Loading ...

Loading ...

Loading ...

30

Charge the correct refrigerant quantity.

If not, compressor may be damaged

due to an excessive or insufficient

refrigera

nt charge.

Refrigerant charging from check joint of

gas stop valve may lead to compressor

failure. Be sure to charge refrigerant

from the check joint of liquid stop valve.

Insulate the liquid piping and gas piping

completely to avoid decreasing of

performance and dewing on the surface

of the pipe.

Insulate the flare nut and union of the

piping connection with insulation.

Check to ensure that there is no gas

leakage. If a severe refrigerant leakage

occurs, it will cause difficulty with

breathing or harmful gases would

generate when contacting with fire in the

room

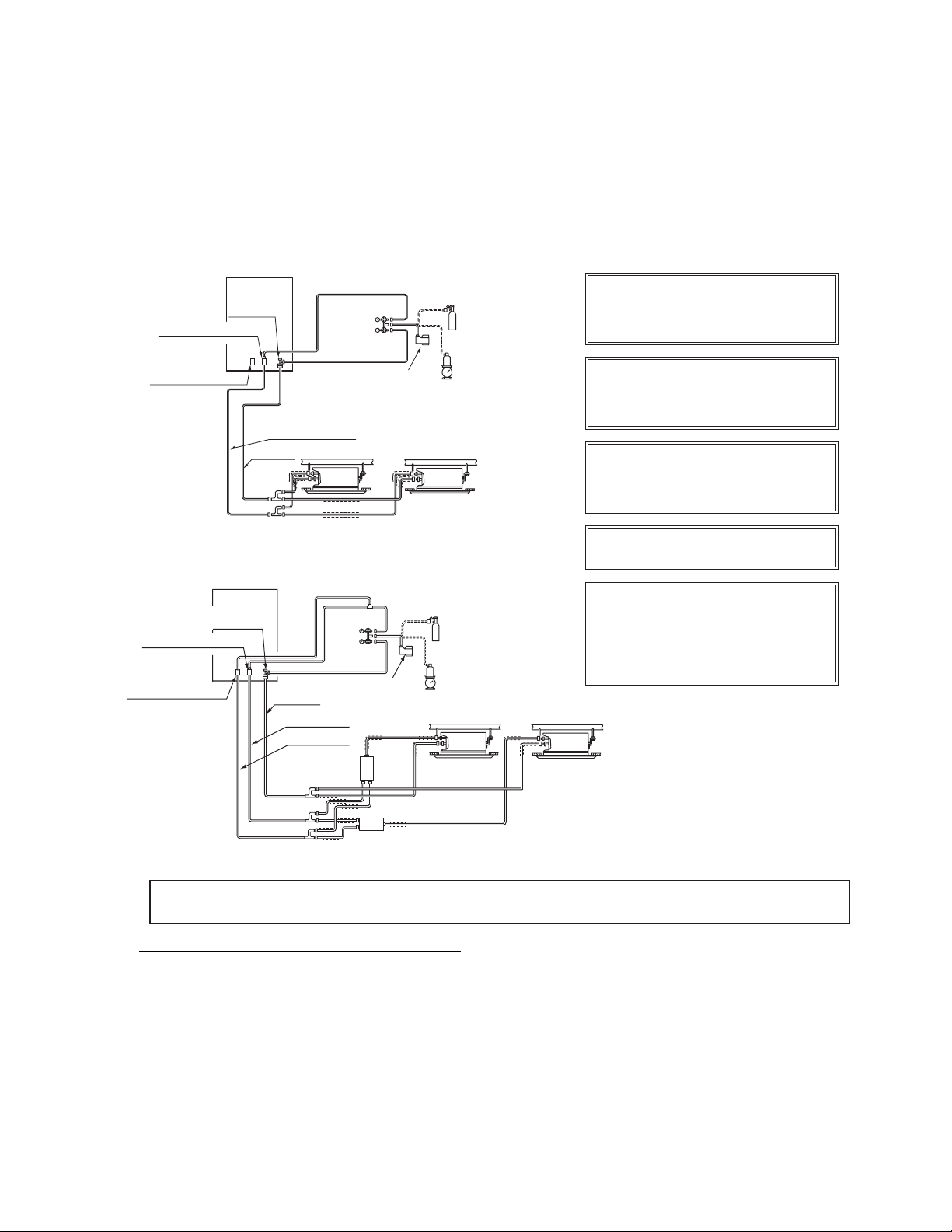

Stop Valve

(Liquid Piping)

Stop Valve

(High/Low Pressure Gas Piping)

Stop Valve

(Low Pressure Gas Piping)

High/Low Pressure Gas Piping

Liquid Piping

Insulation

Switch BOX

[Cover the gas and liquid piping with insulation.]

Switch BOX

Outdoor Unit

Vacuum Pump

Siphonic Refrigerant Cylinder

(R410A)

Weigher

Nitrogen Tank

(for Nitrogen Purging during

Brazing and Air Tight Test)

Indoor Unit

Manifold Pipe

Manifold

Gauge

Insulation

Outdoor Unit

Stop Valve

Manifold

Gauge

Vacuum Pump

Nitrogen Tank

(for Nitrogen Purging during

Brazing and Air Tight Test)

Siphonic Refrigerant Cylinder

(R410A)

Weigher

High/Low

Pressure Gas Piping

Liquid Piping

(Liquid Piping

Stop Valve

(High/Low Pressure Gas Piping)

Stop Valve

(Low Pressure Gas Piping)

Manifold Pipe

Insulation

< Heat Recovery System >

Indoor Unit

(or Water Module)

[Cover the gas and liquid piping with insulation.]

(or Water Module)

Low Pressure

Gas Piping

7.3 Charging Operation

After vacuum pumping, check that the gas and liquid stop valves are completely closed.

Charge additional refrigerant (tolerance: 1.1lbs(0.5kg)) from the check joint of liquid stop valve. If the

specified refrigerant quantity can not be charged, follow the procedure below.

Fully open the stop valve for gas side

(In case of heat recovery system, fully open the stop valve for

high/low pressure and low

pressure gas pipe).

(2)

RTotally Charged Refrigerant Quantity in System (kg)

VRoom Volume for each Indoor Unit (ft

3

)

CCritical Concentration 0026lbs/ft

3

02

)

●

Special Attention Regarding Refrigerant Gas Leakage

Pay attention to the critical gas concentration to avoid accidental refrigerant gas leakage before installing

air conditioning systems.

≤

(1)

(2)

(2)

Operate the compressor in cooling mode and charge refrigerant (tolerance: 1.1lbs(0.5kg)) from the

check joint of the liquid stop valve. At this time,

the

liquid stop valve is slightly opened.

(3)

(3)

(3)

After refrigerant charge, fully open the stop valve for both liquid and gas sides.

* This value should be decided according to the each country’s regulationIS197SHR

S1Iis higher than , take the following actions:

1) Provide a gas leakage detector and fan controlled by its gas leakage detector.

2) Provide effective opening in the wall or door for ventilation to next door so that the critical gas concentrationcan

be maintained lower than the above value. (n opening 0.15% of floor surface at

the lowerpart of a door.)

Loading ...

Loading ...

Loading ...