Loading ...

Loading ...

Loading ...

Specifications subject to change without notice.

4 421 01 5501 05

Evacuate Refrigerant Tubing and Indoor

Coil

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Never use the system compressor as a vacuum

pump.

Refrigerant tubes and indoor coil should be evacuated using

the recommended deep vacuum method of 500 microns.

The alternate triple evacuation method may be used (see

triple evacuation procedure in service manual). Always

break a vacuum with dry nitrogen.

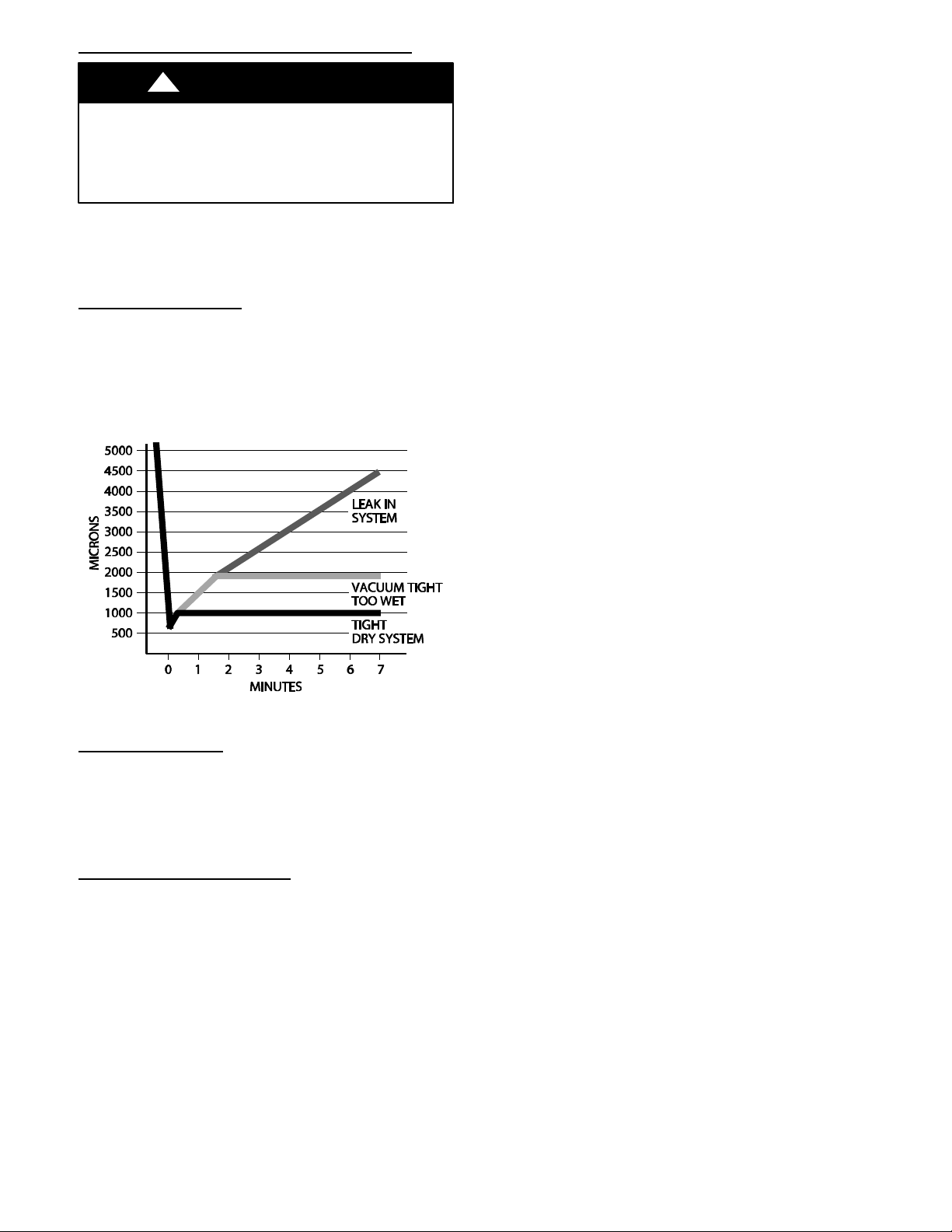

Deep Vacuum Method

The deep vacuum method requires a vacuum pump capable

of pulling a vacuum of 500 microns and a vacuum gage

capable of accurately measuring this vacuum depth. The

deep vacuum method is the most positive way of assuring a

system is free of air and liquid water. A tight dry system will

hold a vacuum of 1000 microns after approximately 7

minutes. See Fig. 4.

