Loading ...

Loading ...

Loading ...

13

5. Installing the unit

5.1. Hanging the unit body

Bring the indoor unit to an installation site as it is packed.

To hang the indoor unit, use a lifting machine to lift and pass through the

hanging bolts.

[Fig. 5-1-1] (P.3)

[Fig. 5-1-2] (P.3)

5.2. Confirming the unit’s position and fixing hanging

bolts

Ensure that the hanging bolt nuts are tightened to fix the hanging bolts.

To ensure that drain is discharged, be sure to hang the unit at level using a

level.

Caution:

Install the unit in horizontal position. If the side with drain port is installed

higher, water leakage may be caused.

6. Refrigerant piping work

6.1. Refrigerant pipe

[Fig. 6-1-1] (P.3)

Refer to the Instruction Manual that came with the outdoor unit for the restrictions on

the height difference between units and for the amount of additional refrigerant

charge.

Avoid the following places for installation where air conditioner trouble is liable to occur.

• Where there is too much oil such as for machine or cooking.

• Salty environment as seaside areas.

• Hot-spring areas.

• Where sulfide gas exists.

• Other special atmospheric areas.

• This unit has flared connections on both indoor and outdoor sides. [Fig. 6-1-1]

• Refrigerant pipes are used to connect the indoor and outdoor units as shown in the

figure below.

• Insulate both refrigerant and drainage piping completely to prevent condensation.

Piping preparation

• Refrigerant pipes of 3, 5, 7, 10 and 15 m [9-13/16, 16-3/8, 22-15/16, 32-1/4 and

49-3/16 ft] are available as optional items.

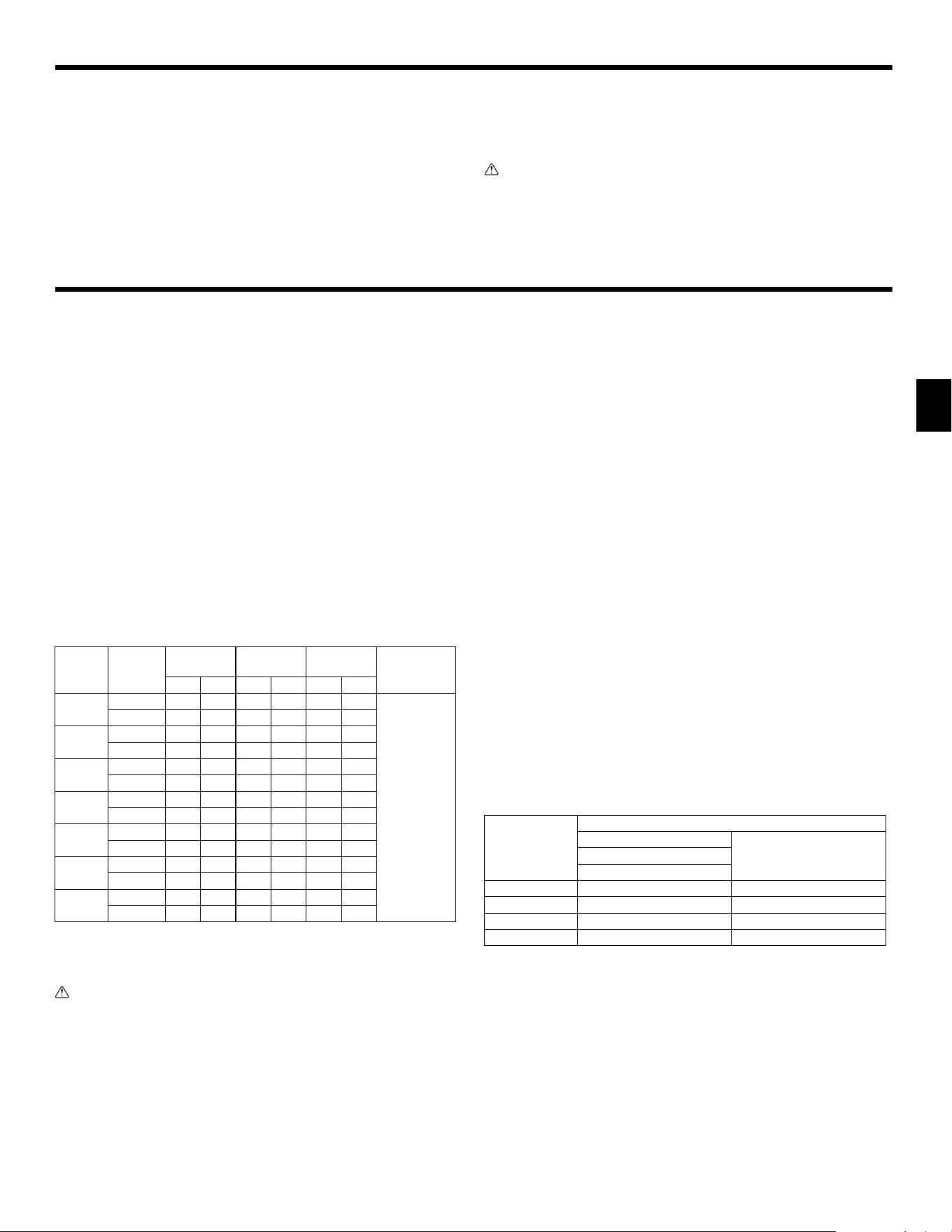

(1)Table below shows the specifications of pipes commercially available.

