Loading ...

Loading ...

Loading ...

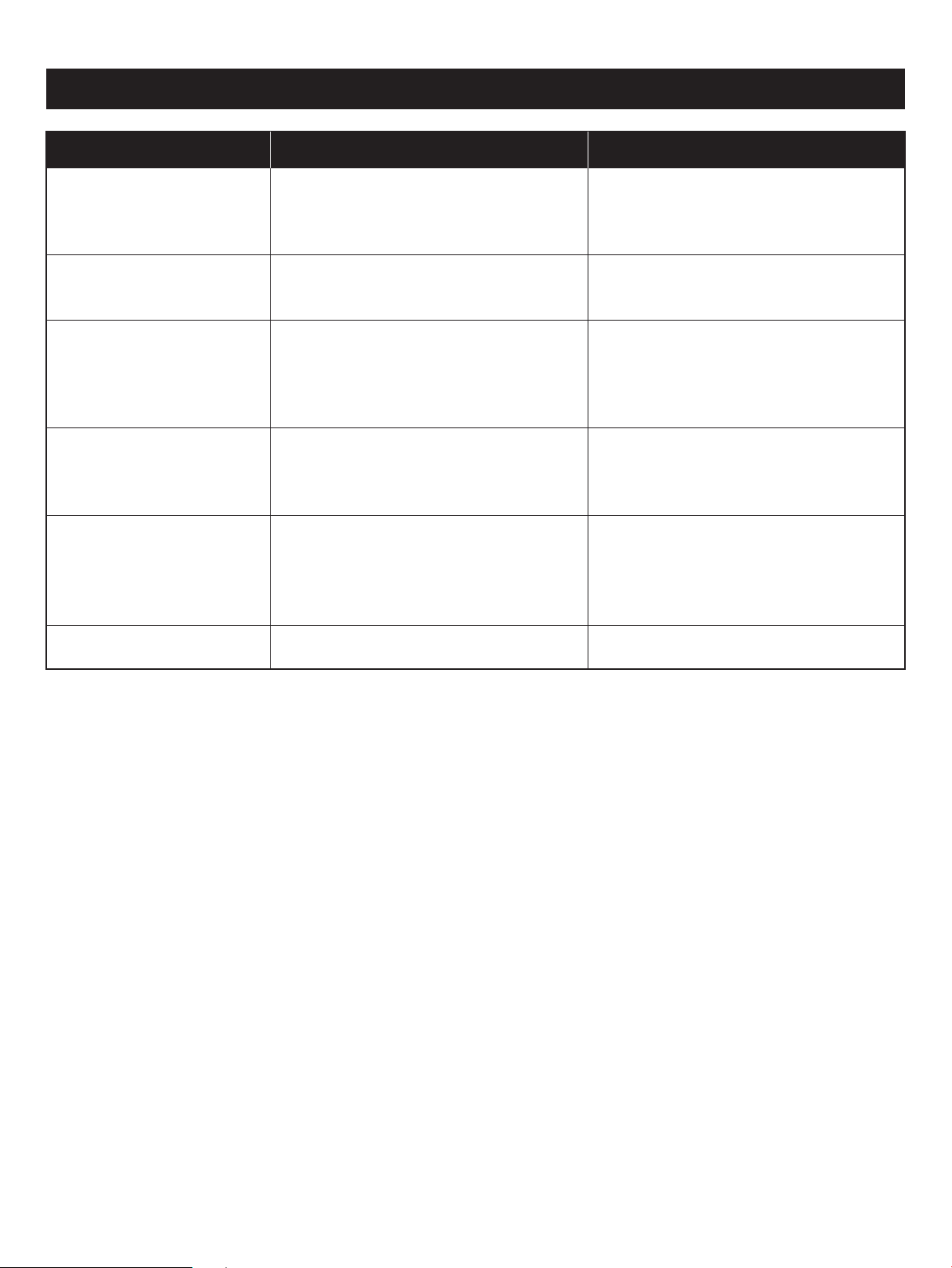

TROUBLESHOOTING

Noisy operation • Adjust tension

• Remove spindle/quill assembly lubricate

• Tighten pulley

• Replace bearing

• Incorrect belt tension

• Dry spindle

• Loose pulley

• Bad bearing

Excessive drill wobble • Tighten by pressing chuck down on table

• Replace spindle shaft or bearing

• Replace chuck

• Loose chuck

• Worn spindle shaft or bearing

• Bad chuck

PROBLEM PROBLEM CAUSE CORRECTIVE ACTION

Motor will not start • Check power cord

• Check motor connection

• Check switch connections

• Replace motor

• Replace switch

• Power supply

• Motor connection

• Switch connections

• Motor winding burned

• Bad switch

Drill binds in workpiece • Apply less pressure

• Check belt tension

• Tighten drill with key

• Change speed

• Excessive pressure on feed handle

• Loose belt

• Loose drill

• Speed too fast

Drill burns or smokes • Refer to speed chart

• Clean drill

• Check sharpness and taper

• Use lubrication while drilling

• Apply less pressure

• Incorrect speed, slow down RPM

• Chips are not discharging

• Dull drill or not cut properly for material

• Needs lubrication

• Feed pressure wrong

Table difcult to raise • Lubricate with light oil

• Loosen clamp

• Needs lubrication

• Table lock tightened

Page 27

Loading ...

Loading ...