Loading ...

Loading ...

Loading ...

31-5000485 Rev. 4 17

Fine Tuning

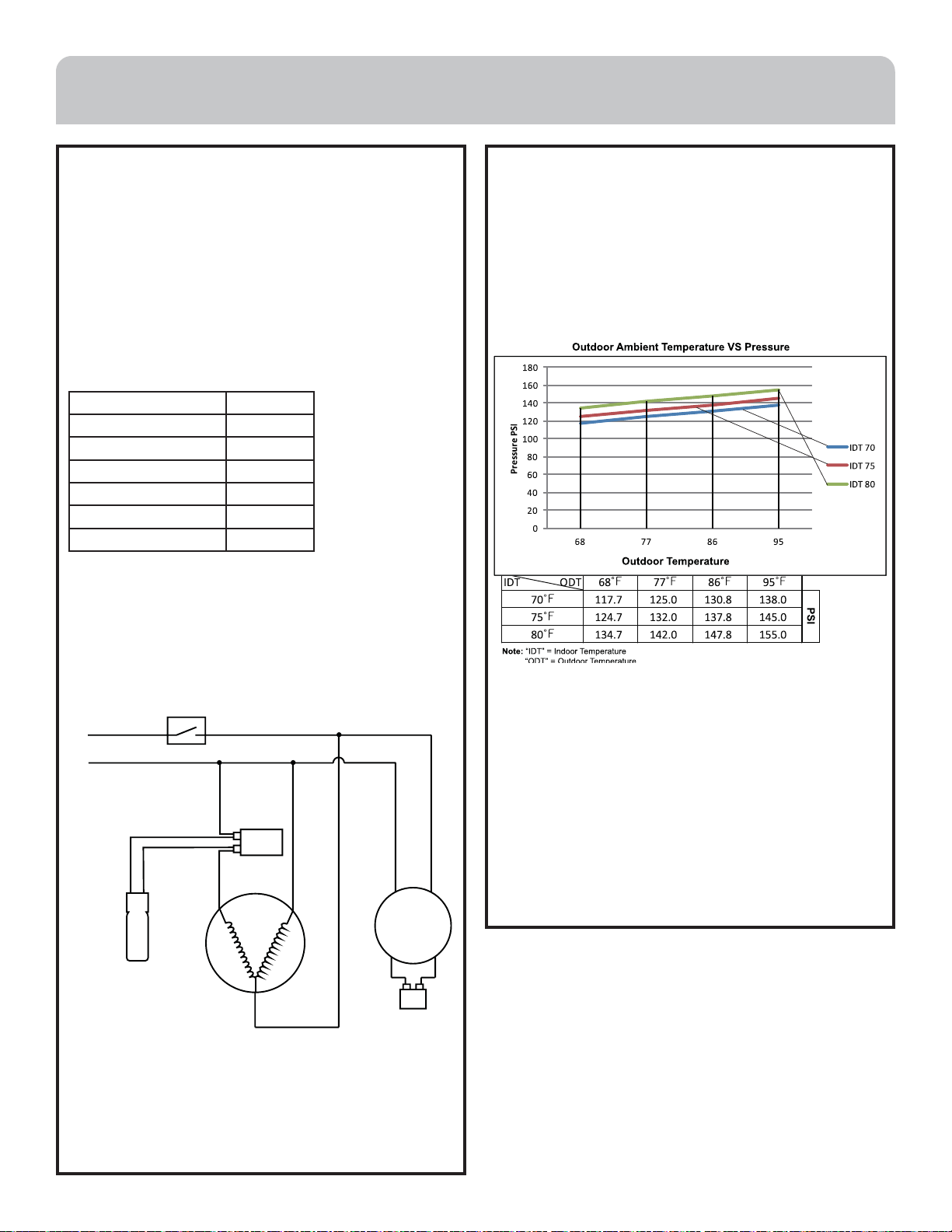

1. Allow the system to operate for at least 20 minutes

before checking refrigerant temperature and pressure.

2. Perform an air flow calculation to ensure the blower

is delivering the correct volume of air at the pressure

intended for the distribution system.

3. When the above are completed, verify that the

operating temperature and pressure comply with the

chart.

NOTE: “IDT” = Indoor Temperature

“ODT” = Outdoor Temperature

1. Remove refrigerant if the pressure is above the chart

value.

2. Add refrigerant if the pressure is below the chart value.

Perform an inspection of the entire installation and

finalize any items needed for completion. Review the

system operation, thermostat functions, and warranty

policy with the owner.

Leave this manual at the jobsite for future reference.

INSTALLATION INSTRUCTIONS

Hard Start Kits for 14-SEER Side

Discharge ODU

When inconsistent compressor starts are found, it is an

approved fix to add a locally sourced “Hard Start” kit. A kit

must include a capacitor and a relay. Replacing the OEM

capacitor with one that has a higher micro-fared rating IS

NOT an authorized repair and will void the warranty of the

product.

Selecting the Correct Kit

Hard start kits are sized by compressor horsepower (HP).

Use the chart below

Model HP

UUC112WC* 1

UUC118WC* 1.5

UUC124WC* 2

UUC130WC* 2.5

UUC136WC* 3

UUC148WC* 4

Installing Kit

The hard start kit must be installed in parallel with the

compressor capacitor. To do this, connect the leads from

the kit to either side of the compressor capacitor. The

kit must also be secured to the chassis of the unit, and if

required, grounded.

Run

Compressor

Capacitor

Fan

Capacitor

Fan

Compressor

Start

Contactor

L1

L2

Common

Hard Start

Kit

BK

BK

BK

BK

BL

BL

BL

WH

OR

RD

RD

Loading ...

Loading ...

Loading ...