Loading ...

Loading ...

Loading ...

9WWW.SENIXTOOLS.COM

SAW CHAIN LUBRICATION

FILLING THE OIL TANK

The saw chain must be tensioned properly in order to

ensure safe operation.

Make sure that no dirt gets into the oil tank to prevent

clogging in the oil nozzle.

Because the saw chain heats up during operation, its

length can uctuate. Check the chain tension every

10 minutes of operation and adjust as necessary,

particularly for new saw chains.

The pole saw features automatic chain lubrication.

Never operate the pole saw without saw chain oil. The

use of the pole saw without enough saw chain oil will

damage the unit.

1. Place the saw on a level surface. Clean the area

around the oil tank cap and then open it.

IMPORTANT: Only use SAE300 saw chain oil. Other

oils will run the risk of damaging the unit and voiding the

warranty. Take note of temperature conditions. Using

the saw at various temperatures requires the use of

differing oils. To ensure a sufcient layer of lubricant at

lower temperatures, use liquid oil (low viscosity).

TIP: The saw chain shortens when cooling down.

Loosen the saw chain after work is completed to

elongate the chain’s life and prevent possible damage.

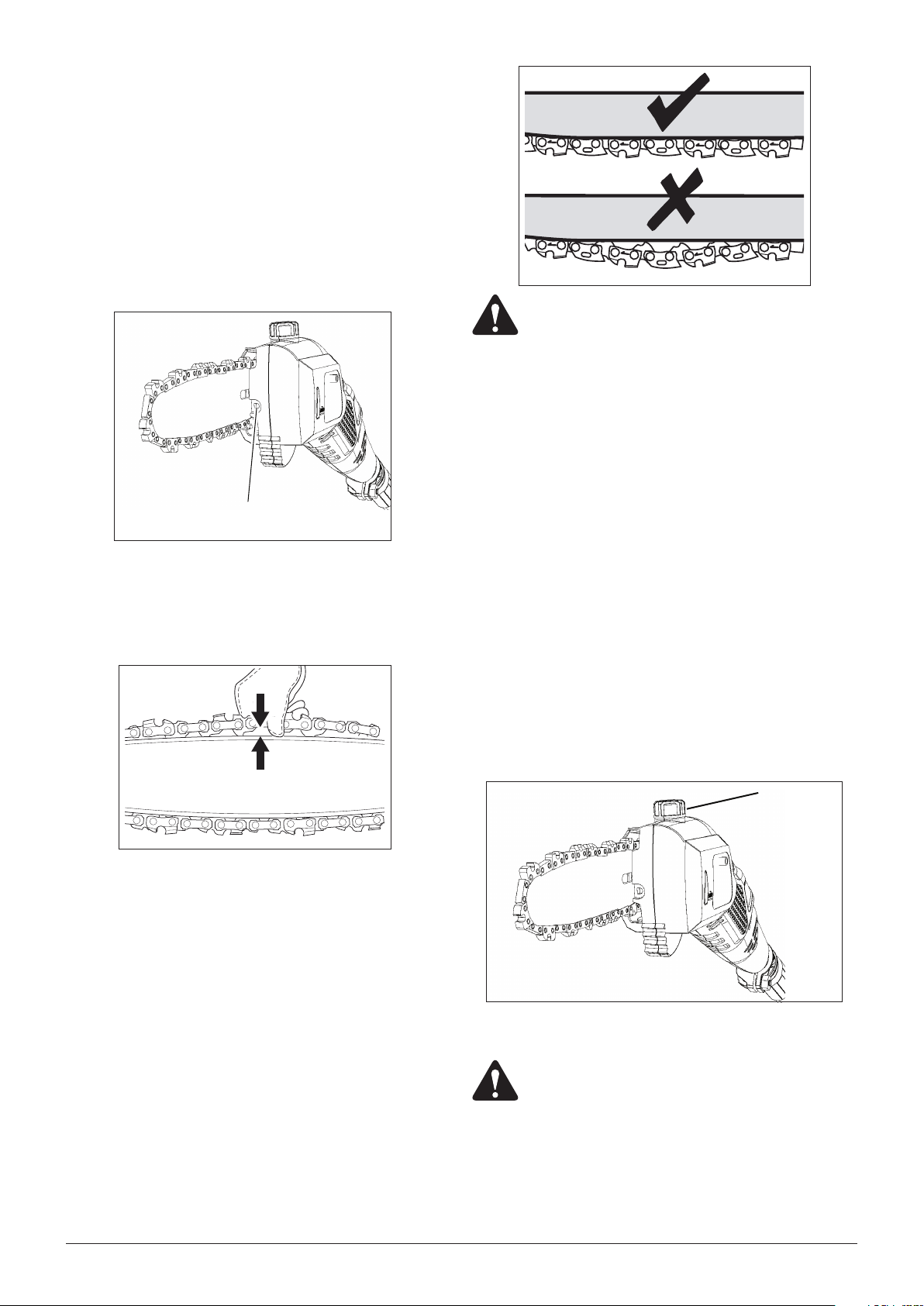

3. Wearing protective gloves, wrap the saw chain

around the chain bar, making sure that the teeth are

aimed in the direction of rotation. The chain should

be properly set in the slot running along the entire

outside edge of the chain bar.

4. Place the saw chain around the sprocket while lining

up the slot in the chain bar with the internal bolt at the

base of the saw and the chain tensioning pin in the

chain bar’s pin hole. The chain tensioning pin may

need adjustment to properly align with the hole in the

chain bar. Use a at-blade screwdriver to turn the

chain tensioning screw to adjust the location of the

pin until it ts in the chain bar.

5.Turn the chain tensioning screw clockwise to

preliminarily tighten the chain bar enough that it stays

in place.

6. Install the step washer and locking nut. Using the

supplied wrench, turn the locking nut clockwise to

tighten it. DO NOT overtighten.

2. Fill the oil tank with 2.04 oz. (60 ml) of saw chain and

bar oil.

3. Close the oil tank cap.

7. Check the chain tension by pulling the saw chain

away from the chain bar. A properly tensioned chain

should have roughly 0.08 inch (2 mm) of distance

between itself and the bar guide.

8. If adjustments are needed, loosen the bar adjustment

locking nut one full turn.

9. To adjust the saw chain tension, turn the chain

tensioning screw. Turning the screw clockwise

increases the tension while turning it counter-

clockwise decreases tension. A properly tensioned

chain should have no sag and should only be able to

be pulled 0.08 inch (2 mm) away from the chain bar

of the saw.

10. Once the chain is properly tensioned, tighten the bar

adjustment locking nut. DO NOT over-tension the

chain: this will lead to excessive wear and reduces

the life of both the bar and chain.

CAUTION:

CAUTION:

Chain

Tensioning

Screw

Chain Tensioning

Screw

0.08” (2 mm)

Oil tank cap

Loading ...

Loading ...

Loading ...