Loading ...

Loading ...

Loading ...

7

Important: All wires should be joined together using wire nuts,

solder, and/or vinyl tape. In wet environments like a valve box it is

recommended to use Orbit Grease Caps to prevent corrosion of the

connection and for protection from water infiltration.

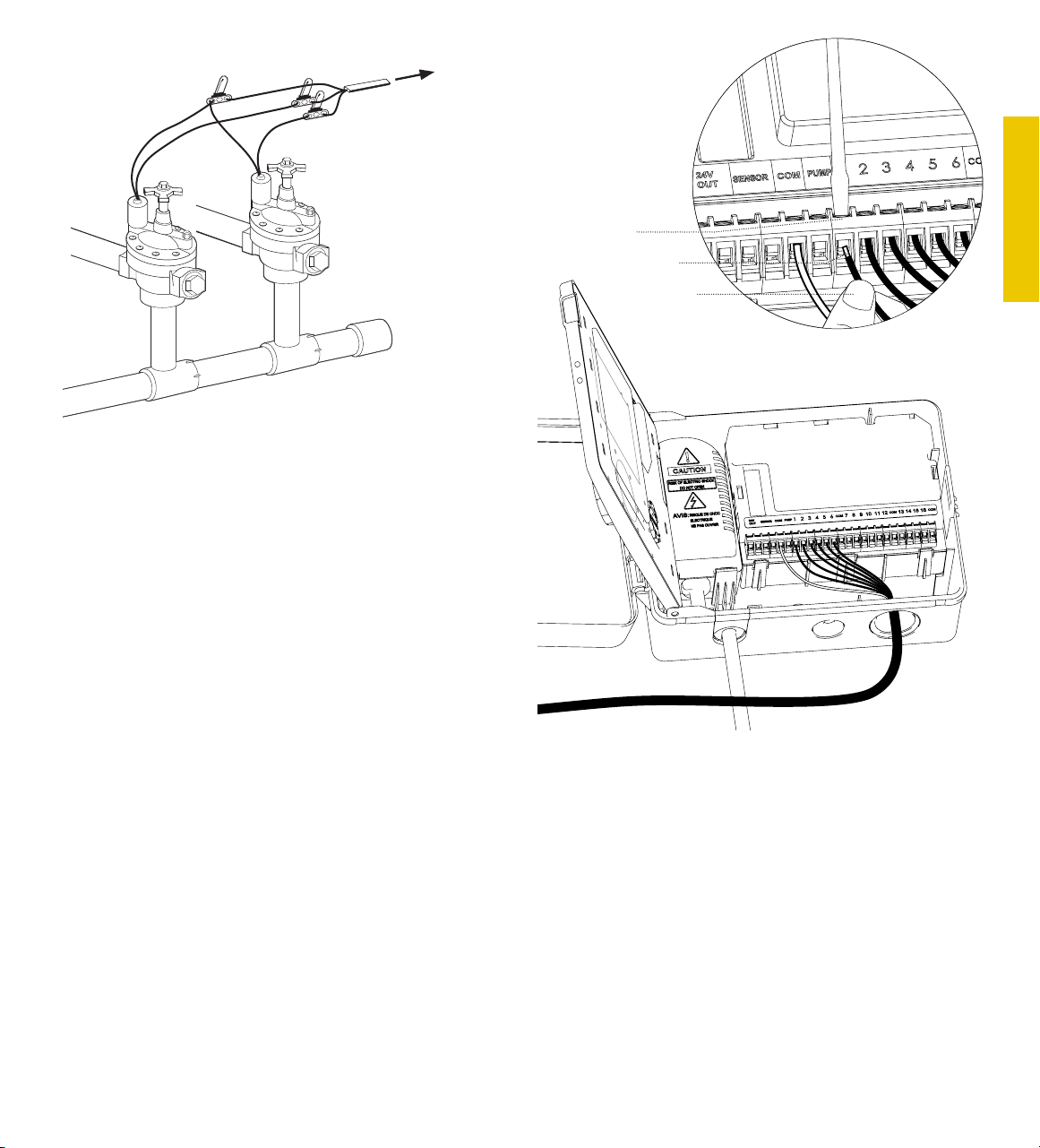

Wiring Electric Valves

Strip 1/2” (12 mm) of plastic insulation off the end of each individual

wire. Each valve has two wires. One wire (it doesn’t matter which

one) is to be connected as the common. The other valve wire is

to be connected to the specific station wire that will control that

valve. The common wires for all the valves can be connected

together to one common wire going to the controller. To avoid

electrical hazards, only one valve should be connected to each

station.

Important: The wire can be buried in the ground; however, for

more protection wires can be pulled through PVC pipe and buried

underground. Be careful to avoid burying the wires in locations

where they could be damaged by digging or trenching in the future.

Your timer is equipped with angled terminals for easy wire insertion.

Push common wire into the common terminal and, using the

included screwdriver, tighten the screw in the wire terminal to

secure the wire. Insert and tighten remaining wires to corresponding

terminal locations.

Station 1

Strip wire

Push in

Only connect one valve to

each terminal (station).

To

Timer

Wire Nut

Solenoid

Common

Wire

Valve

4. Connect Electrical Power

Indoor Locations – Insert the power cord into an 110V electrical

outlet.

Outdoor Locations – Insert the power cord into a 110 volt Ground

Fault Interrupter (GFI) outlet.

ENGLISH

Loading ...

Loading ...

Loading ...