Loading ...

Loading ...

Loading ...

Specifications subject to change without notice.

8 421 01 5501 05

Check Charge

Factory charge amount and desired subcooling are shown

on unit rating plate. Charging method is shown on

information plate inside unit. To properly check or adjust

charge, conditions must be favorable for subcooling

charging. Favorable conditions exist when the outdoor

temperature is between 70_F and 100_F (21.11_C and

37.78_C), and the indoor temperature is between 70 _F and

80_F (21.11_C and 26.67_C).

Follow the procedure below:

Adjust charge by adding or removing 0.6 oz/ft of 3/8 liquid

line above or below 15ft (4.57 m) respectively.

For standard refrigerant line lengths (80 ft/24.38 m or less),

allow system to operate in cooling mode at least 15 minutes.

If conditions are favorable, check system charge by

subcooling method. If any adjustment is necessary, adjust

charge slowly and allow system to operate for 15 minutes to

stabilize before declaring a properly charged system.

If the indoor temperature is above 80_F (26.67_C), and the

outdoor temperature is in the favorable range, adjust system

charge by weight based on line length and allow the indoor

temperaturetodropto80_F (26.67_C) before attempting to

check system charge by subcooling method as described

above.

If the indoor temperature is below 70_F (21.11_C), or the

outdoor temperature is not in the favorable range, adjust

charge for line set length above or below 15ft (4.57 m) only.

Charge level should then be appropriate for the system to

achieve rated capacity. The charge level could then be

checked at another time when the both indoor and outdoor

temperatures are in a more favorable range.

NOTE: If line length is beyond 80 ft (24.38 m) or greater

than 35 ft (10.7 m) vertical separation, see Long Line

Application Guideline for special charging requirements.

Final Checks

IMPORTANT: Before leaving job, be sure to do the following:

1. Ensure that all wiring is routed away from tubing and

sheet metal edges to prevent rub - through or wire

pinching.

2. Ensure that all wiring and tubing is secure in unit

before adding panels and covers. Securely fasten all

panels and covers.

3. Tighten service valve stem caps to 1/12 - turn past

finger tight.

4. Leave Owner’s Manual with owner. Explain system

operation and periodic maintenance requirements

outlined in manual.

CARE AND MAINTENANCE

For continuing high performance and to minimize possible

equipment failure, periodic maintenance must be performed

on this equipment.

Frequency of maintenance may vary depending upon

geographic areas, such as coastal applications. See

Owner’s Manual for information.

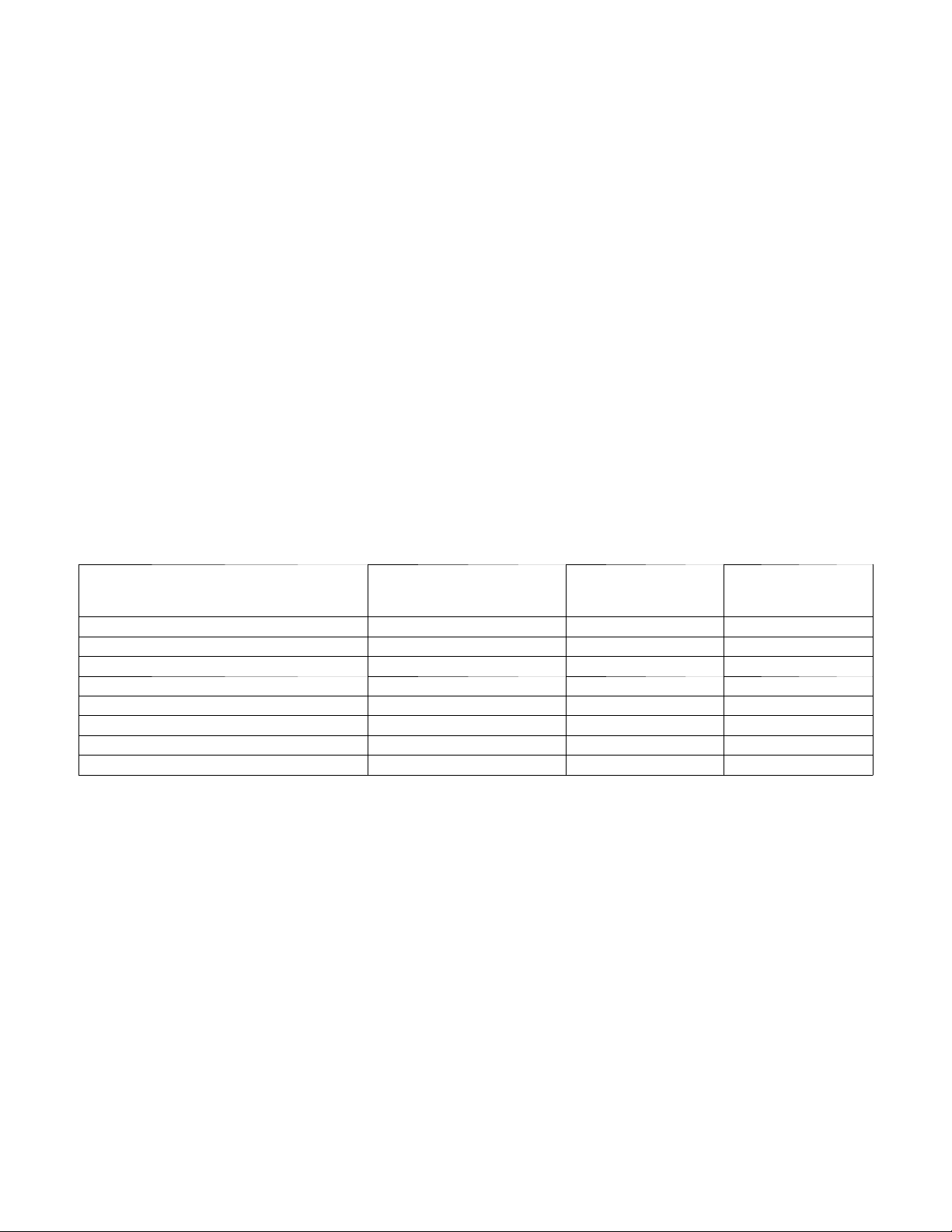

Table6–Accessory Usage

ACCESSORY

REQUIRED FOR LOW- AMBIENT

COOLING APPLICATIONS

(Below 55F/12.8_C)

REQUIRED FOR LONG LINE

APPLICATIONS*

REQUIRED FOR

SEA COAST

APPLICATIONS

(Within 2 miles/3.22 km)

Compressor Start Assist Capacitor and Re lay Ye s Ye s No

Crankcase Heater Ye s Ye s No

Evaporator Freeze Thermostat Ye s No No

Hard Shut- Off TXV Ye s Ye s ‡ No

Liquid Line Solenoid Valve No No No

Low - ambient Pressure Switch Ye s No No

Support Feet Recommended No Recommended

Winter Start Control Ye s * * No No

* For tubing line sets between 80 and 200 ft. (24.38 and 60.96 m) and/or 35 ft. (10.7 m) vertical differential, refer to Long Line Application Guideline.

‡ TXV required beyond 35 ft. (10.7 m) vertical separation or 50 ft. (15.2 m) total length.

** Can only be installed in conjunction with the Low Pressure Switch.

Loading ...

Loading ...