Loading ...

Loading ...

Loading ...

7. ELECTRICAL WIRING

Electrical shock hazard.

Disconnect power at fuse box or service panel before making

any electrical connections.

Unit MUST be grounded to electrical service panel.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

NOTE: All electrical work MUST conform with the

requirements of local codes and ordinances and the

National Electrical Code ANSIiNFPA-No. 70-1990 or

current edition. Provide line voltage power supply from a

separate fused circuit with a disconnect switch located

within sight of the unit.

For access, remove the burner access panel. See

FIGURE 1 for access panel location. Wiring MUST be

protected from possible mechanical damage.

Line Voltage Wiring

Connections for line voltage are made in the unit control box

area. For access, remove the burner access panel.

Ground Connections

Do NOT complete line voltage connections until unit is

permanently grounded. All line voltage connections and the

ground connection MUST be made with copper wire.

A ground lug is installed in the control box area for the

appropriate size from the unit to a grounded connection in

the electrical service panel or a properly driven and

electrically grounded ground rod. See warning above.

Line Connections

Complete the line service connections to the contactor 'L'

terminals inside the control box area. Refer to applicable

wiring diagram. Check all screw terminals to ensure they

are tight.

THERMOSTAT/HEAT ANTICIPATOR

The location ofthe thermostat has an important effect onthe

operation of the unit. FOLLOW THE INSTRUCTIONS

INCLUDED WITH THE THERMOSTAT FOR CORRECT

MOUNTING AND WIRING.

Set the thermostat heat anticipator in accordance with

thermostat instructions.

Final Electrical Check

1. Make a final wiring check to be sure system is correctly

wired. Inspect field installed wiring and the routing to

ensure that rubbing or chafing due to vibration will not

Occur.

NOTE: Wiring MUST be installed so it is protected from

possible mechanical damage.

8. DUCTWORK

Maximum recommended velocity in trunk ducts is 1000 feet

per minute. Velocity in branches should not exceed 800 feet

per minute.

