VACUUM/FUEL PUMP TESTER MANUAL

W80594

PURPOSE OF THE VACUUM AND FUEL PUMP TESTER

This vacuum and fuel pump tester is designed for:

1. Quick accurate testing and setting of the carburetor.

2. Checking sticky valves.

3. Checking valve timing.

4. Detecting burnt valves or insufficient valve tappet clearance.

5.

Detecting weak valve springs, worn valve stem guides or leaking head gasket.

6. Testi

ng carburetor choke.

7. Fuel pump suction testing.

8. Fuel pump pressure testing.

WARNING: Not for use with Fuel Injection Systems. Damage to gauge will occur.

Note: Vacuum gauge readings are dependent on altitude and the gauge is calibrated

by the factory for sea level operation. For every 1,000 ft. above sea level, the vacuum

gauge will read low by one inch of vacuum or one division

on the dial.

Example: A reading of 20 inches vacuum at sea level would read only 19 inches at

1,000 ft. above sea level and 18 inches at 2,000 ft. above sea level.

CONNECTION FOR MANIFOLD VACUUM TEST: 1 thru 6

On some 4 and 6 cylinder engines, the intake manifold has a pipe plug that may be

removed and a adaptor may be used (See Fig. A). Make sure the connection is tight,

with no leaks, and there is suction.

On late model cars that are equipped with vacuum operated accessories, connect the

vacuum gauge in place of the accessory fitting on the intake manifold. (See Fig. B)

CAUTION: Before starting engine be sure gauge and hose are located away from

moving parts or hot manifold.

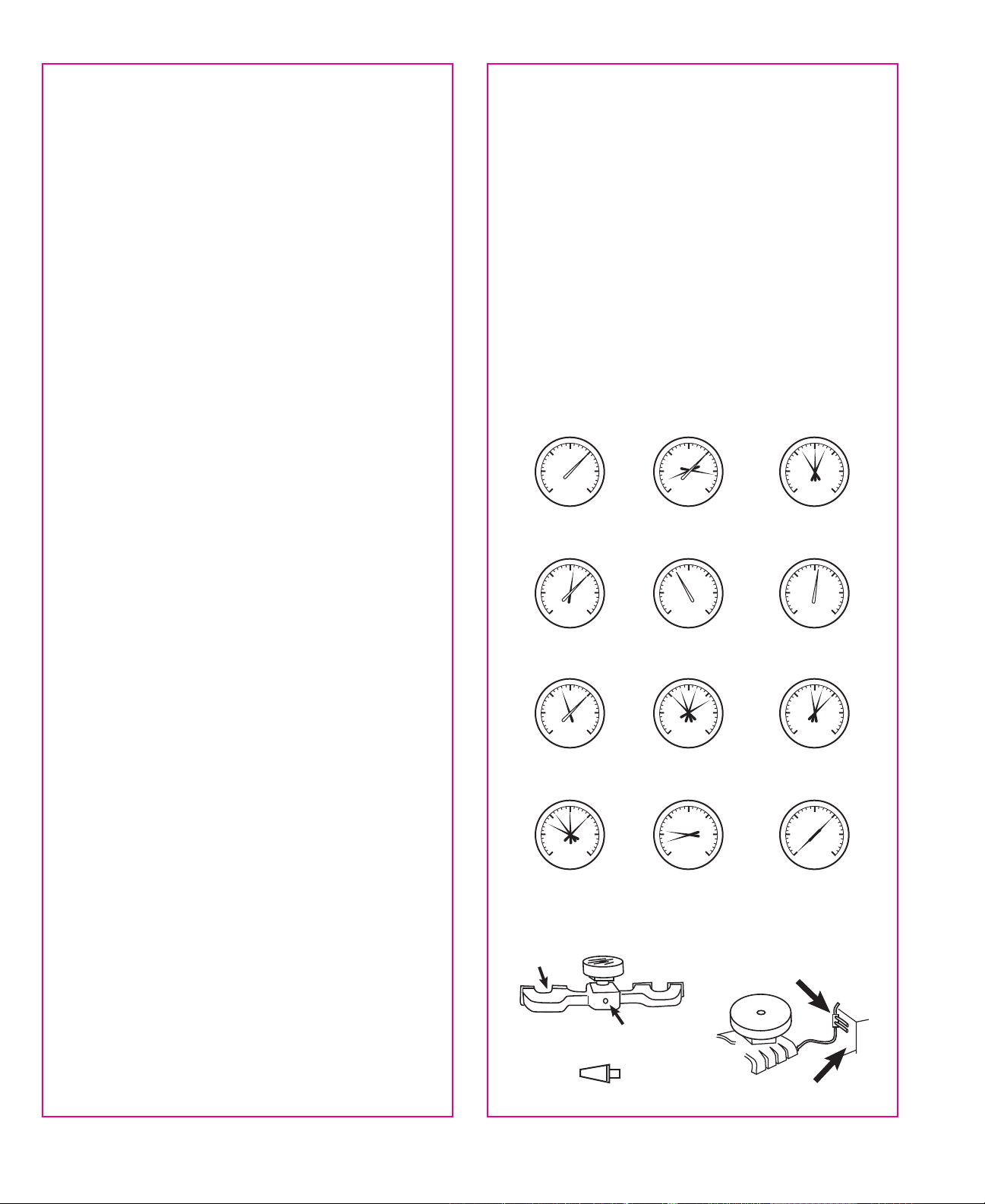

TEST 1: Testing and setting of the carburetor

Start the engine and allow sufficient time to reach normal operating temperature. With

the engine at normal idle speed(See your service manual specifications for idle speed)

the vacuum gauge should read in the range of 17-22 in. and should hold steady (See

chart, Fig. 1 and Fig. 2).