A95424

Fig. 4 - Deep Vacuum Graph

Final Tubing Check

IMPORTANT: Check to be certain factory tubing on both

indoor and outdoor unit has not shifted during shipment.

Ensure tubes are not rubbing against each other or any

sheet metal or wires. Pay close attention to feeder tubes,

making sure wire ties on feeder tubes are secure and tight.

Installing with Indoor Piston

Air Conditioner Matched with Factory Approved Piston

Indoor

Air conditioners may be installed with piston fan coils as a

system when the air conditioner and fan coil are listed as a

system in the AHRI directory. All rated piston fan coils are

shipped with the appropriate size piston for the equal

tonnage air conditioner. Matching air conditioners with piston

indoors of larger tonnage size requires a TXV.

Air Conditioner Applied as Replacement Component

If the air conditioner is installed as a replacement component

in an existing piston indoor system, the piston size in the

indoor unit should be changed to the size required for the air

conditioner which can be found in the Specification Sheet.

Units with Cooling Mode TXV

Units installed with cooling mode TXV require charging by

the subcooling method.

1. Operate unit a minimum of 15 minutes before

checking charge.

2. Measure liquid service valve pressure by attaching an

accurate gage to service port.

3. Measure liquid line temperature by attaching an

accurate thermistor type or electronic thermometer to

liquid line near outdoor coil.

4. Refer to unit rating plate for required subcooling

temperature.

5. Refer to Table 2 - Rating Plate (required) Subcooling

Temperature. Find the point where required

subcooling temperature intersects measured liquid

service valve pressure.

6. To obtain required subcooling temperature at a

specific liquid line pressure, add refrigerant if liquid line

temperature is higher than indicated or reclaim

refrigerant if temperature is lower. Allow a tolerance of

3_F(1.7_C).

Units with Indoor Piston

Units installed with indoor pistons require charging by the

superheat method.

The following procedure is valid when indoor airflow is within

21 percent of its rated CFM.

1. Operate unit a minimum of 15 minutes before

checking charge.

2. Measure suction pressure by attaching an accurate

gage to suction valve service port.

3. Measure suction temperature by attaching an accurate

thermistor type or electronic thermometer to suction

line at service valve.

4. Measure outdoor air dry bulb temperature with

thermometer.

5. Measure indoor air (entering indoor coil) wet- bulb

temperature with a sling psychrometer.

6. Refer to Table 3 - Superheat Charging - AC Only.

Find outdoor temperature and evaporator entering air

wet- bulb temperature. At this intersection, note

superheat. Where a dash (- - ) appears on the table,

do not attempt to charge system under these

conditions or refrigerant slugging may occur. Charge

must be weighted in, adding or removing 0.6 oz/ft of

3/8 liquid line above or below 15 feet (4.6m)

respectively.

7. Refer to Table 4 - Required Suction- Line

Temperature. Find superheat temperature (from #6

above) and suction pressure. At this intersection, note

suction line temperature.

8. If unit has a higher suction line temperature than

charted temperature, add refrigerant until charted

temperature is reached.

9. If unit has a lower suction line temperature than

charted temperature, reclaim refrigerant until charted

temperature is reached.

10. When adding refrigerant, c harge in liquid form into

suction service port using a flow- restricting device.

11. If outdoor air temperature or pressure at suction valve

changes, charge to new suction line temperature

indicated on chart.

12. Optimum performance will be achieved when the

operating charge produces 10_F suction superheat at

suction service valve with 95_F(35_C) outdoor

ambient and 80_F(27_C) dry bulb (67_F/19

_C) wet

bulb) indoor temperature (DOE “A” test conditions) at

rated airflow.

Loading ...

Loading ...

Loading ...