Loading ...

Loading ...

Loading ...

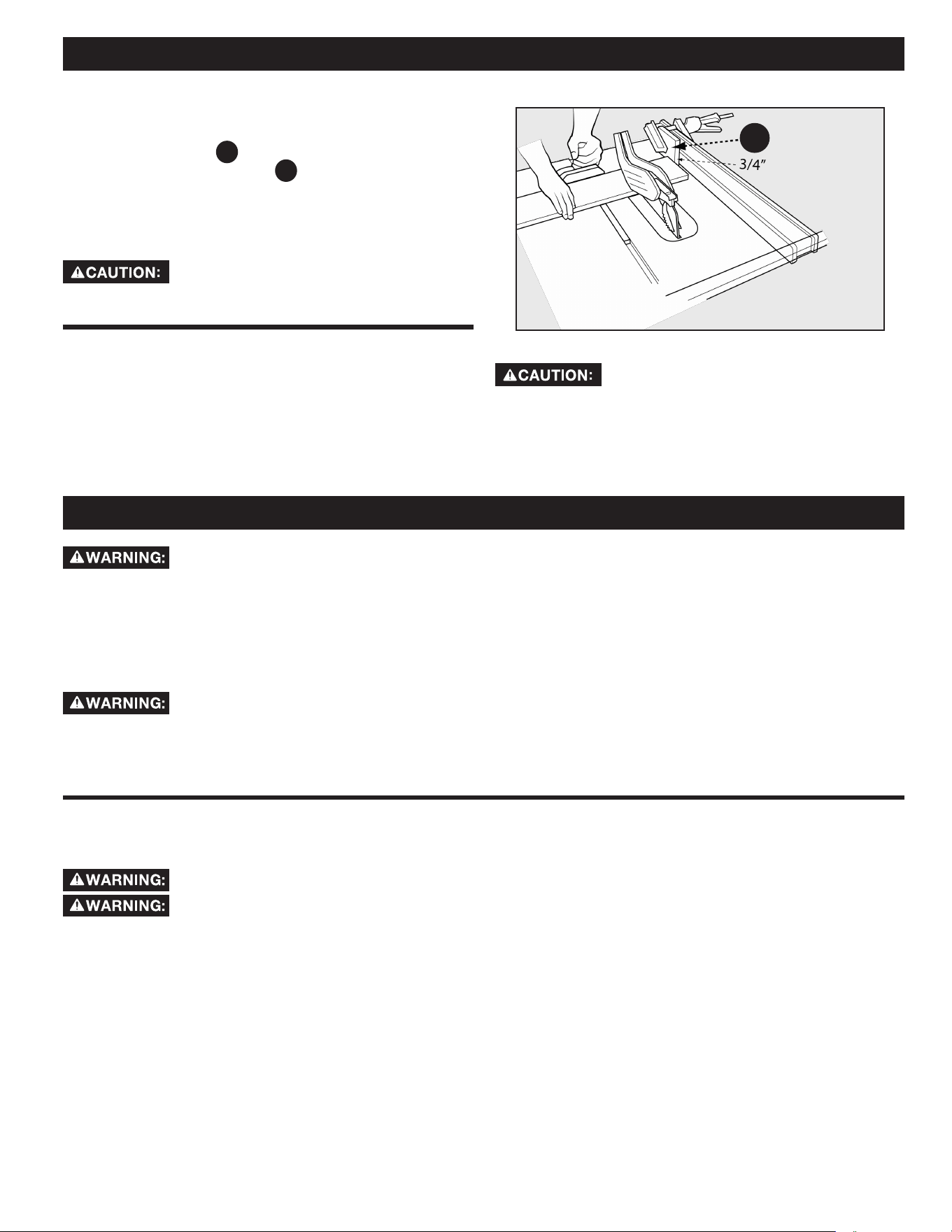

Figure 70

MAINTENANCE

CUT OFF GAUGE

When crosscutting a number of pieces to the same length, you can

clamp a block of wood

A

to the fence and use it as a cut-o

gauge. See Figure 70. The block

A

MUST be at least 3/4 inch

(19mm) thick to prevent the cut o piece from binding between the

blade and the fence. Once the cut-o length is determined, lock the

fence and use the miter gauge to feed the workpiece into the blade.

ALWAYS position the cut-o gauge in front

of the saw blade.

JIGS

Jigs may be created with a variety of special set-ups to control

particular workpiece shapes for particular cuts. Guidance on how to

make specialized jigs can be found in woodworking and carpentry

websites and publications.

DO NOT attempt to create or use a jig unless

you are thoroughly familiar with table saw safety. DO NOT use any

jig that could result in pinching a kerf or jamming the workpiece

between the jig and the blade. Incorrect setups may cause kickback

which could result in serious injury.

Wear certified safety equipment for eye, hearing and respiratory protection while using compressed air.

Always turn saw o and unplug from power source before making adjustments or performing maintenance.

Specific areas which require regular maintenance include:

RIVING KNIFE CLAMP PLATE: Keep this area free of dust and debris buildup. Blow out area regularly with compressed air.

NOTE: If the riving knife clamp can’t move freely, have the saw serviced by authorized DELTA

®

service center personnel.

BEVEL GEARS: KEEP the bevel gears free of dust and debris buildup. Blow out area regularly with compressed air. Use a lithium-

based multipurpose grease as needed on these gears.

CLEAN SAWDUST BUILDUP OUT OF CABINET PERIODICALLY: NOTE: Debris can also be removed from the saw from below the

throat plate, inside the dust port.

A

CUTTING AIDS AND ACCESSORIES

To reduce the risk of injury, turn unit o and disconnect it from power source before cleaning orservicing, before

installing and removing accessories, before adjusting and when making repairs. An accidental start-up can cause injury.

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp cloth. NEVER use

solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

Wear certied safety equipment for eye, hearing and respiratory protection while using compressed air.

MAINTENANCE REMINDERS

For best performance use a shop vacuum or blower to KEEP saw blade area, the dust collection system, the guarding system and rails

free of saw dust and other debris.

39

Loading ...

Loading ...

Loading ...