable first stage regulator on the inlet. The

second stage provides 2 psig / 0.14 bar outlet pressure. The

second stage portion has a high capacity internal relief valve

construction. The first stage does not have an internal relief

valve. The regulators are normally painted GRAY with a

WHITE CAP and White 2-psig STICKER.

Installation

!

WARNING

All vents should be kept open to permit free

flow of air in and out of the regulator. Protect

vent openings against the entrance of rain,

snow, ice formation, paint, mud, insects,

water from an irrigation system or any other

foreign material that could plug the vent or

vent line or accumulate in the vent line.

LP-Gas may discharge to the atmosphere

through the vent. An obstructed vent which

limits air or gas flow can cause abnormally

high pressure that could result in personal

injury or property damage. Failure to use a

vent line on Indoor Installations can cause a

hazardous accumulation of gas which could

result in personal injury or property damage.

Types R622H, R622E, R632A, R632E and

R652E regulators are not suitable for

indoor installations.

Never use a Type R622H, R622E, R632E or

R652E (pounds-to-pounds) regulator on low

pressure (inches of water column) service

because personal injury or property damage

could occur. The Types R622E and R652E are

not suitable for use as a “first stage” regulator.

General Installation Instructions

Before installing the regulator,

• Check for damage, which might have occurred

in shipment.

• Check for and remove any dirt or foreign material, which

may have accumulated in the regulator body.

• Replace old pigtails. Blow out any debris, dirt or copper

sulfate in the copper tubing and the pipeline.

• Apply pipe compound to the male threads of the pipe

before installing the regulator.

• Make sure gas flow through the regulator is in the same

direction as the arrow on the body. “Inlet” and “Outlet”

connections are clearly marked.

T14446-A2

Loading ...

Loading ...

Loading ...