In making carburetor adjustments it is important that the engine speed be in the proper

range for slow and fast idle. While these speeds may be estimated by ear, the tests

are best performed using an Idle Tachometer which provides an accurate measure of

engine speed. If the vacuum is low and floating (See Chart, Fig. 3), adjust the idle

mixture screw either richer or leaner to give the highest vacuum reading without

appreciable vibration.

To make the high speed carburetor adjustment, set carburetor throttle on high idle

cam. Adjust the high speed mixture screw to give the highest vacuum reading without

appreciable vibration.

Note: Not all carburetors are equipped with a high speed mixture screw (See your

service manual).

TEST 2: Checking sticking valves

With engine running at idle speed; observe the vacuum gauge; if the pointer drops

intermittently about four divisions, the valves are sticking. (See Chart, Fig. 4). To

confirm this condition, inject penetrating oil into the intake manifold for temporary

relief. If the intermittent drop stops temporarily, the valves are sticking.

TEST 3: Valve timing

If valve timing is off any appreciable amount, the vacuum reading will be steady but

slow (See Chart, Fig. 5) and a high reading cannot be obtained. If the ignition timing is

off, the vacuum reading will also be steady but low (See Chart, Fig. 6).

TEST 4: Burnt valves or insufficient valve tappet clearance

If the valves are burnt, the vacuum reading will constantly drop whenever burnt valves

come into operation (See Chart, Fig. 7),

TEST 5: Weak valve springs, worn valve guides or

leaking head gasket

If the vacuum reading is normal and steady at idle speeds but the pointer vibrates

excessively at higher speeds, the valve springs are weak (See Chart, Fig. 8). If the

vacuum reading vibrates excessively at idling speeds, but the pointer steadies with the

increasing speed of the engine, the valve stem guides are worn (See Chart, Fig. 9). If

the pointer vibrates excessively at all speeds, look for a leaking head gasket (See

Chart, Fig. 10).

TEST 6: Choke test

Remove the high tension wire from the distributor and ground it. With the throttle

closed, crank the engine. A REMOTE STARTER SWITCH permits one person to

crank the engine from under the hood. If the pointer stays around 3-6 in. (See Chart,

Fig. 11), the choke valve is failing to close, the riser tube is burned or there are air

leaks in the manifold.

TEST 7: Fuel pump test

Disconnect the gasoline line from the tank to the fuel pump. Connect the vacuum

gauge to this point on the fuel pump. Start the engine (the gasoline in the carburetor

will generally run the engine for a few minutes before the engine will stop), the vacuum

gauge will build up to 10 in. vacuum if the fuel pump is in good condition.

FUEL PUMP PRESSURE TEST

Disconnect the gasoline line from the carburetor between the carburetor and the fuel

pump. Connect the vacuum gauge to the line connected to the fuel pump. Start the

engine and run it at idling speed. See manufacturers specifications for recommended

operating fuel pump pressure. The fuel pump pressure should hold for several minutes

after the engine is stopped before gradually dropping to zero. If the pressure drops

rapidly look for a worn pump valve, broken diaphragm or leaks around the diaphragm.

NOTE: The vacuum gauge is equipped with an impulse damper. This impulse damper

is located in the gauge fitting to which the hose is connected. This prevents excessive

pulsations of the pointer when making vacuum tests. This restriction or impulse

damper may become clogged after considerable use. It can be cleaned by pulling the

rubber hose from the gauge and using a stiff piece of wire of 0.043” dia. pushing it

through orifice.

NOTE: A bourbon tube vacuum gauge is a very delicate instrument and should be

handled and stored in the same manner as any expensive automotive test instrument.

In the event your gauge pointer shifts off “zero” the gauge can be corrected by:

1. Removing the chrome ring that holds the lens.

2. With needle nose pliers lift the pointer off the pivot. Use caution to avoid bending.

3. Reposition pointer to indicate “zero”. Press pointer down with fingers only. Caution:

Do not strike pointer with any object. Check pointer by trying to lift with fingers lightly.

4. Replace the lens and chrome ring by snapping into place.

Your gauge is now ready for use once again.

VACUUM DIAGNOSIS CHART

WHITE POINTER INDICATES STEADY HAND

BLACK POINTER INDICATES FLUCTUATING HAND

0

30

25

20

15

10

5

0

30

25

20

15

10

5

0

30

25

20

15

10

5

0

30

25

20

15

10

5

0

30

25

20

15

10

5

0

30

25

20

15

10

5

0

30

25

20

15

10

5

0

30

25

20

15

10

5

0

30

25

20

15

10

5

0

30

25

20

15

10

5

0

30

25

20

15

10

5

0

30

25

20

15

10

5

FIG. 1

FIG. 2

FIG. 3

FIG. 4

FIG. 5

FIG. 6

FIG. 7

FIG. 8

FIG. 9

FIG. 10

FIG. 11

FIG. 12

NORMAL MOTOR NORMAL MOTOR

(Opened & closed throttle,

rings & valves OK)

FAULTY CARBURETOR

ADJUSTMENT

STICKING VALVES LATE VALVE TIMING

LATE IGNITION TIMING

BURNT OR LEAKING

VALVES

WEAK VALVE SPRINGS

WORN VALVE GUIDES

LEAKING HEAD GASKET STUCK CHOKE VALVE,

LEAKING INTAKE OR

CARBURETOR GASKETS

CHOKED MUFFLER

FIG. A

FIG. B

FIG. C

VACUUM MANIFOLD

FIREWALL

INTAKE MANIFOLD

ADAPTOR

MANIFOLD

PIPE PLUG