(2)Ensure that the 2 refrigerant pipes are well insulated to prevent condensation.

(3)Refrigerant pipe bending radius must be 10 cm [3-15/16 in] or more.

Caution:

Using careful insulation of specified thickness. Excessive thickness prevents

storage behind the indoor unit and smaller thickness causes dew drippage.

6.2. Flaring work

• Main cause of gas leakage is defect in flaring work.

Carry out correct flaring work in the following procedure.

6.2.1. Pipe cutting

[Fig. 6-2-1] (P.4)

• Using a pipe cutter cut the copper tube correctly.

6.2.2. Burrs removal

[Fig. 6-2-2] (P.4)

• Completely remove all burrs from the cut cross section of pipe/tube.

• Put the end of the copper tube/pipe to downward direction as you remove burrs in

order to avoid burrs drop in the tubing.

6.2.3. Putting nut on

[Fig. 6-2-3] (P.4)

• Remove flare nuts attached to indoor and outdoor unit, then put them on pipe/tube

having completed burr removal.

(not possible to put them on after flaring work)

6.2.4. Flaring work

[Fig. 6-2-4] (P.4)

• Carry out flaring work using flaring tool as shown below.

Firmly hold copper tube in a die in the dimension shown in the table at above.

6.2.5. Check

[Fig. 6-2-5] (P.4)

• Compare the flared work with a figure in right side hand.

• If flare is noted to be defective, cut off the flared section and do flaring work again.

A Unit body

B Lifting machine

C Nuts (field supply)

D Washers (accessory)

E M10 hanging bolt (field supply)

a Indoor unit

b Outdoor unit

Model Pipe

Outside

diameter

Min wall

thickness

Insulation

thickness

Insulation

material

mm inch mm inch mm inch

PEAD-

A09AA8

For liquid 6.35 1/4 0.8 1/32 8 5/16

Heat resisting

foam plastic

0.045 specific

gravity

For gas 9.52 3/8 0.8 1/32 8 5/16

PEAD-

A12AA8

For liquid 6.35 1/4 0.8 1/32 8 5/16

For gas 12.7 1/2 0.8 1/32 8 5/16

PEAD-

A15AA8

For liquid 6.35 1/4 0.8 1/32 8 5/16

For gas 12.7 1/2 0.8 1/32 8 5/16

PEAD-

A18AA8

For liquid 6.35 1/4 0.8 1/32 8 5/16

For gas 12.7 1/2 0.8 1/32 8 5/16

PEAD-

A24AA8

For liquid 9.52 3/8 0.8 1/32 8 5/16

For gas

15.88

5/8 1.0 1/32 8 5/16

PEAD-

A30AA8

For liquid 9.52 3/8 0.8 1/32 8 5/16

For gas

15.88

5/8 1.0 1/32 8 5/16

PEAD-

A36AA8

For liquid 9.52 3/8 0.8 1/32 8 5/16

For gas

15.88

5/8 1.0 1/32 8 5/16

a Copper tubes

b Good

c No good

d Tilted

e Uneven

f Burred

a Burr

b Copper tube/pipe

c Spare reamer

d Pipe cutter

a Flare nut

b Copper tube

a Flaring tool

b Die

c Copper tube

d Flare nut

e Yoke

Pipe diameter

(mm [in])

Dimension

A (mm [in])

B (mm [in])

When the tool for R410A is used

Clutch type

6.35 [1/4] 0 to 0.5 [0 to 1/32] 9.1 [3/8]

9.52 [3/8] 0 to 0.5 [0 to 1/32] 13.2 [17/32]

12.7 [1/2] 0 to 0.5 [0 to 1/32] 16.6 [21/32]

15.88 [5/8] 0 to 0.5 [0 to 1/32] 19.7 [25/32]

a Smooth all around b Inside is shining without any scratches

c Even length all around d Too much

e Tilted f Scratch on flared plane

g Cracked h Uneven

i Bad examples

+0

-0.4 [-1/32]

KJ79P806H01.book 13 ページ 2021年12月13日 月曜日 午後2時15分

Loading ...

Loading ...

Loading ...