round connection, Use a copper conductor of the

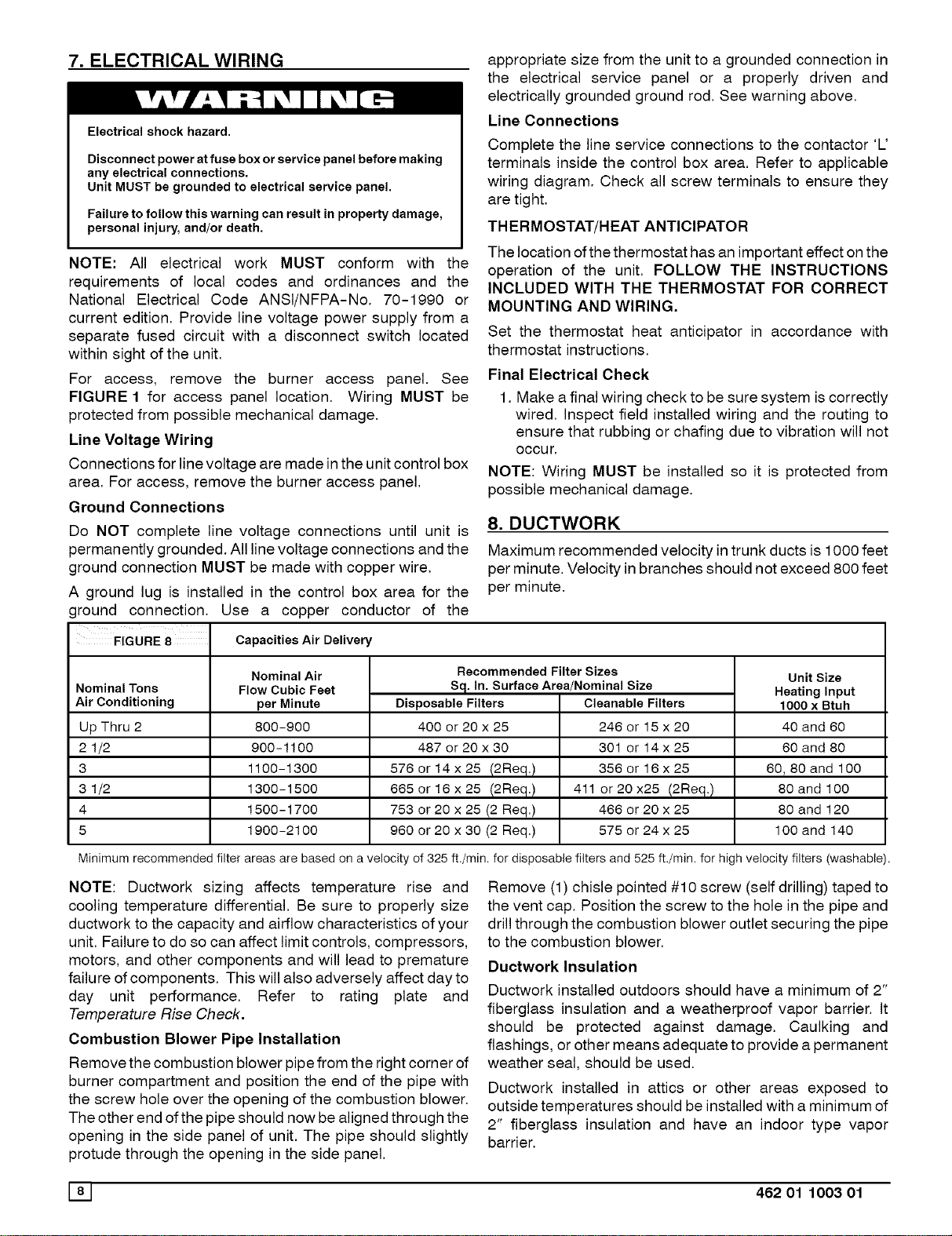

FIGURE 8 Capacities Air Delivery

Nominal Tons

Air Conditioning

Up Thru 2

2 1/2

3

3 1/2

4

5

Nominal Air

Flow Cubic Feet

per Minute

800-900

900-1100

1100-1300

1300-1500

1500-1700

1900-2100

Recommended Filter Sizes

Sq. In. Surface Area/Nominal Size

Disposable Filters

400 or 20 x 25

487 or 20 x 30

576 or 14 x 25 (2Req.)

565 or 16 x 25 (2Req.)

753 or 20 x 25 (2 Req.)

960 or 20 x 30 (2 Req.)

Cleanable Filters

246 or15x20

301 or 14x25

356 or16x25

411 or 20 x25 (2Req.)

466 or 20 x 25

575 or 24 x 25

UnitSize

Heatinglnput

1000 x Btuh

40 and 60

60 and 80

60, 80 and 100

80 and 100

80 and 120

100 and 140

Minimum recommended filter areas are based on a velocity of 325 ft,/min, for disposable filters and 525 ft./min, for high velocity filters (washable).

NOTE: Ductwork sizing affects temperature rise and

cooling temperature differential. Be sure to properly size

ductwork to the capacity and airflow characteristics of your

unit. Failure to do so can affect limit controls, compressors,

motors, and other components and will lead to premature

failure of components. This will also adversely affect dayto

day unit performance. Refer to rating plate and

Temperature Rise Check.

Combustion Blower Pipe Installation

Remove the combustion blower pipe from the right corner of

burner compartment and position the end of the pipe with

the screw hole over the opening of the combustion blower.

The other end of the pipe should now be aligned through the

opening in the side panel of unit. The pipe should slightly

protude through the opening in the side panel.

Remove (1) chisle pointed #10 screw (self drilling) taped to

the vent cap. Position the screw to the hole in the pipe and

drill through the combustion blower outlet securing the pipe

to the combustion blower.

Ductwork Insulation

Ductwork installed outdoors should have a minimum of 2"

fiberglass insulation and a weatherproof vapor barrier. It

should be protected against damage. Caulking and

flashings, or other means adequate to provide a permanent

weather seal, should be used.

Ductwork installed in attics or other areas exposed to

outside temperatures should be installed with a minimum of

2" fiberglass insulation and have an indoor type vapor

barrier.

W 462 01 1003 01

Loading ...

Loading ...

Loading ...