Loading ...

Loading ...

Loading ...

7 English

Refer to Table 2 for the processing dimensions of the •

fl are.

Use the fl are nut provided with the unit.•

Apply ether oil or ester oil only to inner side of the •

fl are and screw in the fl are nut three to four turns fi rst

by hand at the time of connecting the fl are nut.

(Refer to Fig. 4)

Fig. 4

Apply ester oil or ether oil

only to inner side of flare.

•

Refer to Table 2 for the corresponding tightening torque.•

Table 2

Pipe

size

Tightening torque

Flare

dimensions

A (in.)

Flare shape

φ 3/8 26.7 ±2.6 lbf·ft

0.504 – 0.520

9

0

˚

±

2

˚

4

5

˚

±

2

˚

A

R0.016-0.031

φ 5/8 50.6 ±5.0 lbf·ft

0.760 – 0.776

CAUTION

Do not excessively tighten the fl are nut.•

Doing so will break the fl are nut and refrigerant leakage may

result.

Make sure that all parts around the fl are are free of oil. •

The drain pan and the resin part may be deteriorated if oil is

attached.

If no torque wrenches are available, refer to Table 3 as a •

standard.

When the fl are nut is tightened with the spanner, the

tightening torque should increase suddenly. Tighten the

fl are nut further for the corresponding angle shown in

Table 3.

Table 3

Pipe size Further tightening angle

Recommended arm length of

tool

φ 3/8 60 to 90 degrees Approx. 7-7/8 in.

φ 5/8 30 to 60 degrees Approx. 11-13/16 in.

On completion of installation work, (2) check that there is no

gas leakage.

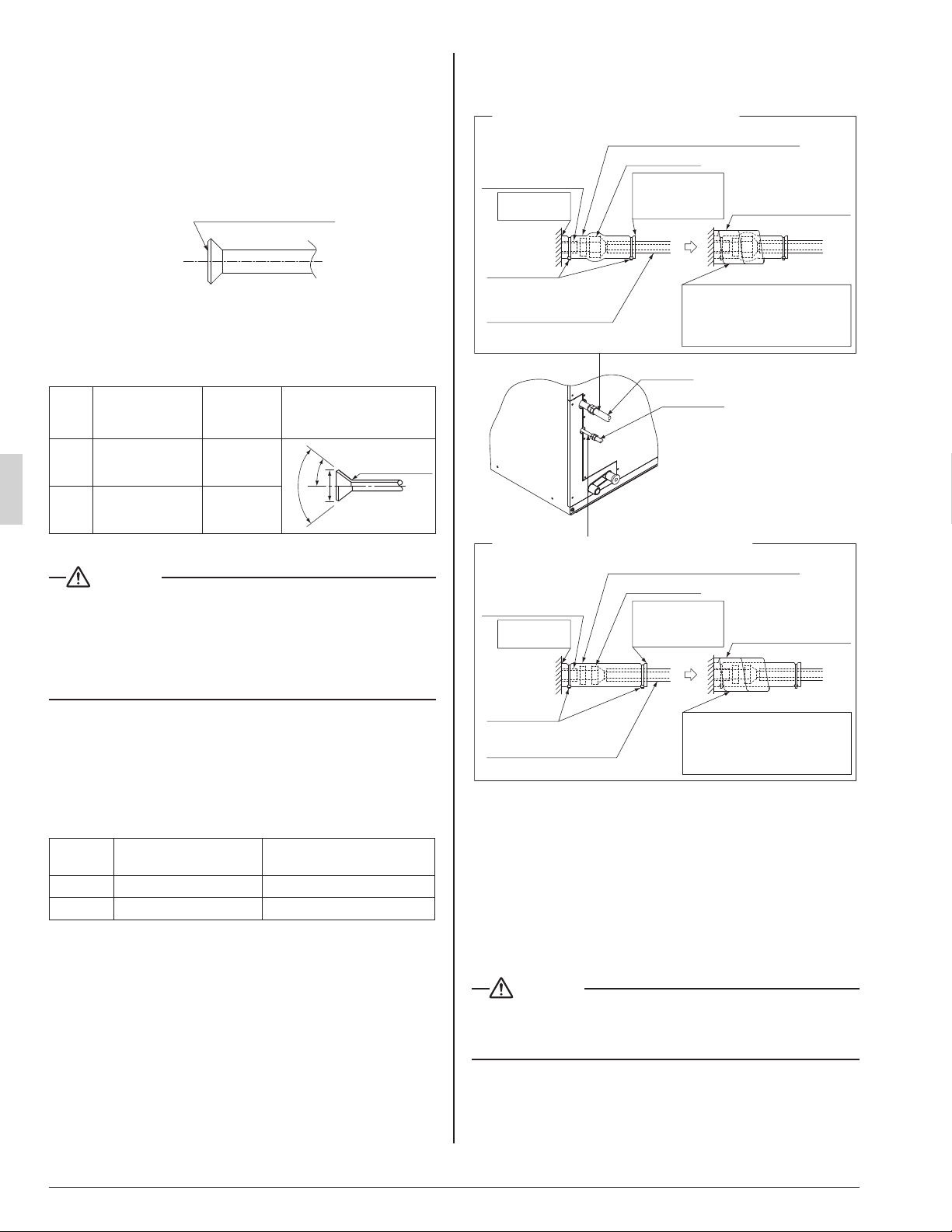

Refer to the illustration on the right-hand side and be sure (3)

to perform heat insulation work on the piping joints after

gas leakage checks. (Refer to Fig. 5)

Heat insulation procedure for gas piping

Insulation material

for piping

(on unit side)

Insulation material

for piping (field supply)

Make sure that

the seam faces

upward.

Clamp

material (1)

(accessory)

Gas pipe

Liquid pipe

Flare nut joint

Attached to

the surface.

Insulation for fitting (7) (accessory)

Sealing pad (small) (8)

(accessory)

Wrap the Sealing pad (small) (8)

around the portion from the

surface of the main unit to the

upper part of the flare nut joint.

Insulation material

for piping (field supply)

Wrap the Sealing pad (small) (8)

around the portion from the

surface of the main unit to the

upper part of the flare nut joint.

Fig. 5

Heat insulation procedure for liquid piping

Insulation material

for piping

(on unit side)

Make sure that

the seam faces

upward.

Clamp

material (1)

(accessory)

Main unit

Flare nut joint

Attached to

the surface.

Insulation for fitting (6) (accessory)

Sealing pad (small) (8)

(accessory)

Use the Insulation for fi tting (6) and (7) provided to the •

liquid piping and gas piping, respectively, and conduct

heat insulation work.

(Tighten both edges of the Insulation for fi tting (6) and

(7) for each joint with the Clamp material (1).)

Make sure that the joint of the Insulation for fi tting (6) •

and (7) for the joint on the liquid piping and gas piping

side faces upward.

Wrap the Sealing pad (small) (8) around the Insulation •

for fi tting (6) and (7) for the joint (fl are nut part).

CAUTION

Be sure to insulate any fi eld piping all the way to the piping •

connection inside the unit. Any exposed piping may cause

condensation or burns if touched.

01_EN_3P250363-4E.indd 701_EN_3P250363-4E.indd 7 6/9/2016 4:56:47 PM6/9/2016 4:56:47 PM

Loading ...

Loading ...

Loading ...