Loading ...

Loading ...

Loading ...

BEFORE YOU START TO WORK

Select the blade best suited for the material to be cut (see ACCESSORIES).

For greatest economy, use the shortest blade suitable for the thickness of the

material to be cut.

Be sure the material to be cut is rigid. Small work pieces should be securely

clamped in a bench vise or with clamps to the work table. As the work

progresses in scrollor curved cut-out pieces, the material may be readjusted

to accommodate the movement of the saw. If the work is large enough, it may

be held only by hand across saw horses. The saw cuts freely with only slight

feed pressure. Forcing the saw will not make it cut faster.

SAWING WOOD

The TIGER SAW®is used much the same as a hand saw in that it is moved

toward the operator during the cutting operation. However, since the blade

cuts on the up-stroke instead of the down-stroke as in the case of the hand

saw, the good or finishside of the work should face down during the cutting

operation.

PLUNGE CUTS

The TIGER SAVWcan be used for plunge cutting wood, plywood, wallboard,

and plastic materials. DO NOT attempt to plunge cut metal.

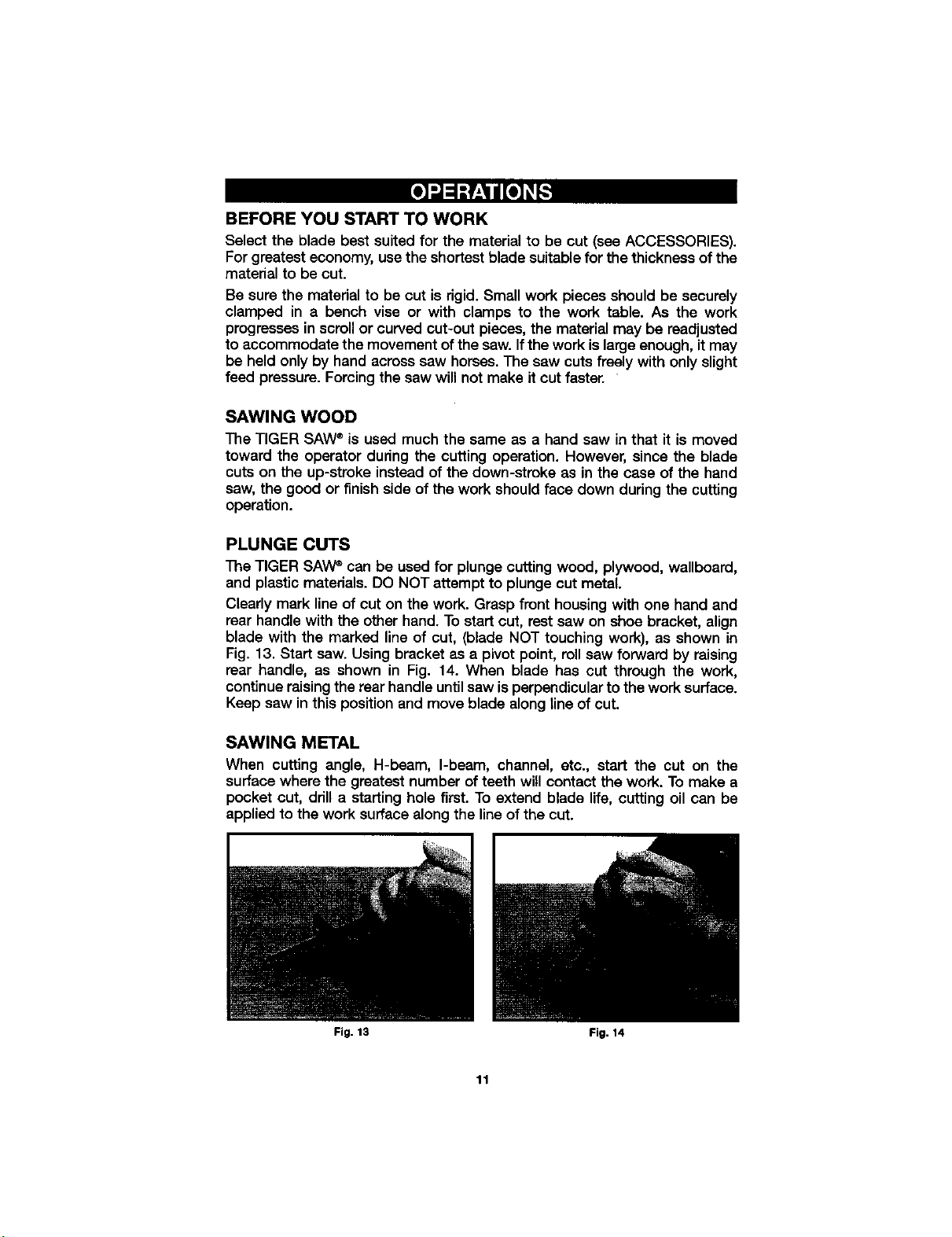

Clearly mark line of cut on the work. Grasp front housing with one hand and

rear handle with the other hand. To start cut, rest saw on shoe bracket, align

blade with the marked line of cut, (blade NOT touching work), as shown in

Fig. 13. Start saw. Using bracket as a pivot point, roll saw forward by raising

rear handle, as shown in Fig. 14. When blade has cut through the work,

continue raising the rear handle until saw is perpendicular to the work surface.

Keep saw in this position and move blade along line of cut.

SAWING METAL

When cutting angle, H-beam, I-beam, channel, etc., start the cut on the

surface where the greatest number of teeth will contact the work. To make a

pocket cut, drill a starting hole first. To extend blade life, cutting oil can be

applied to the work surface along the line of the cut.

Fig. 13 Fig. 14

11

Loading ...

Loading ...

Loading ...