Loading ...

Loading ...

Loading ...

work the blade up and down while

rotating the clamp (in a counter-

clockwisedirection).

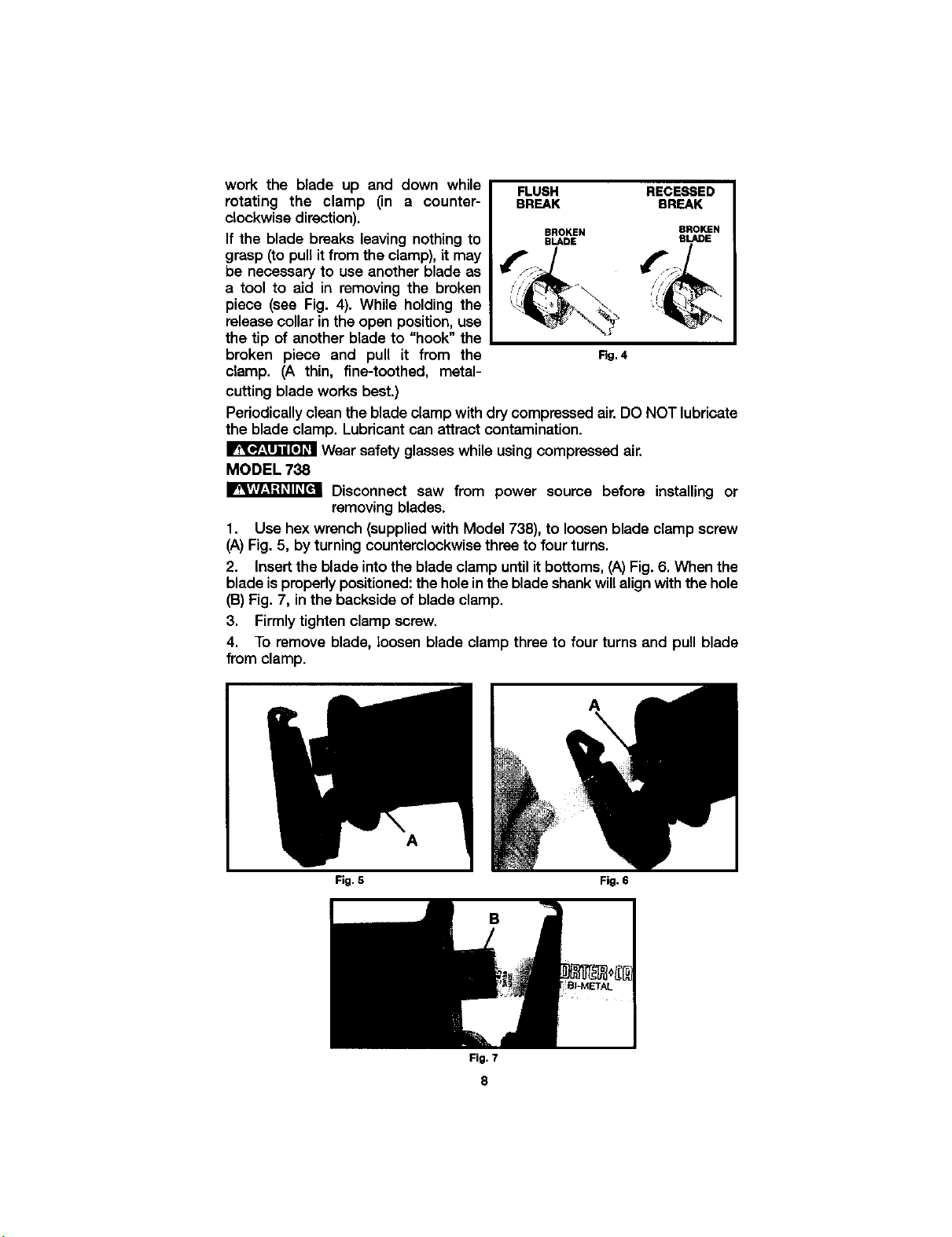

If the blade breaks leaving nothing to

grasp (topull itfrom the clamp), it may

be necessary to use another blade as

a tool to aid in removingthe broken

piece (see Fig. 4). While holding the

release collar in the open position,usa

the tip of another blade to "hook" the

broken piece and pull it from the

clamp. (A thin, fine-toothed, metal-

cutting blade works best.)

FLUSH RECESSED

BREAK BREAK

BROKEN BROKEN

BLADE BLADE

Rg. 4

Periodically clean the blade clamp with dry compressedair.DO NOT lubricate

the blade clamp. Lubricant can attract contamination.

Wear safety glasses while using compressed air.

MODEL 738

I_g7/_]'_'_l Disconnect saw from power source before installing or

removing blades.

1. Use hex wrench (suppliedwith Model 738), to loosen blade clamp screw

(A)Fig. 5, byturning counterclockwisethree to four turns.

2. Insertthe blade intothe blade clamp until itbottoms, (A)Fig. 6. When the

bladeisproperly positioned:the holeinthe bladeshank willalignwith the hole

(B)Fig. 7, in the backside of bladeclamp.

3. Firmlytighten clamp screw.

4. To remove blade, loosen blade clamp three to four turns and pull blade

from clamp.

A

A

Fig. S

B

Fig. 6

Fig. 7

8

Loading ...

Loading ...

Loading ...