Loading ...

Loading ...

Loading ...

2.3 Battery Connection

2.3.1 Battery Power Cable Connection

Note: for lead acid battery, the recommended charge current is 0.2C( C to battery capacity)

1. Please follow below steps to implement battery connection:

2. Assemble battery ring terminal based on recommended battery cable and terminal size.

3. Connect all battery packs as units requires. It's suggested to connect at least 200Ah capacity battery

for SNA5000 WPV.

4. Insert the ring terminal of battery cable flatly into battery connector of inverter and make sure the bolts

are tightened with torque of 2 ~3Nm. Make sure polarity of the battery is correctly connected and ring

terminals are tightly screwed to the battery terminals.

2.3.2 Lithium Battery Connection

If choosing lithium battery for SNA5000 WPV, please make sure the battery BMS is compatible with

Luxpower inverter. Please check the compatible list in the Luxpower website.

Please follow below steps to implement lithium battery connection:

1. Connect power cable between inverter and battery

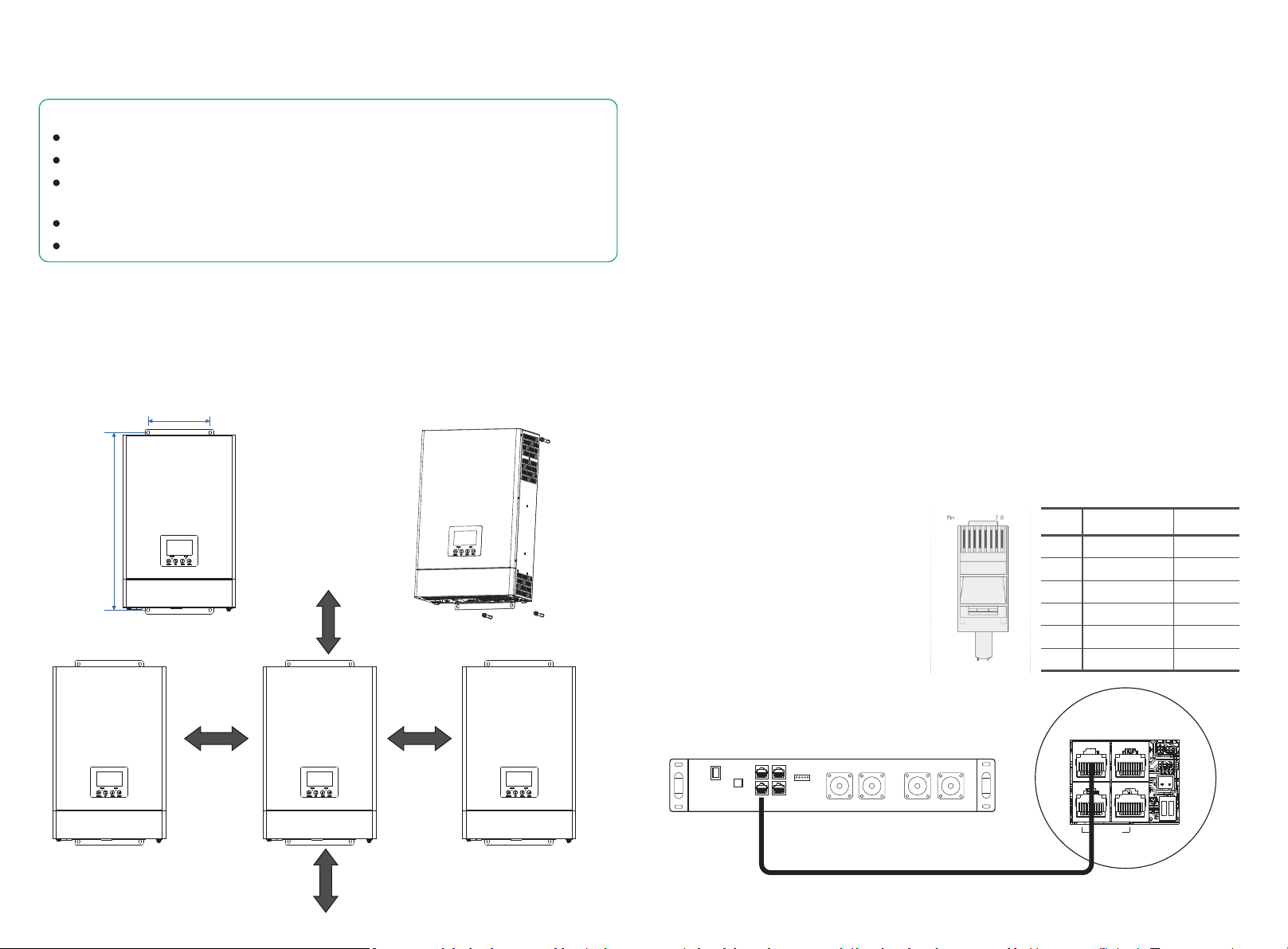

2. Connect the CAN or RS485 communication cable between inverter and battery. If you do not get

the communication cable from inverter manufacturer or battery manufacturer, please make the cable

according to the PIN definition

3. Lithium battery configuration, in order to

communicate with battery BMS, you should

set the battery type to “Li-ion” in Program

“03” by LCD and choose the right battery

brand (for details, please check the LCD

setting chapter), users can also choose the

battery type and brand by monitor system.

Pin

1 2

3

4

5

6 7 8

Pin

1

2

3

4

RS 485B

CANL

CANH

5/6

RS 485 port CAN port

RS 485A

7/8

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

07

08

1

2

3 4

5

6

MPPT485

NTC

Parallel

Battery Pack

Inverter

2.2 Mounting the Unit

Consider the following points before selecting where to install:

Mount on a solid surface

Do not mount the inverter on flammable construction materials.

For proper air circulation to dissipate heat, allow a clearance of approx. 20 cm to the side and approx.

50 cm above and below the unit.

The ambient temperature should be between 0°C and 55°C to ensure optimal operation.

The recommended installation position is to be adhered to the wall vertically.

180 mm

519 mm

Step1. Use the wall-mounting bracket as the template to mark the position of the 4 holes, then drill 8 mm

holes and make sure the depth of the holes is deeper than 50mm.

Step2. Install the expansion tubes into the holes and tight them, then use the expansion screws (packaged

together with the expansion tubes) to install and fix the wall-mounting bracket on the wall.

Step3. Install the inverter on the wall-mounting bracket and lock the inverter using the security screws.

200mm 200mm

500mm

500mm

Steps to mounting the unit

Notice:

Loading ...

Loading ...

Loading ...