Loading ...

Loading ...

Loading ...

22

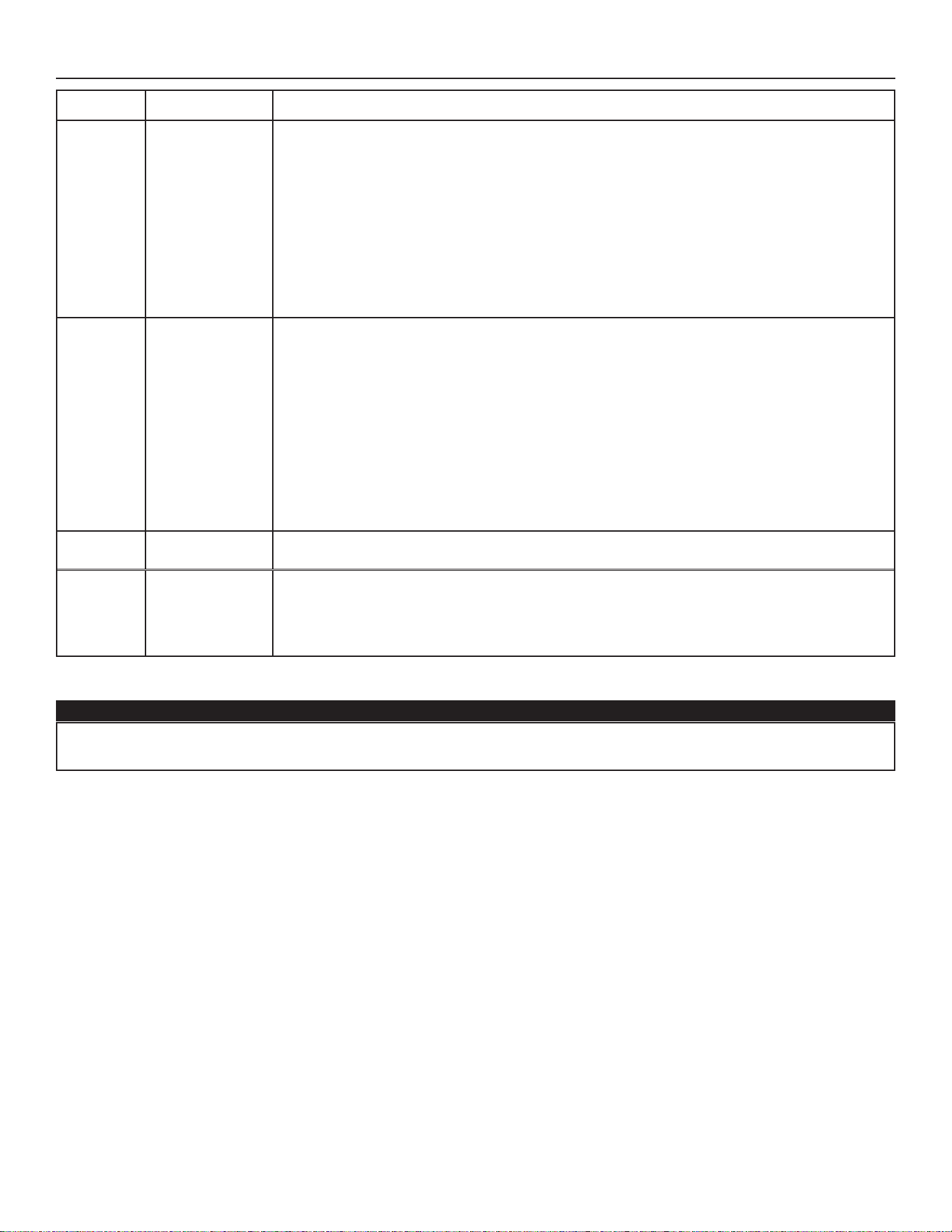

Warning deSCription Solution

W22

Supply airow

STEP 1: Unplug the unit. Perform a visual inspection of the supply damper system. Clean

lters, distribution registers and outside supply hood. Inspect ducting to ensure it is not

squeezed or bent. Plug the unit.

If STEP 1 did not x the problem, perform STEP 2: Remove ducting of the supply path. On the

LCD screen, select MAX to check if the unit is able to reach the selected ow. If so, review the

ducting path.

If STEP 2 did not x the problem, perform STEP 3: On the LCD screen, select the MIN and

MAX ow setting values then reset the unit. MAX ow value will display on the LCD screen. If

MAX ow is above desired MAX ow, set MAX and MIN ows.

If STEP 3 did not x the problem, perform STEP 4: Replace the supply blower and repeat

STEP 3.

If STEP 4 did not x the problem, perform STEP 5: Replace the electronic assembly.

W32

Exhaust airow

STEP 1: Unplug the unit. Perform a visual inspection of the exhaust damper system. Clean

lters, distribution registers and outside exhaust hood. Make sure no non-return damper

is installed in exhaust hood since it can freeze in winter. Inspect ducting to ensure it is not

squeezed or bent. Plug the unit.

If STEP 1 did not x the problem, perform STEP 2: Remove ducting of the supply path. On the

LCD screen, select MAX to check if the unit is able to reach the selected ow. If so, review the

ducting path.

If STEP 2 did not x the problem, perform STEP 3: On the LCD screen, select the MIN and

MAX ow setting values then reset the unit. MAX ow value will display on the LCD screen. If

MAX ow is above desired MAX ow, set MAX and MIN ows.

If STEP 3 did not x the problem, perform STEP 4: Replace the exhaust blower and repeat

STEP 3.

If STEP 4 did not x the problem, perform STEP 5: Replace the electronic assembly.

W52

Initial setting

incomplete

STEP 1: Press + or - to access the selection menu.

STEP 2: Complete conguration. (Refer to section 5 for more details).

W61

Protection mode

electronics

overheating

The unit is currently in protection mode. The power transmitted to the motor is deliberately

reduced to decrease electronics temperature. The unit will exit this mode by itself once

conditions are back to normal. It is normal to observe reduction in airows during this period.

This condition should appear only when the unit is set in high speed and located in a warmer

environment, for example over 30°C (86°F).

8. INSTALLER’S TROUBLESHOOTING (Cont’d)

Make sure that no piece of mineral wool will enter in the unit during installation. Otherwise, this could reduce

airow and generate vibrations and noise in the unit.

CAUTION

NOTE: 210 and 230 CFM models have a cooling fan in electrical box that can start if ambient temperature near the unit is

over 40°C (104°F).

180 CFM ERV Models

The unit will reduce airow by 30 CFM if the max airow during auto-balancing procedure is 130 CFM or less to prevent

ERV core membrane deformation due to very high static pressure (over 1.3 in. w.g.).

All 180 CFM Models

Error E22 or E32 will display if the maximum airow is 90 CFM or less during the auto-balancing procedure (the unit

will attempt to execute auto-balancing procedure 3 times before displaying an error). Static pressure of ducting shall be

reduced to allow good operation of the unit.

210 CFM ERV Models

The unit will reduce airow by 30 CFM if the max airow during auto-balancing procedure is 160 CFM or less to prevent

ERV core membrane deformation due to very high static pressure (over 1.3 in. w.g.).

All 210 and 230 CFM Models

Error E22 or E32 will display if the maximum airow is 120 CFM or less during the auto-balancing procedure (the unit

will attempt to execute auto-balancing procedure 3 times before displaying an error). Static pressure of ducting shall be

reduced to allow good operation of the unit.

8.1 elecTronic proTecTion To prevenT AbnormAl HiGH sTATic pressure

Loading ...

Loading ...

Loading ...