Loading ...

Loading ...

Loading ...

English 8

When brazing the refrigerant piping, perform nitrogen re-•

placement fi rst, or perform the brazing while feeding nitro-

gen into the refrigerant piping. (Refer to Fig. 6)

Refrigerant piping

Part to be brazed

Taping

Pressure-reducing valve

hands

valve

Nitrogen

Nitrogen

Fig. 6

CAUTION

When brazing piping while feeding nitrogen inside the •

piping, make sure to set the nitrogen pressure to 2.9 psi or

less using the pressure reducing valve.

(This pressure is such that a breeze is blown to your cheek.)

DANGER

Use of oxygen could result in an explosion resulting in •

serious injury or death. Only use dry nitrogen gas.

Refrigerant gas may produce toxic gas if it comes in contact •

with fi re such as from a fan heater, stove or cooking device.

Exposure to this gas could cause severe injury or death.

NOTE

Do not use fl ux when brazing refrigerant piping. Therefore, •

use the phosphor copper brazing fi ller metal (BCuP) which

does not require fl ux.

Flux has an extremely negative effect on refrigerant piping

systems. For instance, if chlorine based fl ux is used, it will

cause piping corrosion. Flux containing fl uorine will damage

refrigerant oil.

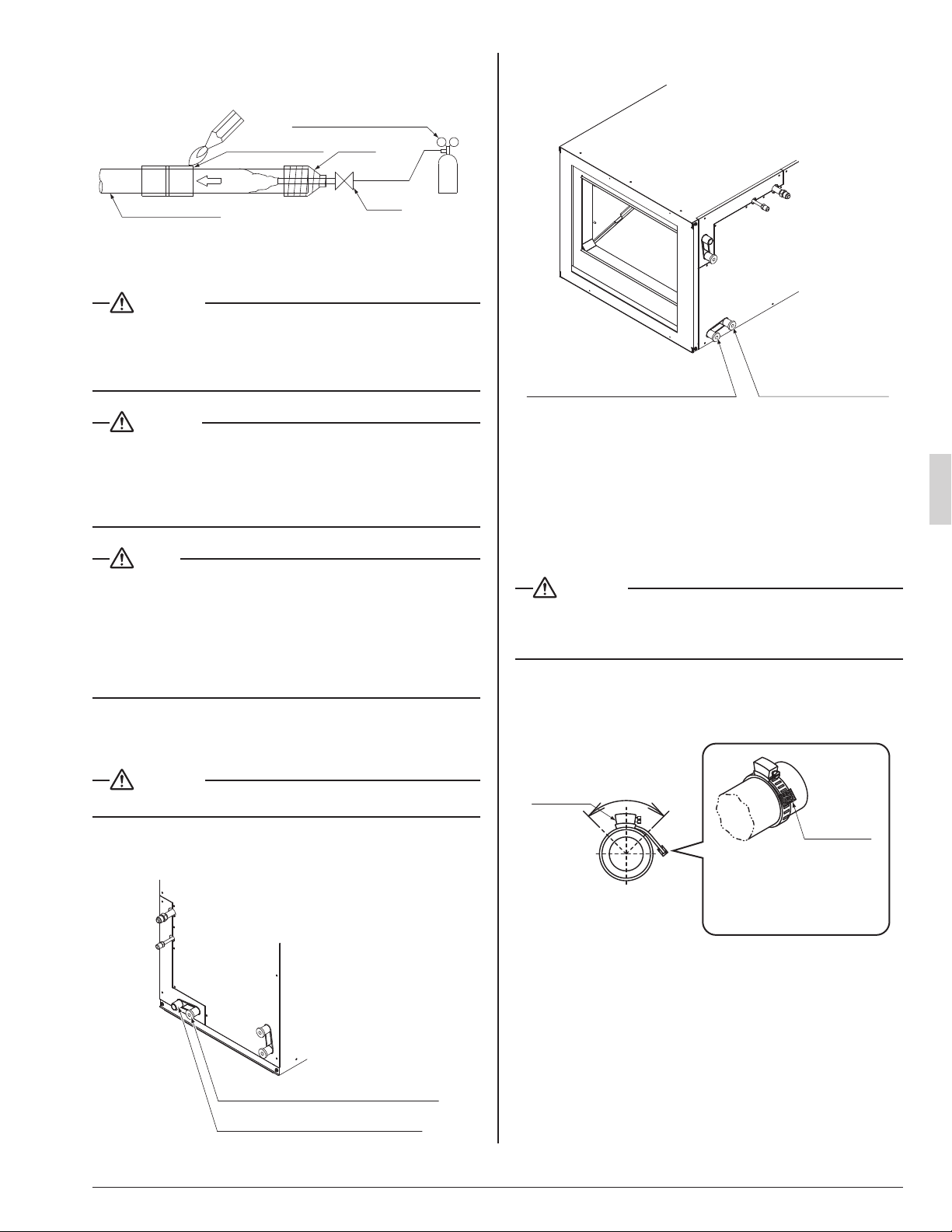

DRAIN PIPING WORK6.

CAUTION

Make sure all water is out before making the duct connection.

•

Install drain piping as described Fig. 7.(1)

Secondary drain piping connection hole

Primary drain piping connection hole

In case of vertical installation

Fig. 7-1

Primary drain piping connection hole

Secondary drain piping

connection hole

In case of horizontal installation

Fig. 7-2

Perform drain work so that the unit is drained thoroughly. •

(Be sure to insulate the following 2 locations since

condensation may cause water leakage.)

Be sure to use the included Drain hose (5) and Metal •

clamp (4).

Insert the Drain hose (5) up to the step on the drain

socket. Within the range of the tape section at the

end of the inserted hose, tighten the Metal clamp (4)

to the torques of 0.99 ± 0.1 lbf·ft (11.9 ± 1.2 lbf·in).

CAUTION

Do not tighten the Metal clamp (4) to torques exceeding the

•

specifi cation. Otherwise, the Drain hose (5), the socket, and

the Metal clamp (4) may become damaged.

To avoid the Sealing pad (large) (9) from tearing at the •

edge of the Metal clamp (4), either affi x a plastic tape

on the edge of the Metal clamp (4) or bend the end of

the Metal clamp (4) inward as shown in the fi gure.

Plastic tape

To avoid tearing the Sealing

pad (large) (9), affix a

plastic tape.

Tightening

section

Approx. 90°

<When affixing plastic tape>

Cross section A-A

01_EN_3P250363-4E.indd 801_EN_3P250363-4E.indd 8 6/9/2016 4:56:48 PM6/9/2016 4:56:48 PM

Loading ...

Loading ...

Loading ...