Loading ...

Loading ...

Loading ...

Installing the water heater.

12

!

WARNING:

Never use an open

flame to test for gas

leaks, as bodily

injury, property

damage or death

could result.

Leak Testing

The water heater and its gas connections must

be leak tested at normal operating pressures

before it is placed in operation.

Turn on the manual gas shut-off valve

near the water heater.

Use a soapy water solution to test for

leaks at all connections and fittings.

Bubbles indicate a gas leak that must be

corrected.

The factory connections to the gas control

(thermostat) should also be leak tested after the

water heater is placed in operation.

Pressure Testing the Gas Supply System

The water heater and its manual gas shut-

off valve must be disconnected from the gas

supply piping system during any high pressure

testing of that system at pressures in excess of

1/2 psi (14” w.c.).

The water heater must be isolated from the gas

piping system by closing the manual gas shut-

off valve during any pressure testing of the gas

supply piping at pressures equal to or less than

1/2 psi (14” w.c).

High Altitude

Ratings of gas appliances are based

on sea level operation and need not be

changed for installations at elevations up to

7,700 feet.

For installations above 7,700 feet, Please

contact your local distributor or place of

purchase for a high altitude model.

WARNING: Failure to install a water heater

suitable for the altitude at the location it is

intended to serve, can result in improper

operation of the appliance resulting in property

damage and/or, producing carbon monoxide

gas, which could result in personal injury, or

death.

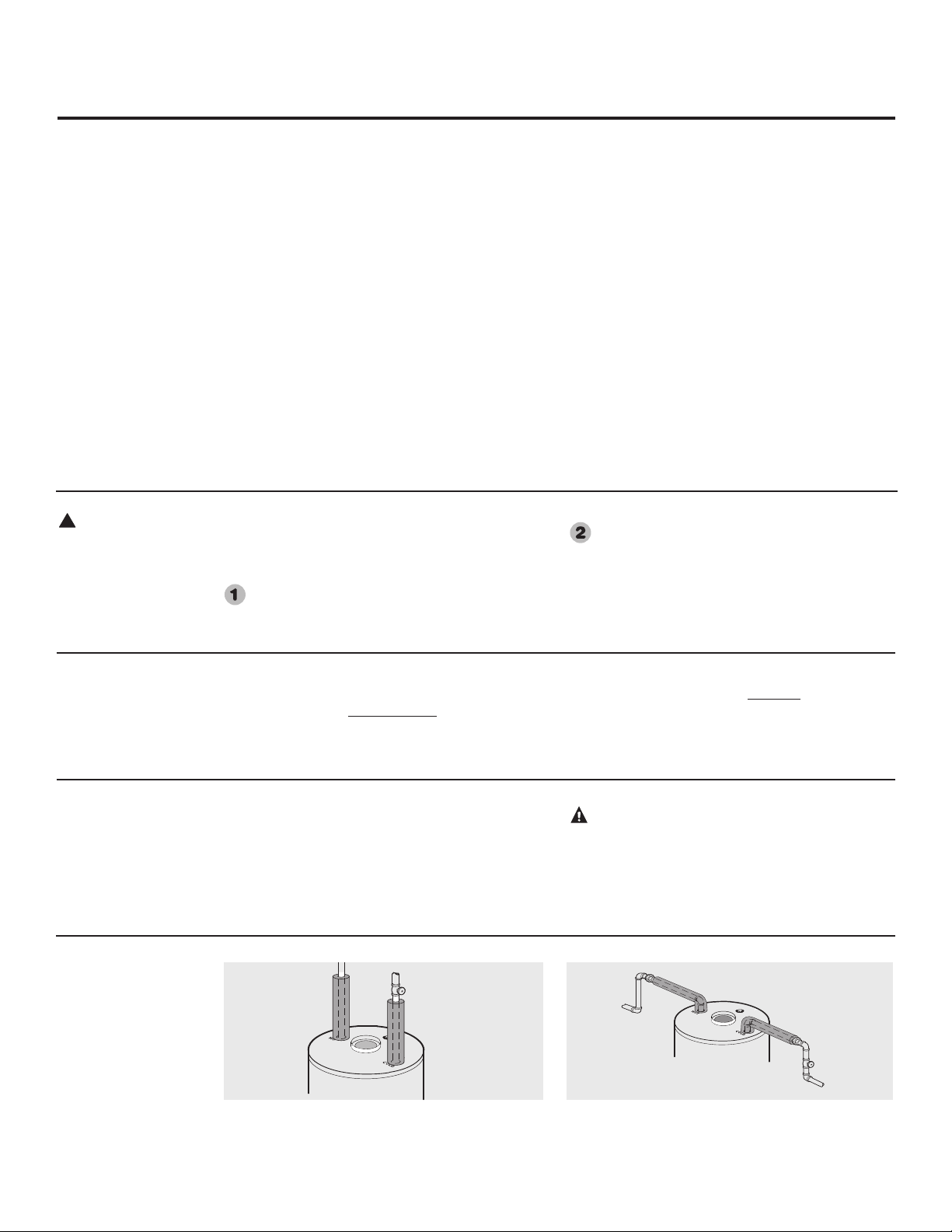

For increased energy efficiency, some water

heaters have been supplied with two 24”

sections of pipe insulation.

Please install the insulation, according to

the illustrations above, that best meets your

requirements.

Typical vertical piping arrangement

Typical horizontal piping arrangement

Hot and Cold Pipe Insulation Installation

Gas Supply

Check the markings on the water heater’s rating plate to

be certain the type of gas being furnished corresponds to

that for which the water heater is built. The water heater

can be converted from natural gas to LP or vice versa.

See the Conversion Instructions section of this manual.

The branch gas supply line to the water heater should be

clean 1/2” black steel pipe or other approved gas piping

material.

A ground joint union or ANSI design certified semi-rigid

or flexible gas appliance connector should be installed

in the gas line close to the water heater. The HUD code

should be followed for installation and location of a

manual shutoff valve. If lever type gas shut-offs are used,

they shall be T-Handle type.

Compound used on the threaded joints of the gas piping

must be of the type resistant to the action of LP gas. Use

compound sparingly on male threads only.

Where a sediment trap is not incorporated as part of the

appliance, a sediment trap shall be installed downstream

of the equipment shutoff valve as close to the inlet of

the appliance as practical at the time of the appliance

installation. The sediment trap shall be either a tee fitting

with a capped nipple in the bottom outlet or other device

recognized as an effective sediment trap. Do not use

excessive force (over 31.5 ft lbs.) in tightening the pipe

joint at the thermostat inlet, particularly if teflon pipe

compound is used, as the valve body may be damaged.

The inlet gas pressure to the water heater must not

exceed 14” w.c. for natural or LP gas. For purposes of

input adjustment, the minimum inlet gas pressure (with

main burner on) is shown on the water heater rating plate.

If high or low gas pressures are present, contact your gas

supplier for correction.

If flexible connectors are used, the maximum length shall

not exceed 36” (91 cm).

Loading ...

Loading ...

Loading ...