Loading ...

Loading ...

Loading ...

16 31-5000485 Rev. 4

INSTALLATION INSTRUCTIONS

Start-up

Operation of the unit is automatic and will provide cooling

depending on the setting of the thermostat.

IMPORTANT

All panels must be installed, the main power turned on,

and the termostat properly connected before operating

the unit.

1. Set thermostat system switch to “Off” position and

fan switch to “Auto” position, Turn the power supply

breaker on.

2. Set the fan switch to “On” and make sure the blower

operates.

3. Return the fan switch to “Auto” and wait until the

blower stops. Set the system switch to “Cool” and

lower thermostat set point to coldest setting. The

compressor, condenser fan, and evaporator blower will

start. Cool air will be supplied after several minutes of

run time.

4. Proceed to the “Fine Tuning” section of these

instructions.

Leak Testing Evacuation, and Charging

The condensing unit is supplied with an R-410A charge

sufficient for most matching evaporator units. Charge

must be added for interconnecting tubing.

R=T X (L-25)ft

R (oz): Additional refrigerant to be charged

L (ft): The length of the liquid pipe

T (oz): The quantity of the charged refrigerant per

additional foot

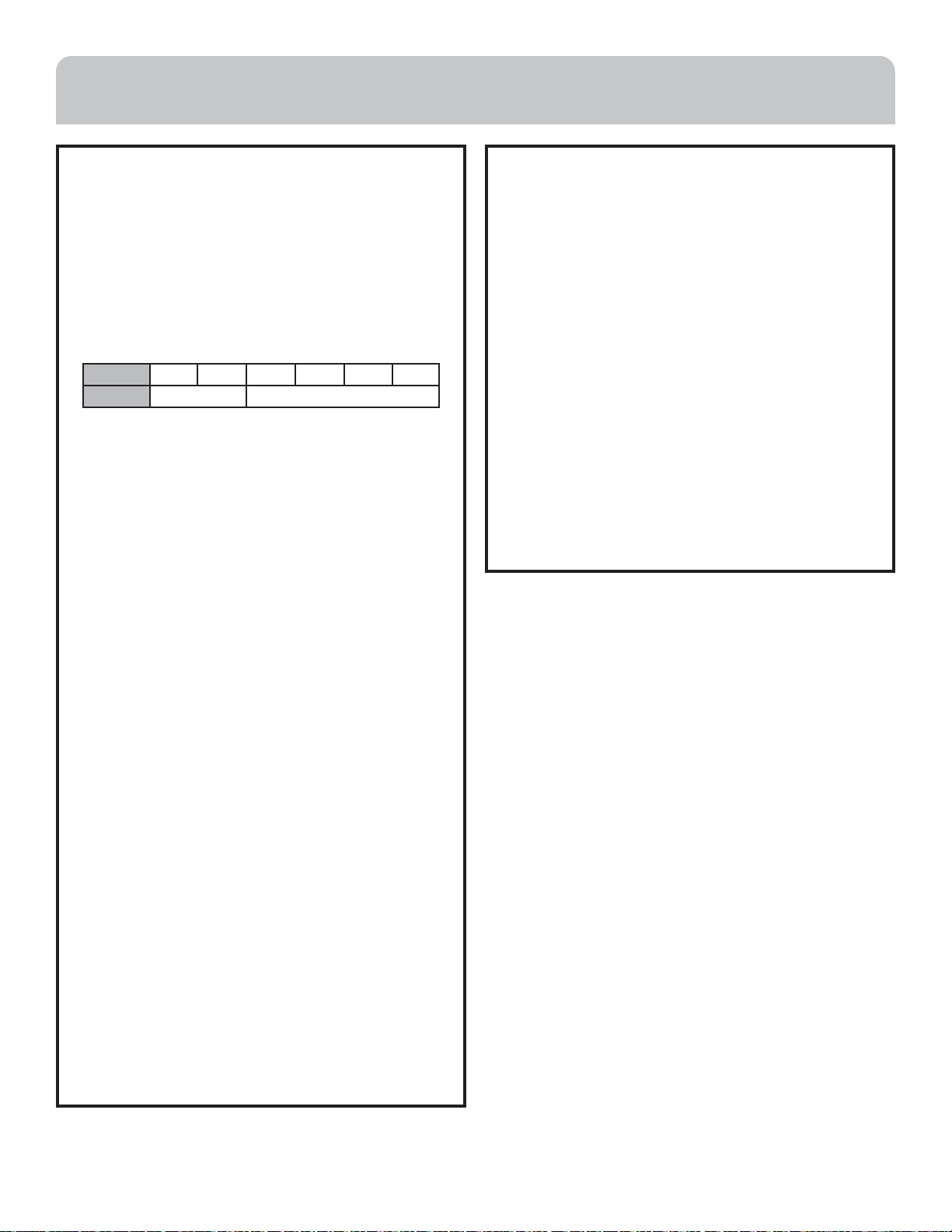

Model 12K 18K 24K 30K 36K 48K

oz/ft 0.16 0.32

The service valves are shipped in the closed position and

should not be opened until final connections, evacuation,

and additional charging are completed.

The recommended procedure for leak test, evacuation,

and charging is outlined below:

1. Complete the final piping connections to the indoor

and outdoor units.

2. Remove the service core from both lines, and connect

a charging manifold to the service ports on the service

valves.

3. Pressurize the lines and evaporator with 500 PSI of

dry nitrogen. Leak check all connections with either

an electronic detector or specialized liquids. Maintain

pressure for at least 30 minutes.

4. Release the nitrogen and connect a vacuum pump to

the manifold center connection. Start the pump and

open the manifold valves.

5. Evacuate to 350 microns or less. Close the manifold

valves and shut off the pump. If the vacuum level

does not rise more than 150 microns in one minute,

the evacuation is considered complete. Otherwise,

the system is indicating either a leak or there is still

moisture present.

6. If a leak is found, repair as necessary and repeat steps 3,

4, and 5. If there are no leaks, continue with Step 5 until

at least 350 microns is attained.

7. Close the manifold valves and disconnect the vacuum

pump. Reinstall the valve cores and add refrigerant

in the amount shown in the charging section of this

manual.

8. Remove the caps from the services valves. Open the

valves to the fully ‘back-seated’ position. Replace

service valve caps and tighten securely.

Loading ...

Loading ...

Loading ...