Loading ...

Loading ...

Loading ...

TP-7092 2/21 25Section 2 Generator Set Operation

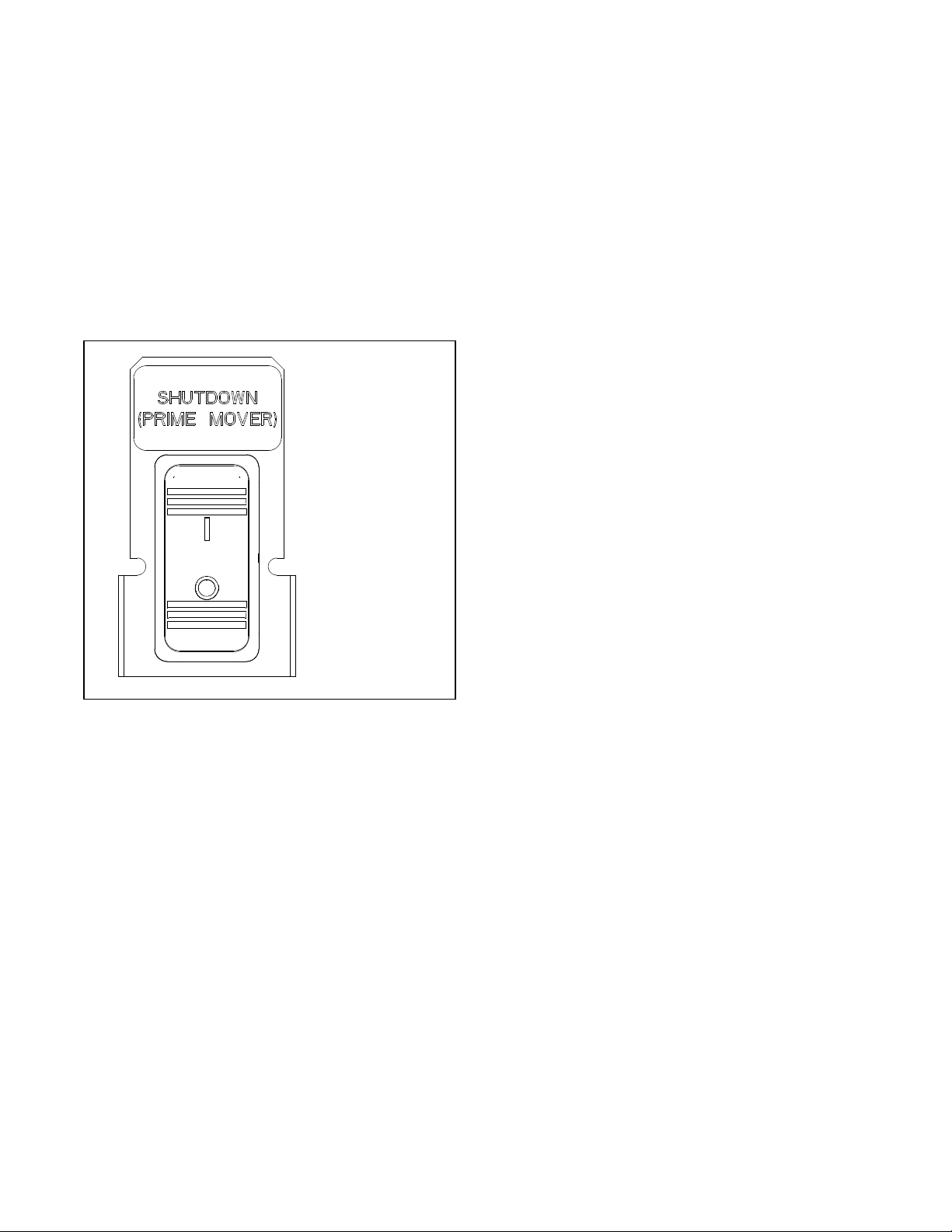

Shutdown Switch

The generator set may be equipped with a Shutdown

switch. See Figure 2-2. This switch, also referred to as

the Engine Shutdown switch, commands an immediate

shutdown and prevents an engine start if the switch is

turned to the off (open, O) position. When the shutdown

switch is activated, the controller display shows Emerg

Stop Shutdwn.

The switch is a mechanical, rocker-style switch. Press O

to prevent engine start during generator set service.

Press I to allow the engine to start and run.

See Figure 2-2 for switch connections.

dwg GM111084

I = On. The engine

is allowed to start.

O = OFF. Engine

shuts down, will not

start.

Figure 2-2 Shutdown Switch

2.3.5 Engine Start Crank Cycle

The controller attempts to start the generator set three

times (three crank cycles, 15 seconds crank and

15 seconds off). If the generator set does not start in

three attempts, the system shuts down on an overcrank

fault. See Section 2.5.

Cranking 1, 2, and 3 are displayed during the crank

cycle. Pressing the OFF button during the crank cycle

stops the cranking. No other buttons are acknowledged

during the crank cycle.

20 kW Models (RDC2.4 v1.4.4)

For RDC2.4 controllers with firmware version 1.4.4 or

later, the 20 kW models will perform two crank cycles

with 3 starting attempts during each cycle. The

controller attempts to start the generator set three times

(three starting attempts, 15 seconds crank and

15 seconds off). If the generator set does not start in

three attempts, the controller pauses for 45 seconds,

and then performs another set of 3 starting attempts. If

the generator set does not start during these crank

cycles, the system shuts down on an overcrank fault.

See Section 2.5.

2.3.6 Engine Cooldown

The engine cooldown time delay allows the engine to

run after the loads have been removed.

The engine cooldown time delay is set to 5 minutes. The

engine stops before the cooldown time delay expires if

the temperature drops below the cooled-down

temperature level, or if the temperature rises above the

high limit during the cooldown cycle.

If a transfer switch other than the Model RXT is used, an

additional engine cooldown time delay may be

programmed on the transfer switch. To allow the smart

engine cooldown on the RDC2 controller to operate

most efficiently, set the cooldown time on the transfer

switch controller to zero or the minimum time allowed.

Refer to the instructions provided with the transfer

switch for more information.

2.3.7 Automatic Operation with Model

RXT Transfer Switch

The Model RXT transfer switch connects to the RDC2

controller through the ATS interface board on the

transfer switch. Also see the Model RXT Transfer

Switch Operation/Installation Manual for more

information about transfer switch operation.

The controller must be in AUTO mode for automatic

transfer switch operation.

Automatic Start

The RDC2 controller receives utility source voltage

sensing data from the Model RXT transfer switch.

1. If the utility source voltage falls below an

acceptable level, the controller starts the engine

start time delay.

2. If the utility source is not restored before the time

delay expires, the generator set starts.

3. After the Normal-to-Emergency time delay, the

ATS is signaled to transfer the load to the

emergency source.

Loading ...

Loading ...

Loading ...